1. What’s the warranty of your ultrasonic cutter?

Our warranty is one year , but we can supply you Components free even out of warranty.

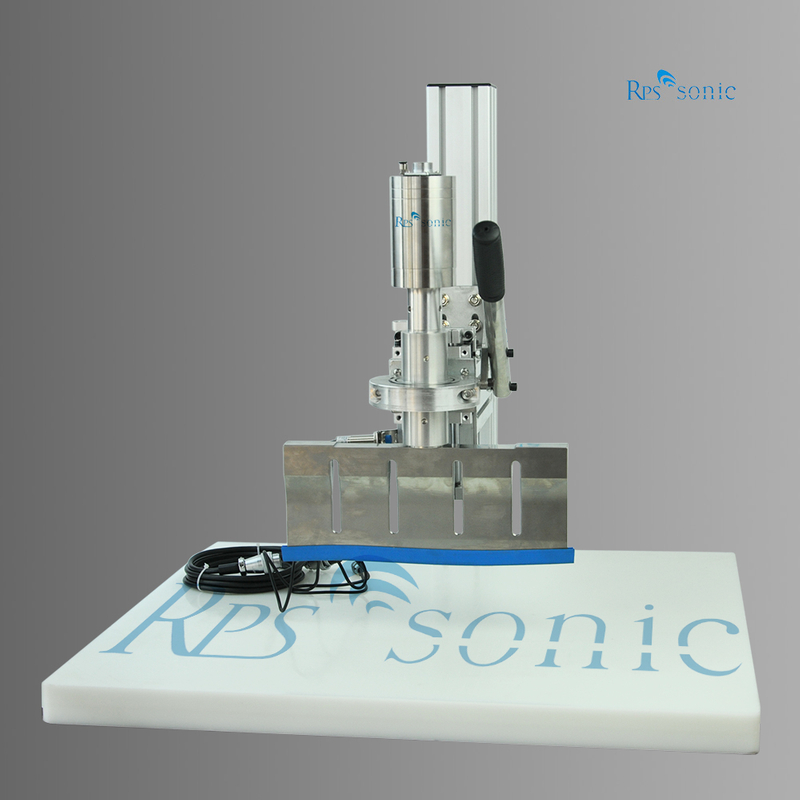

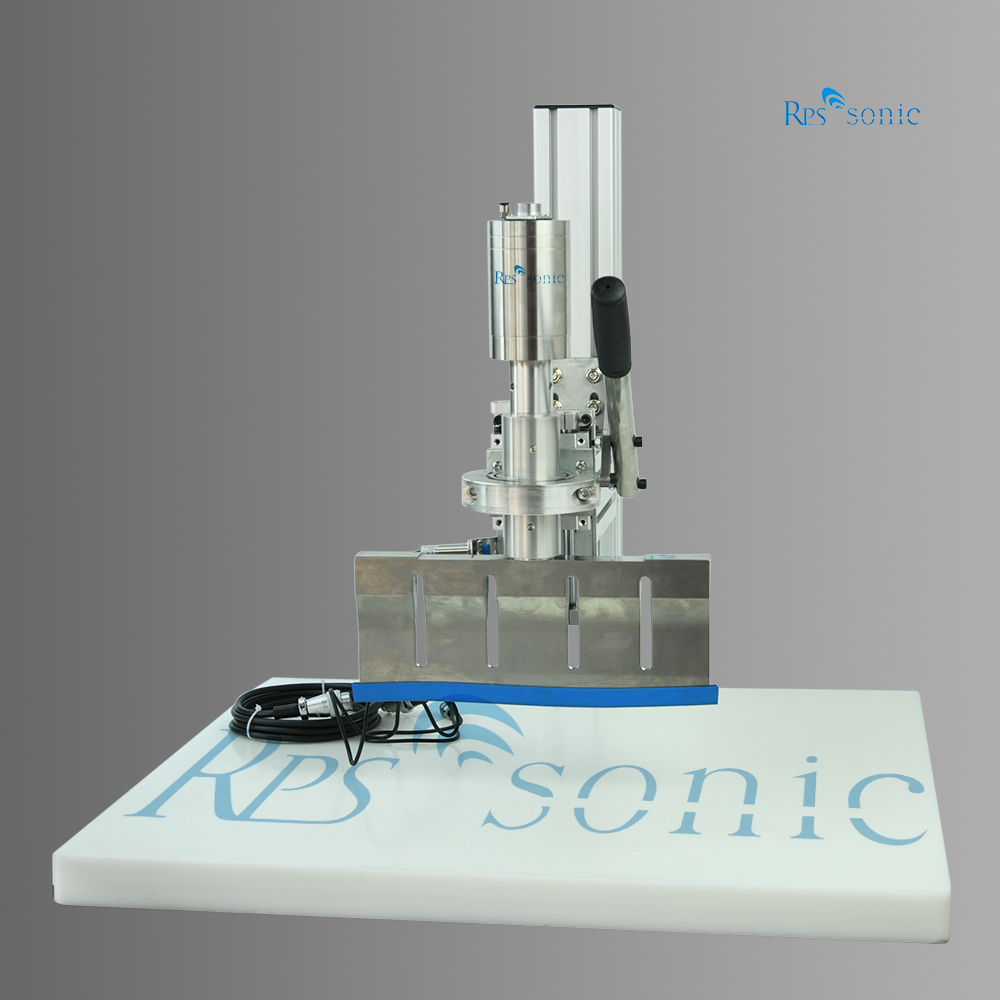

2. What’s frequency ultrasonic cutter you supply?

We can supply generatorr from 20~40khz depending on your requirements or application.

4. What’s the using life of your ultrasonic cutting equipment?

Under correct working environment, our ultrasonic cutter can work 3~5 years

5. Does your products exported before?

Yes, our Generator exported to USA,south America, EUROPE, Middle East, and Russia for many years.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

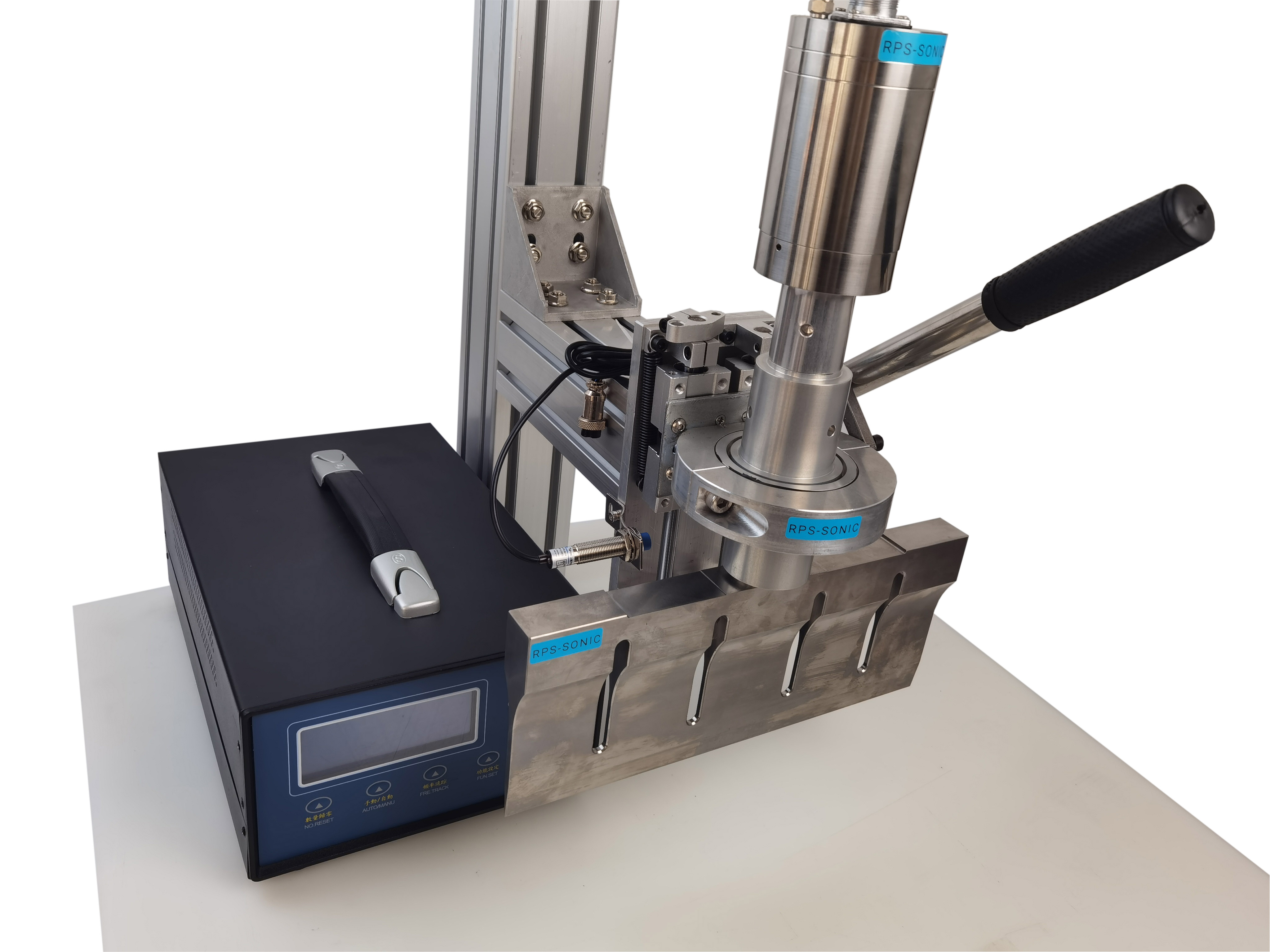

8. How to customize blades ?

you can tell us your dimension requirements, we will customize depending on your requirements.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.