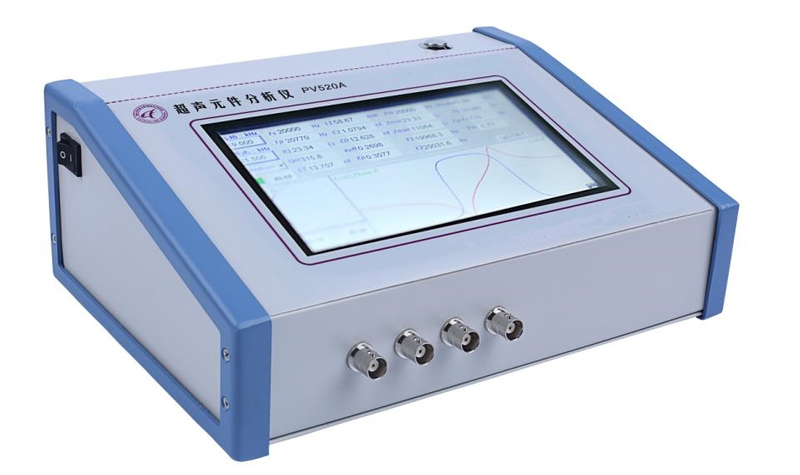

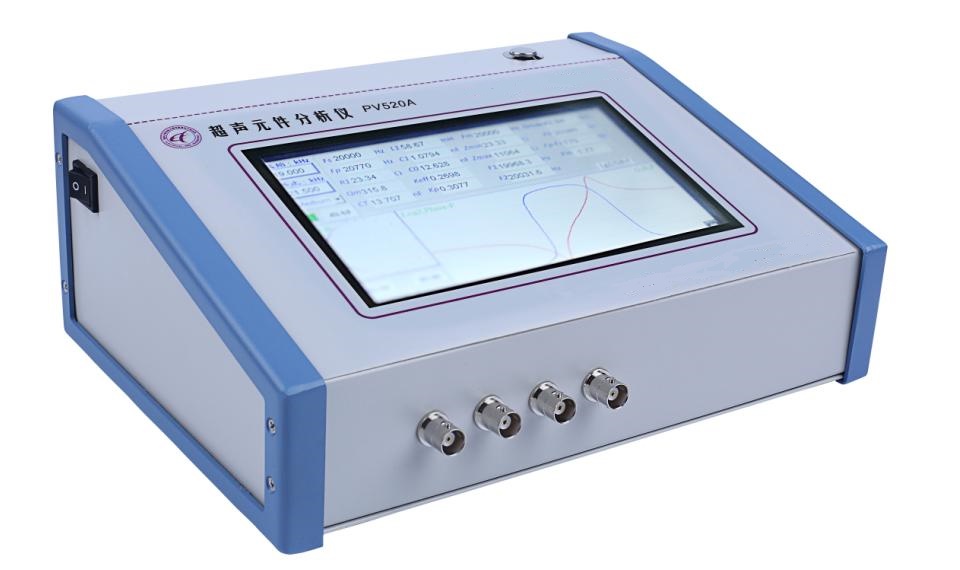

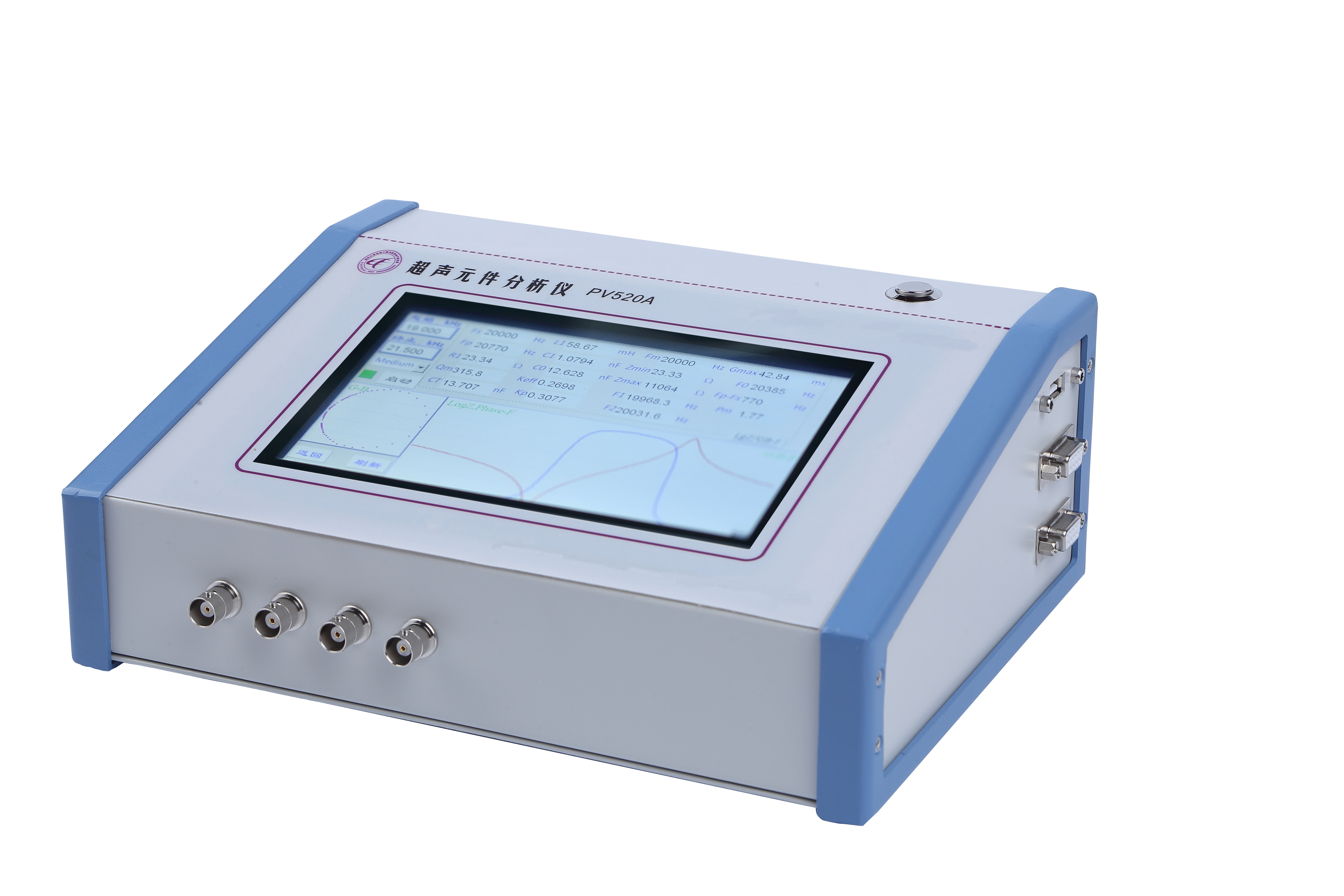

How to balance an ultrasonic transducer by ultrasonic impedence analyzer ?

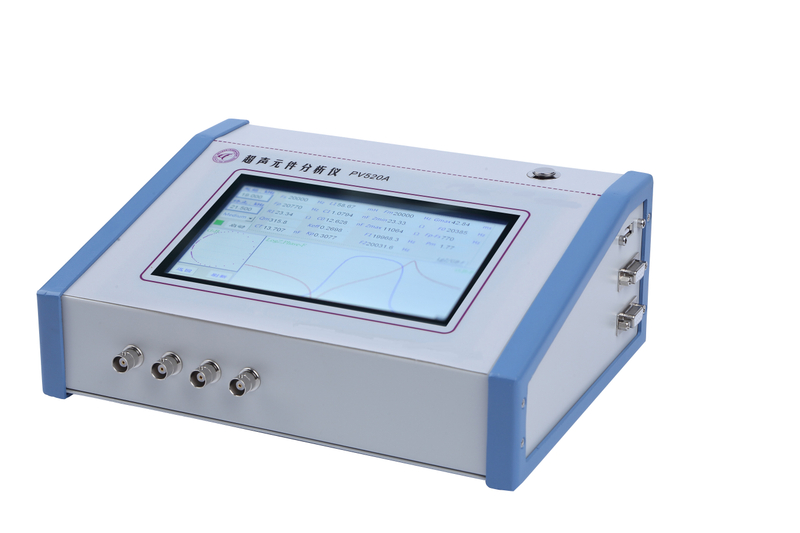

Piezoelectric ceramic ultrasonic transducer is the core component of ultrasonic products. The quality of the quality star directly affects the performance of the entire ultrasonic equipment. Our transducers are strictly tested by the piezoelectric ceramic evaluation system. The impedance analyzer can be used to evaluate piezoelectric ceramic sheets, piezoelectric transducers, and entire vibration systems (transducers + horns, molds) and other devices. The performance of the device is good or bad. Analysis of ultrasonic device equipment with an impedance analyzer, the most important parameters are as follows:

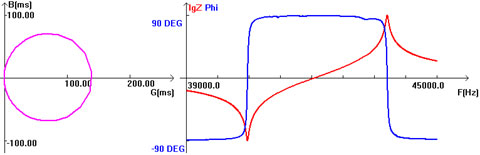

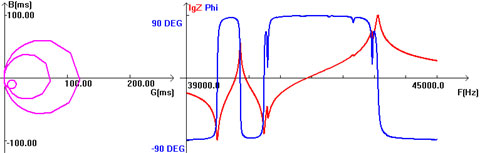

1. Fs: The mechanical resonant frequency, ie the operating requency of the vibration system, should be as close to the expected value as possible in the design.

This is the most important paramter as I think in the matching work.

For a cleaning machine, the higher the resonant frequency consistency of the vibrator, the better.

For plastic welders or ultrasonic machining, if the horn or ultrasonic mold is not designed properly, the resonant frequency of the vibrator will deviate from the operating point.

2. Gmax: Conductance at resonance, the conductance of the vibration system when operating, which is the reciprocal of the dynamic resistance. The bigger the better under the same support conditions, Gmax = 1. /R1. Generally for cleaning or welding vibrators, generally between 50ms ~ 500ms. If it is too small, in general, the vibrator or vibration system will work.

There are problems such as circuit mismatch or low conversion efficiency and short life of the vibrator.

3. C0: Capacitance of the static branch in the equivalent circuit of the piezoelectric device, C0=CT-C1 (where: CT is the free capacitance at 1 kHz, and C1 is the equivalent of the piezoelectric device.

The capacitor star of the dynamic branch in the road). When using, balance C0 with inductance.

In the circuit design of the cleaning machine or ultrasonic processing machine, correctly balancing C0 can increase the power factor of the ultrasonic power supply. There are two methods for using the inductance balance.

Parallel tuning and series tuning.

4. Qm: mechanical quality factor, determined by the conductance curve method, Qm=Fs/ (F2 - F1), the higher the Qm, the better, because the higher the Qm, the higher the vibrator efficiency;

Qm must match the power supply. When the Qm value is too high, the power supply cannot be matched.

For cleaning the vibrator, the higher the Qm value, the better. In general, the Qm of the cleaning vibrator should reach 500 or more. If it is too low, the vibrator efficiency is low.

For the ultrasonic welding machine, the Qm value of the vibrator itself is generally around 500, and after adding the horn, it generally reaches about 1000, with the horn it can reach 1500~3000. If it is too low, the vibration efficiency is low, but it should not be too high, because the higher the Qm, the narrower the working bandwidth, the hard power supply is difficult to match, and the power supply is difficult.

To work at the resonant frequency point, the device does not work.

5.F2, F1: the half-power point frequency of the vibrator. For the entire vibration system (including the horn and the mold) for ultrasonic machining, F2-F1 is greater than 10 Hz, otherwise the frequency band is too narrow, the power supply is difficult to operate at the resonance frequency point, and the device cannot work.

F2 - F1 is directly related to the Qm value, Qm = Fs / (F2- F1).

6. Fp: anti-resonance frequency, the resonant frequency of the parallel branch of the piezoelectric vibrator. At this frequency, the impedance of the piezoelectric vibrator is the largest.

7. Zmax: anti-resonant impedance, under normal circumstances, - the anti-resonant impedance of a transducer is above several tens of kilohms, if the anti-resonance impedance is relatively low, the life of the vibrator is relatively short.

8. CT: Free capacitance, the capacitance value of the piezoelectric device at 1 kHz. This value is consistent with the value measured by the digital capacitance meter. This value is subtracted from the dynamic capacitor C1.

This is also an important paramter in the matching work.

The real static capacitance C0 can be obtained. C0 needs to be balanced by an external inductor. C1 participates in the star conversion when the system is working, and does not have to be balanced.

9. R1: Dynamic resistance, the resistance of the series connection of the piezoelectric vibrators, the smaller the better under the same support conditions. For cleaning or welding the vibrator, if R1 is too large, there is a problem with the vibrator.

It is a reference parameter to check the transducer quality.

10. Keff: effective electromechanical coupling coefficient, - in general, the higher the Keff, the higher the conversion efficiency