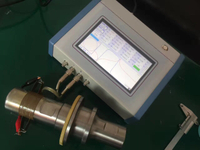

20Khz Ultrasonic Assisted Machining for Hard Ceramics Or Soft Optical Materials

Introduction

Ultrasonic machining is suitable for processing hard and brittle materials, and can process complex three-dimensional cavities. Traditional ultrasonic machining requires tools that are opposite to the cavities and convexities of the machined cavity. Therefore, the tool is very complicated to manufacture, and the tool has high processing cost and long cycle. Problems such as serious tool wear during processing seriously affect the accuracy and efficiency of processing. Ultrasonic milling is an emerging ultrasonic machining process. It uses simple shape tools, based on the layered manufacturing idea in rapid prototyping, and uses layered removal to process hard and brittle materials. It has simple tool making and small macro force between tools and workpieces. The tool loss can be compensated, and the processing of complex three-dimensional contours can be realized. It is an ultrasonic processing technology with development prospects.

Rotary ultrasonic machining technology is one of the effective methods for processing engineering ceramics, but there are problems such as complicated tool making and serious tool wear during processing, which seriously limits its application in the processing of complex cavity ceramic parts. Rotating ultrasonic forming with a simple tool like a milling cutter is a viable method for solving complex cavity machining in ultrasonic waves in recent years.

Parameters of Ultrasonic Machining:

The ultrasonic vibration machining method is an efficient cutting technique for difficult-tomachine materials. It is found that the USM mechanism is influenced by these important parameters.

Amplitude of tool oscillation(a0)

Frequency of tool oscillation(f)

Tool material

Type of abrasive

Grain size or grit size of the abrasives – d0

Feed force - F

Contact area of the tool – A

Volume concentration of abrasive in water slurry – C

Ratio of workpiece hardness to tool hardness; λ=σw/σt

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

Features:

Simple installation

Improve the surface integrity of the material being processed for true cold cutting

Reduce the cutting resistance during tool processing and reduce the residual stress on the surface of the machined material

High-speed machine tool processing can be used to improve machining efficiency in low-speed machine applications

Customized JT, BT, HSK, straight shank and other specifications according to the user's machine tool spindle

Suitable for hard and brittle materials, such as: glass, ceramic lamps are more difficult to process materials.

English

English