Ultrasonic Food Cutting Blade Cutter for Cake And Bread Cutting

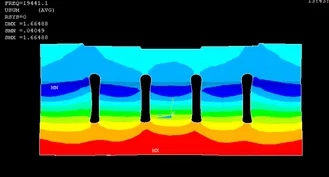

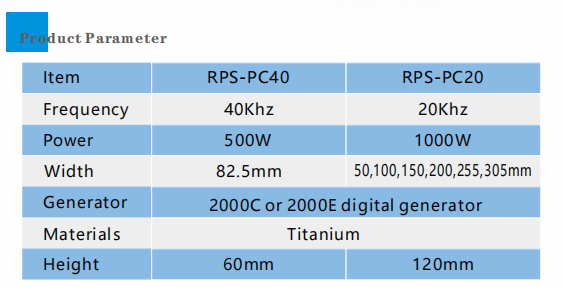

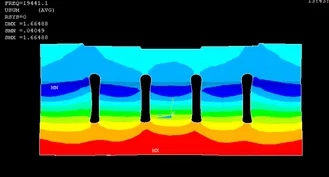

The principle of the ultrasonic food cutter is based on the use of high-frequency vibrations generated by an ultrasonic transducer. These vibrations are typically in the range of 20 kHz to 40 kHz and are transmitted to Ultrasonic Blades, also known as a horn, which amplifies the vibrations and focuses them onto the material being cut.

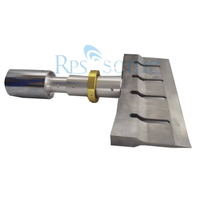

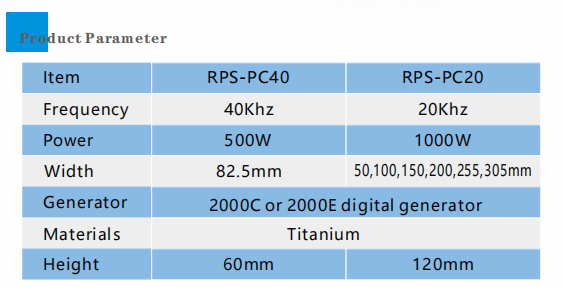

305mm blade

"Ultrasonic food cutting knife As the blade vibrates, it creates a series of rapid, low-amplitude movements that cause the material to be cut. The ultrasonic waves create a localized heat effect at the cutting point, which softens and melts the material. This, in turn, reduces the cutting force required, resulting in a clean and precise cut.

Overall, the principle of the ultrasonic food cutter is to use high-frequency vibrations to soften and melt the material being cut, reducing the cutting force required and resulting in a clean and precise cut.

Application

Ultrasonic Blade Cutting machine is suit for cutting various frozen foods,viscous foods,suck like, cheese cake, nougat, wafer biscuits, frozen cheese. The high frequency vibration of the ultrasonic can effectively reduce the cutting resistance, and make the cutting surface smooth and beautiful.

Also applied in rubber cutting , Rubber goods have high toughness, ultrasonic cutting knife can greatly reduceresistance and increase cutting speed.

♦ Bakery and snack foods,

♦ Candy and confectionery cheese/Fish/Prepared meat/Vegetable/Health Bars;

♦ Chocolates, sandwich and wrap cutting;

♦ Dry fruit;

♦ Poultry;

♦ Potted;

♦ Processed meat;

♦ Ground meat;

It is often used for food cutting, which is clean and hygienic, with neat and beautiful cutting surfaces, and can also avoid unnecessary waste.

Advantage

● 1. Non-Pollution, with no smoke, odor, or flying debris produced during cutting, eliminating dust and air pollution during cutting;

● 2. Reduce waste, as it does not crush or damage your products during cutting, reducing waste;

●3. Ensure neat, smooth, and non-deformed incisions, enhancing the appearance and value of the product. (Providing a good cutting surface);

●4. Reduce stop time, as the blades do not need to be cleaned frequently when cutting sticky products;

●5. The blade is made of durable titanium material;

●6. Reduce cutting resistance, cutting fastert.

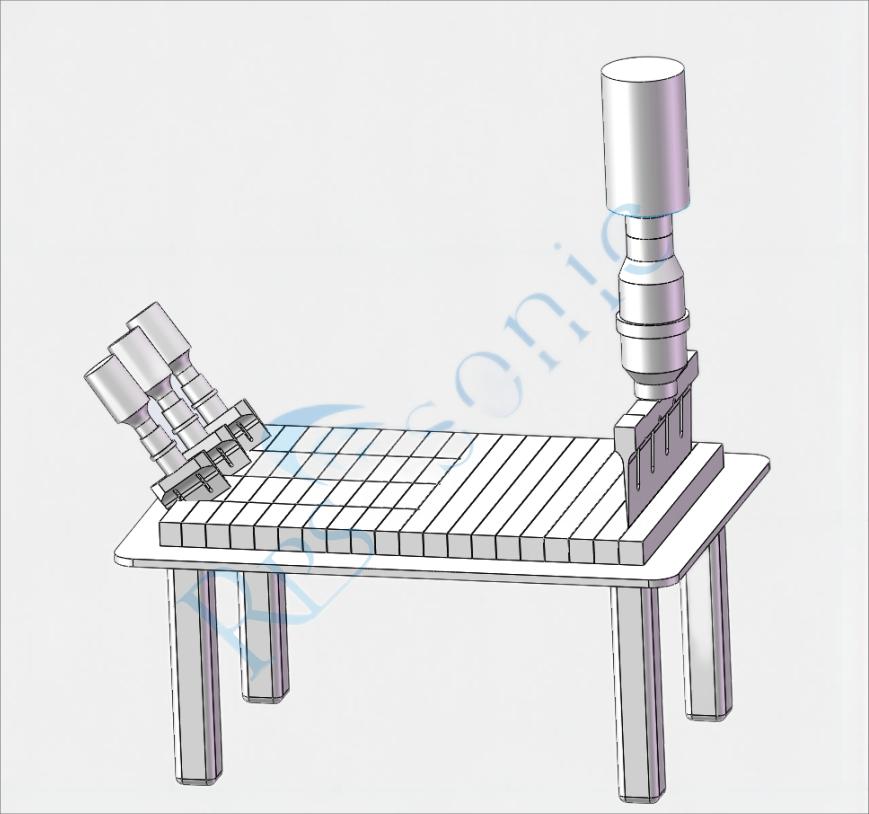

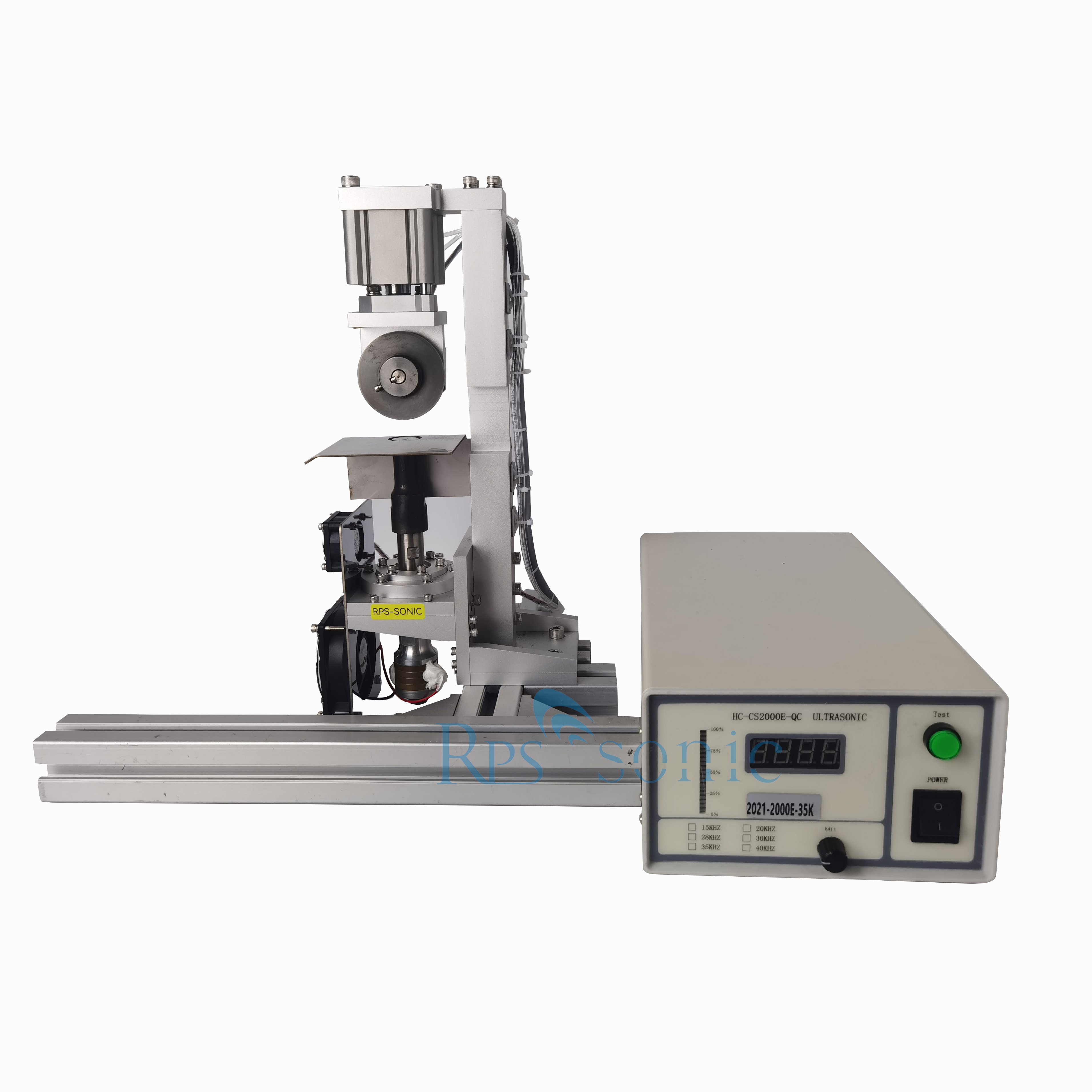

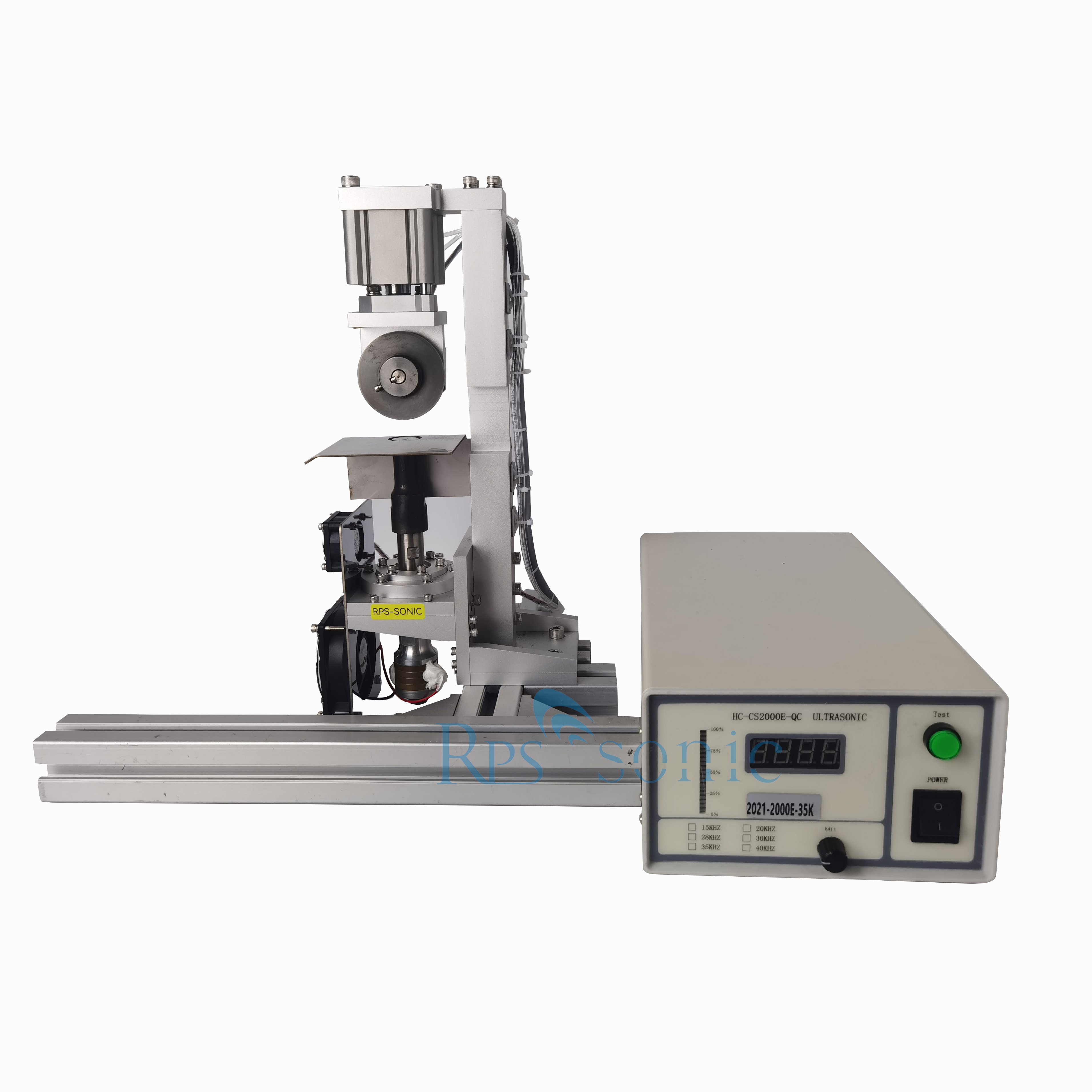

automatic ultrasonic cutting machine

ultrasonic cutting knife with generator

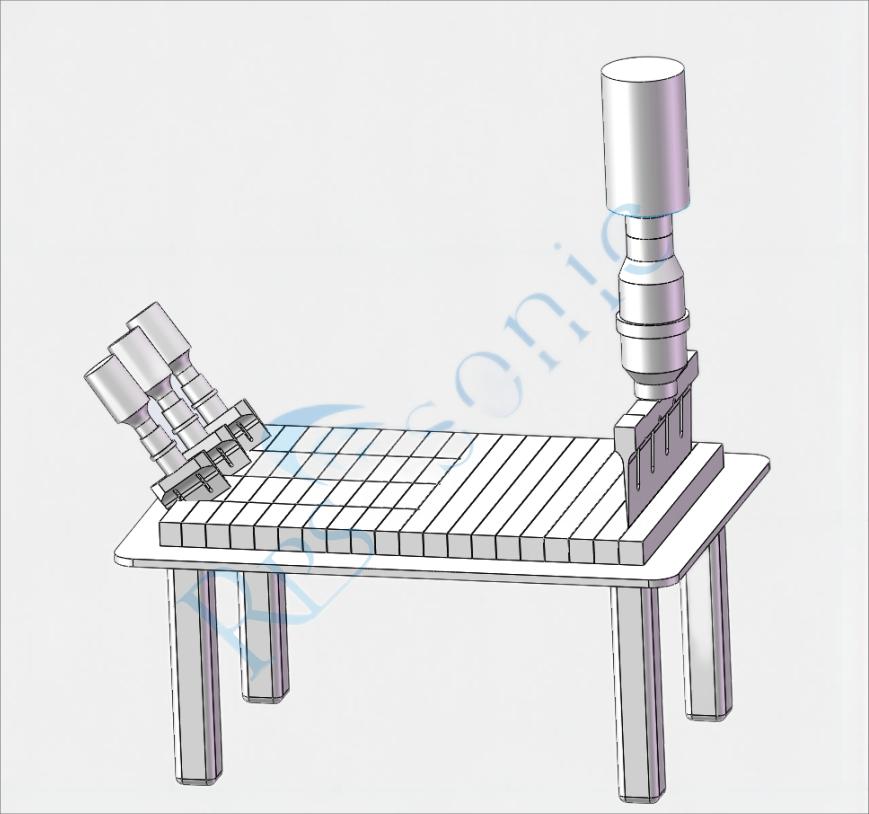

desktype ultrasonic cutting system

Ultrasonic cutting for trimming |

Ultrasonic slicer for fabric |

Ultrasonc slicer |

Famous customers