Introduction: The Art of Connection from Macro to Micro

In the field of microelectronics manufacturing, the precision of connection technology directly determines the performance and reliability of products. With the increasing miniaturization and integration of electronic components, traditional soldering techniques are gradually reaching their limits. Ultrasonic Immersion Tinning, as an innovative precision connection process, is redefining the boundaries of microelectronic packaging. It integrates the principles of ultrasonic energy and liquid metal wetting, achieving near-perfect metallurgical bonding at the microscale.

Core Technology: Synergistic Effect of Acoustic Energy and Liquid Metal

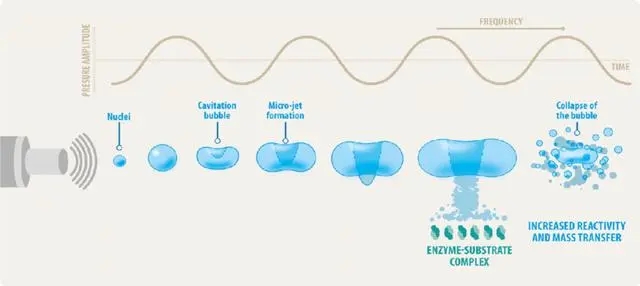

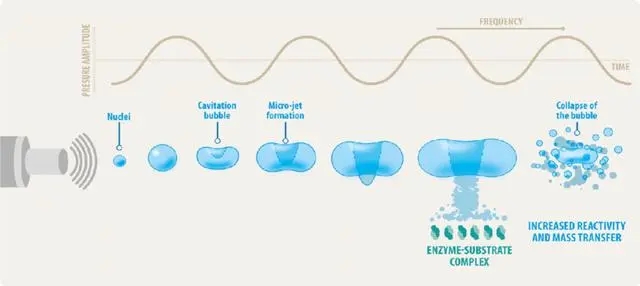

The principle of ultrasonic immersion tinning is based on the unique physical effects generated by high-frequency mechanical vibration (typically 20-200 kHz) in liquid solder:

Cavitation Effect: As ultrasonic waves propagate in molten solder, they generate periodic pressure changes, forming countless tiny vacuum bubbles that collapse instantaneously. This process generates local pressures of up to thousands of atmospheres and temperatures of hundreds of degrees Celsius, powerfully removing oxides and organic contaminants from the surface of substrates (such as chip leads and ceramic substrate pads), exposing an absolutely clean metal lattice.

Acoustic Flow Effect: Intense acoustic vibrations create directional micro-flow within the liquid solder. This micro-stirring accelerates heat and mass transfer, eliminates wetting dead zones, and ensures uniform solder spread across complex three-dimensional surfaces.

Interface Activation: Ultrasonic energy lowers the interfacial energy between the liquid solder and the solid substrate, enabling the solder to achieve exceptional flowability and wettability at lower temperatures (typically 30-50°C lower than conventional wave soldering).

Process System: Precise Engineering Integration

A complete ultrasonic tin-dipping system typically includes the following core modules:

Ultrasonic Generator and Transducer: Converts electrical energy into high-frequency mechanical vibration.

Dedicated Solder Bath: Contains molten solder and integrates the ultrasonic transmitter.

Precision Temperature Control System: Maintains the solder within the optimal process temperature window (typically 10-30°C lower than the melting point of conventional solder).

Inert Gas Protection Unit: Forms a nitrogen or argon protective layer above the solder bath to prevent secondary oxidation.

Automated transfer and positioning system: Ensures workpiece immersion at precise angles, speeds, and depths.

Technological advantages: Performance breakthroughs surpassing tradition

Fluoride-free soldering: The cavitation cleaning effect of ultrasound completely eliminates dependence on chemical fluxes, achieving true "zero residue" green manufacturing and avoiding the risks of flux corrosion and ion contamination, making it particularly suitable for high-reliability fields such as aerospace and medical applications.

Low-temperature bonding: The significantly reduced process temperature significantly reduces thermal damage to heat-sensitive components (such as MEMS sensors and organic substrates), lowering substrate warpage and internal stress.

Superior wetting quality: Forms a uniform, dense, and void-free intermetallic compound layer on material surfaces that are difficult to handle with traditional soldering (such as bare copper, nickel, gold plating, and even some ceramic and silicon surfaces), increasing shear strength by 20%-40%.

Handling complex geometries: For complex three-dimensional structures such as high-density pins, microvia arrays, and vertical sidewalls, the acoustic flow effect ensures perfect solder filling, solving the "shadowing effect" problem.

Application Scenarios: From Consumer Electronics to Cutting-Edge Technology

Power Electronics Packaging: Achieving void-free, highly reliable large-area tin plating on direct copper-clad (DBC) substrates of IGBTs and SiC modules.

Wafer-Level Packaging: Batch tinning of wafer bumps to prepare for subsequent flip-chip interconnection.

Microsystem Integration: Providing precision tin plating for the metallization structures of MEMS devices and microfluidic chips.

Aerospace and Defense: Flux-free sealing connections for high-density interconnects and microwave components.

New Energy Vehicles: Batch processing of precision connectors in Battery Management Systems (BMS).

Challenges and Future Development

Despite its significant advantages, this technology still faces challenges: high equipment costs; the need for fine-tuning process parameters (such as frequency, power, and immersion time) for different materials; and specific requirements for solder composition (often requiring customized low-melting-point, oxidation-resistant alloys).

Clear Future Development Trends:

Intelligentization: Integrating machine vision and AI algorithms to achieve real-time process monitoring and adaptive parameter adjustment.

Multiphysics Coupling: Exploring the synergy between ultrasound and other energies such as electric current and lasers to handle more specialized material combinations.

Materials Innovation: Developing dedicated lead-free solders, cryogenic solders, and even liquid metals suitable for ultrasonic environments.

Production Line Integration: Evolving towards more compact and modular designs, seamlessly integrating with SMT production lines.

Conclusion: Redefining the Boundaries of Connectivity

Ultrasonic immersion soldering technology is not merely an improvement in soldering methods, but also represents a paradigm shift in microelectronic connectivity from "macroscopic heat-dominated" to "microscopic energy-precise control." With its clean, precise, and low-temperature characteristics, it is becoming one of the key enabling technologies for overcoming the bottlenecks of heterogeneous integration and advanced packaging in the post-Moore's Law era. As application scenarios continue to expand and processes mature, this "silent art of immersion" will undoubtedly play an increasingly important role in building the microscopic world of future intelligent devices.