Application of The Ultrasonic Sewing Machines

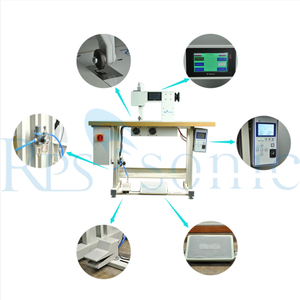

Ultrasonic sewing machines achieve needle-free, wireless welding by generating heat through friction between thermoplastic material molecules via high-frequency vibration. They offer core advantages such as seamless waterproofing, no pinholes, sealed edges to prevent detachment, high efficiency, and environmental friendliness with no chemical residues. They are widely used in various fields including medical, textile and apparel, automotive interiors, home textiles, hygiene products, and outdoor industrial applications. Specific application scenarios are as follows:

Medical and Hygiene Protection Field

1. Disposable Medical Consumables: Surgical gowns, surgical caps, shoe covers, sterile drapes, disinfection packs, etc. Seamless welding prevents bacterial penetration, and the absence of pinholes ensures a sterile environment, meeting the high cleanliness requirements of medical settings.

2. Protective Equipment Manufacturing: Welding of multi-layer meltblown fabric/non-woven fabric for N95/KN95 masks and face shields without damaging the filter layer, while achieving efficient edge sealing and improving protective performance.

3. Medical Dressings and Packaging Materials: Sealed packaging of wound dressings and sterile gauze; thermoplastic connections for medical accessories such as infusion bags and catheters, ensuring biocompatibility and airtightness.

Textile, Apparel, and Underwear Sector

1. Seamless Apparel Processing: Welding of side seams, shoulder straps, and waistbands in underwear, sportswear, swimwear, and diving suits eliminates the rough feel of traditional stitching, improving wearing comfort and fit.

2. Lace and Decorative Techniques: Lace and openwork patterns on women's wear, evening gowns, and wedding dresses are pressed together without hemming, resulting in delicate patterns and smooth edges, facilitating design innovation.

3. Functional Apparel Manufacturing: Welding of waterproof seam strips on windbreakers and outdoor jackets achieves seamless waterproofing while avoiding leakage problems caused by traditional stitching.

Automotive Interiors and New Energy Sector

1. Automotive Interior Assembly: Splicing and fixing of seat fabrics, door panels, headliner linings, carpets, etc. Welded seams are vibration-resistant and durable, replacing glue and clips, reducing VOC emissions.

2. Sound Insulation and Safety Components: Sealing and connecting automotive sound insulation cotton, heat insulation pads, and airbags. The pinhole-free design improves sound insulation and protection, adapting to complex automotive operating conditions.

3. Battery and Wiring Harness Related: Welding of insulating film for new energy vehicle battery packs and protective sleeves for wiring harnesses to achieve sealing and moisture protection, ensuring electrical safety and stability.

Home Textiles and Furniture Sector

1. Bedding Processing: Lace pressing and splicing of sheets, bedspreads, pillowcases, duvet covers, etc. Pinhole-free design enhances aesthetics and durability; quick-change pattern rollers allow for diverse designs.

2. Home Decor Applications: Edge sealing and decoration of curtains, sofa covers, cushions, tablecloths, etc. Seamless craftsmanship enhances texture while preventing fraying and facilitating cleaning.

3. Soft Furnishings and Outdoor Furniture: Waterproof welding of awnings, tents, outdoor chair covers, etc., adaptable to humid outdoor environments, extending service life.

Hygiene Products and Daily Necessities Sector

1. Disposable Hygiene Products: Welding of the top and bottom layers of diapers, sanitary napkins, wet wipes, etc., to achieve sealing and leak-proof protection, eliminating chemical residues and ensuring safe use.

2. Eco-friendly Packaging Manufacturing: Sealing and handle welding for non-woven bags, shopping bags, and garbage bags, replacing needles and glue, improving production efficiency, and aligning with green environmental trends.

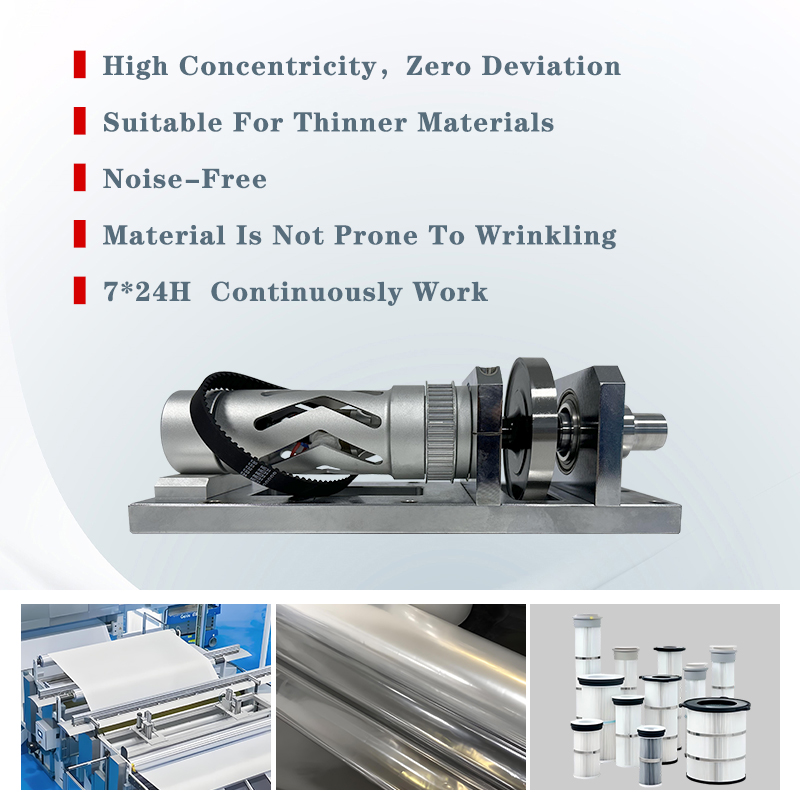

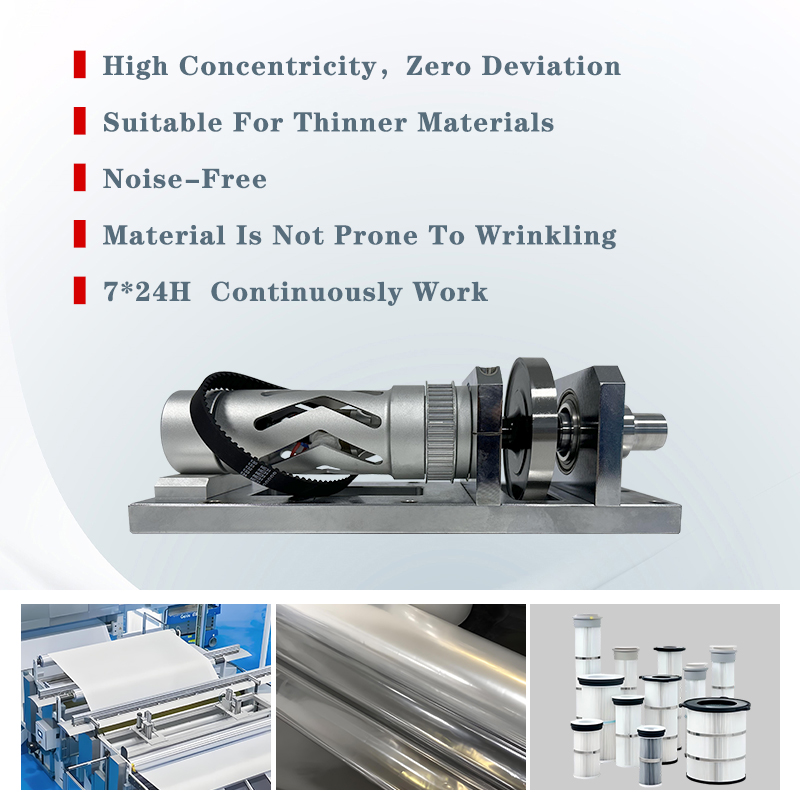

3. Filter Material Processing: Edge sealing and molding of air purifier filters, aquarium filter cotton, etc., preventing filter material from falling off, improving filtration efficiency and lifespan.

Aerospace and Special Industrial Fields

1. Aviation Interior Components: Welding of aircraft seat fabrics, cabin linings, sound insulation materials, etc., resulting in lightweight and high-strength welds, meeting the stringent weight and safety requirements of aviation.

2. Special Protective Equipment: Interlayer bonding of bulletproof vests, chemical protective suits, fire-fighting suits, etc., with a pinhole-free design to enhance protective performance while improving the overall integrity and durability of the fabric.

3. Industrial Filter Media and Seals: Welding of industrial dust collector filter bags, pipe gaskets, etc., achieving high-temperature and corrosion-resistant sealing connections, suitable for harsh industrial environments.