What is Ultrasonic Stress Relief Equipment?

I. Basic Concepts and Principles

What is Ultrasonic Stress Relief?

It is an advanced process that uses high-power, low-frequency ultrasonic energy to vibrate metal components (especially welds), thereby homogenizing, reducing, and redistributing their internal residual stress. It is a non-thermal, non-destructive stress relief method.

How does it work?

The equipment generates low-frequency (typically 15kHz-40kHz), high-energy ultrasonic waves. This mechanical vibration energy is transmitted to the workpiece through a transducer and a special tool head (needle). When the vibration energy superimposes with the residual stress field within the material and reaches a certain level, it induces microscopic plastic deformation, thereby releasing and homogenizing the stress in areas with high residual stress peaks.

What are the advantages compared to traditional thermal stress relief (heat treatment)?

Comparison Items: Ultrasonic Stress Relief Traditional Thermal Stress Relief

Principle: Mechanical vibration, performed at room temperature; Overall or localized heating to high temperature and holding.

Efficiency: Very fast (in minutes), no cooling required; Very slow (in hours or even days), requires furnace cooling.

Energy Consumption: Extremely low (only equipment consumes electricity); Extremely high (heating furnace consumes a huge amount of energy).

Workpiece Deformation: Minimal, almost no macroscopic deformation; High risk, may cause thermal deformation.

Material Properties: Does not change the material's metallographic structure and hardness; May change the material's structure and hardness, leading to softening or oxidation and decarburization.

Applicability: Can be performed on large, installed structures on-site; Usually requires a large heat treatment furnace, limited by workpiece size.

Environmental Safety: No open flame, no high temperature, no harmful gases; High-temperature operation, fire risk, may generate exhaust gases.

II. Applications and Materials

Main Application Areas:

Post-weld treatment: Welds in pressure vessels, pipelines, ships, bridges, and heavy machinery.

Additive Manufacturing (3D Printing): Eliminates residual stress accumulated inside printed metal parts, preventing deformation and cracking.

Post-machining: Eliminates machining stress introduced by cutting, grinding, and other processes, improving dimensional stability.

Critical component maintenance: Stress control and life extension for in-service equipment.

Precision components in high-requirement fields such as aerospace and nuclear power.

Applicable materials?

Widely applicable: Common metals such as carbon steel, low-alloy steel, stainless steel, and aluminum alloys.

Partially applicable: Cast iron, certain tool steels (requires evaluation). Equipment parameters need to be adjusted for the acoustic characteristics of different materials.

Are there any limitations on workpiece shape and size?

Theoretically, there are no absolute limitations, but workpiece quality (weight) is critical. The equipment has an "effective processing weight range." If the workpiece is too light, energy will dissipate; if it is too heavy, longer processing time or multiple processing points are required. The equipment supplier will provide parameter recommendations based on your typical workpiece.

III. Operation and Process

What is the operating procedure?

Surface preparation: Clean the area to be processed (welds, etc.) and ensure good tool head contact.

Equipment settings: Set the frequency, power, and processing time according to the material, thickness, and process card.

Install the tool head: Secure the ultrasonic needle to the workpiece using a dedicated bracket or magnetic base.

Start processing: Start the equipment and move the needle at a stable speed along a predetermined path (e.g., weld seam).

Inspection: After processing, stress testing (e.g., blind hole method) can be performed to verify the effect.

How to determine the optimal process parameters?

Parameters (power, speed, mode) are mainly determined by material type, thickness, and weld seam type. It is strongly recommended that the equipment supplier provide a preliminary process database or conduct on-site process trials. Operators must receive professional training.

How to verify the effect?

Direct detection: Use X-ray diffraction or a blind hole stress detector to measure at the same location before and after processing, and compare the data.

Indirect verification: Judge by observing whether the deformation of the workpiece decreases or its fatigue resistance improves during subsequent processing or use.

IV. Equipment Selection and Maintenance

How to select the equipment model?

Main considerations:

Output power: Determines energy intensity, affecting processing depth and speed.

Frequency Range: Mainstream is 20kHz-35kHz; different frequencies are adaptable to different materials and structures.

Processing Weight Range: The effective workpiece weight range specified by the equipment.

Brand and Reliability: The quality of core components (transducer, generator) is crucial.

Supplier Service: Does the equipment provide comprehensive training, process support, and after-sales service?

What are the core components of the equipment? Are they easily damaged?

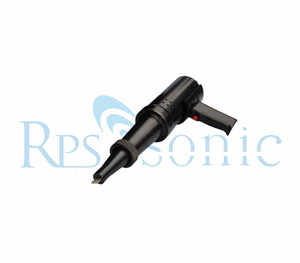

Core Components: Ultrasonic generator, transducer, amplitude transformer, tool head (needle).

Durability: Very durable under normal operation. The tool head is a consumable; the tip will wear down with prolonged use and needs to be replaced regularly. Avoid running the equipment for extended periods without load (needle not in contact with the workpiece), as this will damage the transducer.

What precautions should be taken for daily maintenance?

Keep the equipment clean and dry.

Regularly check cables and connectors for damage.

Handle the transducer and tool head with care to prevent drops and impacts.

Perform regular maintenance according to the manual.

V. Safety and Certification

Is the operation safe? What precautions should be taken? Intrinsically safe: No radiation, no high temperature.

Follow the equipment's safe operating procedures.

Does this technology have standard certifications?

Yes. Internationally, standards/specifications such as those of the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME) have introduced or recognized ultrasonic impact treatment (UIT/UIP) as a stress improvement method. When selecting this method, inquire with the supplier whether the equipment complies with relevant industry standards (such as specific standards for ships, pressure vessels, etc.).

English

English