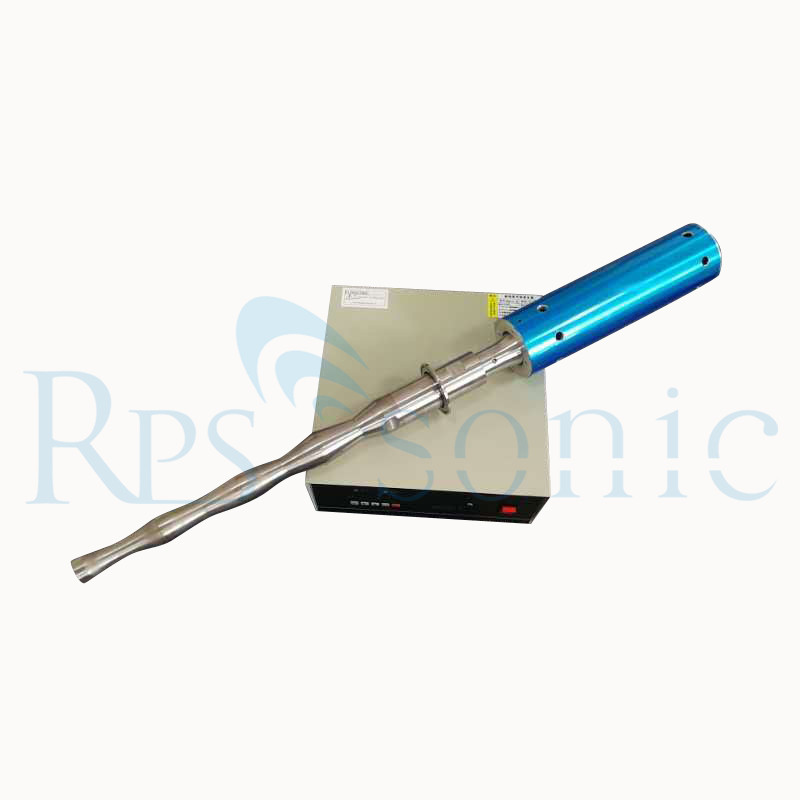

20Khz Ultrasonic Homogenizer for Wine homogenizer

What is an Ultrasonic Homogenizer & how can we use it in cocktails?

The premise is simple - An Ultrasonic homogenizer is a piece of laboratory or industrial equipment used for the homogenization of various types of material, such as tissue, plant, food, soil, and many others using ultrasound. The question arises is why is this useful in cocktails & how can we actually use it effectively in our bar programs. Essentially the only piece of equipment that is marketed towards cocktail bars is the Polysciecne Sonicprep we linked to above.

Description:

In any low-to medium-viscosity liquid, the probe tip releases rapid, high-frequency ultrasonic vibration waves that expand and collapse microscopic bubbles at 20,000 cycle per second. The process takes just 2-3 minutes and generates only insignificant amounts of heat, preserving vivid colors, aromas and nutrients, while producing rounder and smoother overall flavors.

Stable Emulsions: create a very fine suspension of liquids that don't mix (vinaigrette) without using an emulsifying agent.

Aging calvados with wood chips in less than 2 minutes with a flavor effect that would usually take 2 years.

Degas and homogenize wine: wine treated for 1-2 minutes will appear with a much fuller and rounder mouth feel.

Infusions and extractions: volatile aromas of fresh herbs or spices can be quickly infused into a liquid, such as a cocktail.

Intensifying fruit or vegetable pulp for sauces and purée by cell disruption

Tenderizing and marinating meat

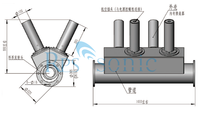

Parameter

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

In recent years, the oenological industry has undergone a great evolution, introducing innovative technologies in the wine-making industry to optimize and make processes profitable, as well as to achieve higher product quality but also increase its diversification. In any case, acceptance by the consumer is essential, being the aroma one of the factors that most influence the sensory evaluation of wine.

The final aroma of the wine involves a high number of volatile compounds which are formed by diverse biological, biochemical and technological processes, such as grape metabolism, pre-fermentation processes, metabolism of microorganisms (alcoholic and malolactic fermentation) and chemical and enzymatic reactions that occur during the aging of wine.

Grape-derived compounds (primary or varietal aroma) play an important role in the character of a wine, as they usually present pleasant aromas related to the grape variety. Many of these compounds are found in the grape skin, in many cases in the form of precursors (glycosides, fatty acids, phenolic acids, amino acids, S-cysteine conjugates) that release odoriferous molecules through enzymatic or chemical hydrolysis