What Is The Ultrasonic Rubber Cutter?

In rubber product processing workshops, traditional cutting processes have long faced pain points such as rough cuts, material damage, and low efficiency. Thick rubber is prone to cracking and delamination when cut, soft rubber sticks to the blade, and the precision of cutting irregularly shaped parts is difficult to control. Frequent blade changes further slow down production. The emergence of ultrasonic rubber cutters, with their innovative high-frequency vibration technology, breaks through the limitations of traditional cutting, injecting new momentum into the rubber processing industry with high efficiency, precision, and environmental friendliness, becoming an indispensable core piece of equipment in the production of high-end rubber products.

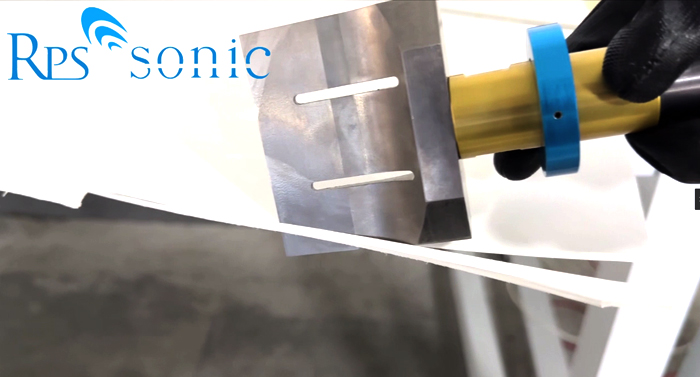

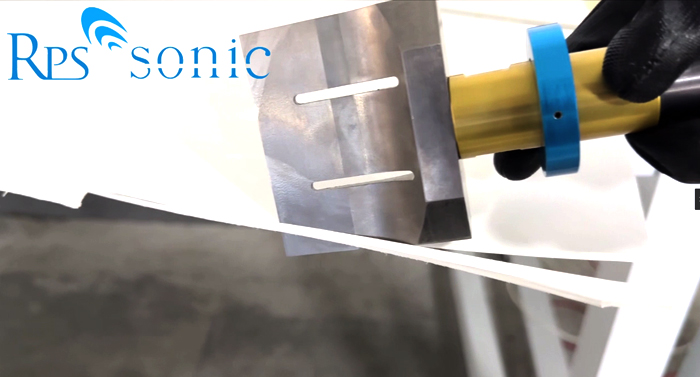

I. Core Principle: The core difference between ultrasonic rubber cutters and traditional blades lies in their non-contact, high-frequency vibration cutting principle, rather than relying on the pressure shearing of a sharp blade. The equipment converts ordinary electrical energy into a 20-40kHz high-frequency electrical signal through an ultrasonic generator. This signal is then converted into longitudinal mechanical vibration of the same frequency by a transducer, and the amplitude is amplified (typically 10-70μm) by an amplitude transformer before being transmitted to the cutting head.

This microscopic high-frequency vibration, occurring 20,000 to 40,000 times per second, instantly activates the rubber molecules in the cutting area when applied to the rubber material surface, breaking the molecular chain bonds and generating localized micro-frictional heat. This causes the rubber material to soften temporarily without damaging the substrate. The entire process requires no excessive pressure, achieving smooth cutting of the material through the dual effect of "vibration separation + micro-thermal fusion." This avoids damage caused by hard shearing and solves the problem of sticky materials adhering to the blade, falling under the typical category of "cold cutting" technology.

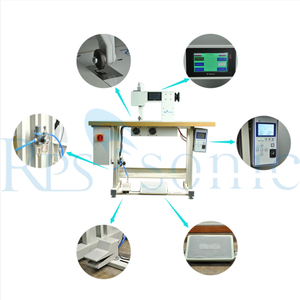

II. Core Structure: The ultrasonic rubber cutter is not a single blade, but a complete system composed of multiple precision components. Each component performs its specific function, ensuring stable and efficient cutting performance:

1. Ultrasonic Generator: As the power core, it converts 220V power frequency current into high-frequency, high-voltage electrical signals. It also features frequency adjustment and power control functions, allowing for precise parameter adaptation based on the rubber material characteristics. Some high-end models also support closed-loop monitoring to ensure vibration stability.

2. Transducer: The core component is a piezoelectric ceramic wafer, which uses the piezoelectric effect to convert high-frequency electrical signals into mechanical vibrations. Some industrial-grade equipment is equipped with an air-cooling structure to prevent overheating during prolonged operation and extend its service life.

3. Amplitude Modulator: This actuator serves a dual purpose of amplitude amplification and fixed support. Through a mechanical structure, it adjusts the transducer's vibration displacement to a range suitable for cutting requirements, while also providing vibration-free mounting points to ensure stable equipment operation.

4. Cutting Head: Custom-made from high-strength materials such as titanium alloy, it requires precise matching with the system frequency. Its geometry, length, and mass are optimized through computer modeling, and a custom blade shape can be designed according to the shape of the rubber product (straight cut, irregular cut).

Furthermore, in industrial scenarios, it can be combined with automated servo mechanisms to achieve multi-axis linkage control, adapting to the needs of high-volume, high-precision continuous cutting.

III. Five Core Advantages: Compared to traditional cutting tools (such as utility knives and mechanical cutting machines), ultrasonic rubber cutters demonstrate significant advantages in performance, efficiency, and cost, perfectly solving industry pain points:

1. High-Quality Cuts, Ready to Use Immediately: High-frequency vibration causes instantaneous fusion of molecules at the cut, resulting in a smooth, flat, burr-free, and deformation-free cut surface with excellent sealing. No subsequent grinding or correction processes are required, directly meeting the assembly requirements of end products and significantly improving yield. Data from an automotive parts manufacturer shows that after adopting ultrasonic cutting, the scrap rate of rubber seals decreased from 5% to below 1%.

2. Precise and Controllable, Widely Adaptable: The cutting process is almost pressure-free, avoiding material displacement. Whether it's thin, thick, hard, or soft rubber, high-precision cutting can be achieved. Complex irregular contours and intricate patterns can also be easily completed with excellent consistency.

3. Low energy consumption and durable, reducing costs and increasing efficiency: Cutting resistance is extremely low, reducing blade wear by more than 60% compared to traditional tools, and extending service life to three times that of traditional tools; no lubricant is required, energy consumption is only one-third of traditional cutting equipment, and downtime for tool changes is reduced, significantly lowering overall operating costs.

4. Environmentally friendly, clean, safe, and compliant: The cutting process produces no dust, smoke, or harmful waste, maintaining a clean workshop environment and meeting environmental production standards. It also avoids lubricant residue contamination of rubber products, making it particularly suitable for medical and food contact rubber processing.

5. Easy integration and automation: The system can easily interface with robotic arms and multi-axis motion platforms, enabling unmanned continuous cutting through programming, significantly improving production efficiency and adapting to the upgrade needs of modern production lines.

IV. Diverse Application Scenarios: Leveraging its superior cutting performance, ultrasonic rubber cutters have been widely applied in various fields such as automotive, medical, electronics, and aerospace, becoming standard equipment for high-end rubber product processing:

• Automotive Industry: Cutting engine gaskets, oil seals, O-rings, rubber hoses, suspension system bushings, etc., requiring precise sealing cuts to meet the stringent assembly standards of automotive parts.

• Medical Products: Processing medical silicone tubing, catheters, bottle stoppers, breathing masks, etc., requiring residue-free, high-cleanliness, and high-precision requirements to avoid material contamination caused by traditional cutting.

• Electronics and Consumer Electronics: Cutting waterproof sealing rings for mobile phones/watches, keyboard silicone gaskets, speaker diaphragms, cable sheaths, meeting the assembly needs of miniaturized, high-precision electronic components.

• Aerospace: Handling high-specification rubber sealing products resistant to extreme environments; cutting precision directly affects the sealing performance and safety of the equipment.

• Daily Consumer Goods: Processing high-end silicone kitchenware, gifts, toys, sporting goods, etc., meeting consumer demands for clean appearance and precise dimensions.

V. Key Usage Points and Future Trends

To ensure equipment performance and lifespan, the following precautions should be taken when using ultrasonic rubber cutters: Clean the cutter head regularly to avoid rubber residue affecting vibration performance; adjust the frequency, amplitude, and cutting speed according to the rubber material (hardness, thickness), for example, higher frequencies are suitable for soft rubber, while higher power is needed for hard rubber; ensure the cutter head frequency matches the system frequency to avoid resonance damaging components.

With the development of intelligent manufacturing and materials science, ultrasonic rubber cutters are upgrading towards greater precision, intelligence, and versatility. On the one hand, scenario-based customization is becoming a trend, with companies optimizing transducer designs to achieve precise adaptation to different materials, such as high-frequency solutions for soft rubber and high-power solutions for hard rubber; on the other hand, intelligent control technology is constantly iterating, using integrated sensors to monitor the cutting status in real time and automatically adjust parameters to further improve cutting consistency.

From solving the pain points of traditional processes to driving industry upgrades, ultrasonic rubber cutters have reconstructed the core logic of rubber processing through technological innovation. In today's high-end manufacturing environment with increasingly stringent requirements for precision, efficiency, and environmental protection, it is not only a cutting tool but also a crucial support for rubber product companies to enhance their core competitiveness, opening up broader space for industry development.