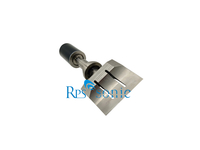

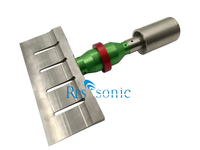

20khz 305mm Cutting Blades Ultrasonic Cutting Blades Titanium Alloy Cutting Blades

What's the principle of ultrasonic cutting?

The principle of an ultrasonic cutter is completely different from conventional one. It uses the energy of ultrasonic to melt the material to be cut. Therefore, the ultrasonic cutting does not require a sharp cutting edge, nor does it require a large pressure, and does not cause any chipping or breakage. At the same time, since the cutting blade is subjected to ultrasonic vibration, the frictional resistance is particularly small, and the material to be cut is not easily adhered to the blade. This is particularly effective for cutting viscous and elastic materials, frozen materials such as food, rubber, etc., or objects that are inconvenient to apply pressure.

Ultrasonic knife blade vibrating at an ultrasonic frequency can easily slice through the material to be cut quickly and precisely without leaving behind any residue in the form of particles. Ultrasound has been used for years for cutting finished products. The swinging, cold cutting sonotrode reduces resistance in the cutting process and even cleans itself off residue when used with baked goods, energy bars, cheese, pizza, etc.This highly productive ultrasonic food cutting equipment can cut the type of food sheet, round, rectangular, not only cut the product size adjustable, and the cutting type can be easily accessed through the touch screen control interface. Food ultrasonic cutting machine for food slicing separation is to ensure that the exact size of the cut to achieve the minimum waste to achieve the maximum benefits, and this equipment will be able to meet the above needs. The body of the machine is made from stainless steel. Security devices provide the machine off if the doors are open. The touch panel allows the operator to maintain the formulation, production parameters, simplifying machine management.

We can combine automatic ultrasonic cake cutter with robotic technology is designed for continuous supplied product to be cut on the belt, in a box, or in a foil container. It is ideal for sticky, difficult to cut products. The machine can cut round, square, rectangles or triangles and is designed to employ ultrasonic cutting systems, servo driven conveyor, and is “wash down” compatible for ease of cleaning and sanitation. The upstream process can be automated by the addition of an auto load conveyor and the downstream process can be automated with an exit conveyor. Beautifully shaped products, less cutting waste, safe cleaning and more profit. Experience it all with the COMPACT ULTRASONIC SLICER! RPS-SONIC ultrasonic cutting machine is equipped with an ultrasonic system with high-quality titanium blades that is specially developed by BAKON to accomplish the best cutting results.

Parameter

| Machine | Ultrasonic cutting blades |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting witdth | 50mm,100mm,150mm,200mm,255mm,305mm. |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG

|

Advantages

1, easy to apply to automated production

2, the cutting surface smooth.

3, fast, high efficiency, no pollution.

4. Ultrasonic cutting machine adopts hand-held cutting design, which can replace different specifications of cutting knife mold, which is easy to use;

5, with high frequency vibration of 40KHZ or 20KHZ, this low friction makes the cutting knife cut food smoothly, making the food cutting surface clean, beautiful and not deformed;

6, cutting blades from 50mm to 350mm available, customizable.

Applications:

Cake,Sandwich, biscuit, wafer, nougat

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars