Introduction:

ultrasonic soldering is a fluxless soldering process that uses high-frequency sound waves to clean metal surfaces and enable the solder to flow, all without the need for chemical flux.

It's primarily used for joining materials that are traditionally difficult to solder, such as aluminum, stainless steel, and ceramics, because their surfaces instantly form a tough, stable oxide layer that prevents wetting.

Parameter:

| Model No. | RPS-T |

| Ultrasonic Frequency | 40Khz |

| Maximum Output | 800 Watt |

| Temperature Range | 150 ~ 400 °C |

| Power Supply | 220V / 50-60 Hz |

| Ultrasonic Generator | Size | 250(W) x 310(L) x 135(H) mm |

| Weight | 3 Kg |

| Feature | Ultrasonic Amplitude Adjustable |

| Pot dimension | 5*8 mm |

| Avail Soldering Matrial | ITO Glass, AL, Mo, Cu etc., |

Ultrasonic soldering is used to join materials with either a metallurgical or mechanical bond.

A metallurgical bond is formed when the oxide from the base metal is removed through ultrasonic cavitation and implosion in the solder. The solder then comes in to contact with the base metal and the ionic attraction between the two forms a bond. A tin or lead solder bonded to copper is an example of this.

The Core Principle: How It Works

The magic of ultrasonic soldering lies in two key phenomena caused by high-frequency vibrations:

Acoustic Cavitation: The soldering tool (called a sonotrode or horn) vibrates at an ultrasonic frequency (typically 20 kHz to 40 kHz or higher). These vibrations are transmitted into the molten solder bath or the solder joint itself. This intense agitation creates and collapses millions of microscopic bubbles in the liquid solder—a process called cavitation.

Oxide Removal: The implosion of these cavitation bubbles releases a tremendous amount of energy locally. This blast of energy is powerful enough to scrub away the oxide layer on the metal surfaces being joined. It literally shatters and disperses the oxides, exposing a perfectly clean, active metal surface.

Once the oxide barrier is removed, the clean molten solder can immediately wet and bond with the base metal, forming a strong metallurgical joint—all without any flux.

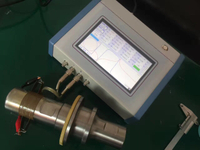

Key Components of an Ultrasonic Soldering System

A typical system consists of:

Ultrasonic Generator: The power supply that converts standard electrical power into high-frequency electrical energy.

Transducer (or Converter): Converts the high-frequency electrical signal from the generator into high-frequency mechanical vibrations.

Booster / Acoustic Horn: Modifies the amplitude of the mechanical vibrations.

Sonotrode (Soldering Tip): This is the working tip that delivers the ultrasonic vibrations to the solder and the workpiece. It can be designed as a simple iron tip or as part of a larger soldering pot.

Common Ultrasonic Soldering Techniques

There are two main ways this technology is applied:

Ultrasonic Soldering Iron: This looks and operates much like a standard soldering iron, but the tip vibrates ultrasonically. You apply the vibrating tip to the solder and the joint. It's ideal for localized repairs and small-scale work.

Ultrasonic Solder Pot: A small pot filled with molten solder is ultrasonically activated. To solder a component, you simply dip its pre-tinned wires or leads into the pot. The cavitation in the pot instantly cleans and tins the surface. This is extremely common in the electronics industry for tinning component leads, especially for aluminum-wired components.

When to use Ultrasonic Soldering

There are two main reasons for using Ultrasonic Soldering:

1. To eliminate the need for flux in the soldering process

2. To apply solder to ceramics and similar materials

The advantages of removing flux from the process are that there is no need for post-process

cleaning and wicking caused by surface tension from the flux is removed. Eliminating post-process

cleaning has the obvious benefit of cost saving for both the process and the flux itself. The benefit of

eliminating wicking is that the solder coating on the base material can be better controlled.

Advantages and Disadvantages

Advantages:

Fluxless Process: Eliminates the cost of flux and, more importantly, prevents issues like corrosion and electrical leakage from flux residues. This is critical for high-reliability electronics, medical devices, and components that must remain clean.

Joins "Unsolderable" Materials: Makes it possible to solder aluminum and other difficult metals.

Excellent Wetting: The cavitation action ensures superior wetting and a strong, reliable bond.

Eco-Friendly and Safer: No harmful flux fumes are produced, creating a healthier work environment.

Application

* Aluminum components

* Ferrite components

* Glass components

* Silicon wafers

* Ceramic components

* Semiconductor chips

* Metals etc.