Ultrasonic Impact Gun UIT Machine for Compressive Residual Stress

Product description

Designed to significantly improve and extend the life cycle of industry assets, Ultrasonic Impact Technology (UIT) is instrumental in mitigating tensile stress in heat-effected zones in the mining sector

Ultrasonic Impact Technology treatment is an electromechanical process where ultrasonic energy is converted into mechanical energy.

When UIT is applied to metals and fabricated structures, the process imparts residual compressive stresses, mitigating harmful tensile stress along with modifying grain structure. It can be applied manually or automated depending on the environment which the technology is required to operate in.

The UIT system is an electromechanical process where ultrasonic energy is converted into mechanical energy. When applied to metal fabricated structures, UIT imparts compressive residual stress, mitigates harmful, flexible stress, modules weld toe geometry, and improves grain structure.

UIT delivers an alternative to other methods of peening to modify weld toe geometry and impart beneficial compressive residual stress. Upon application of UIT to the weld toe, the weld toe geometry is modified creating a fatigue friendly geometry.

Compressive residual stress is imparted into the heat affective zone (HAZ) improving grain structure and strength.

A number of research projects indicates that UIT method can increase the fatigue strength of steel welding joint by 60~180%, prolong fatigue life by 10~135 times. It also leads Ti Al welding joint to increase fatigue strength by 26~48% and fatigue life by 5~54 times.

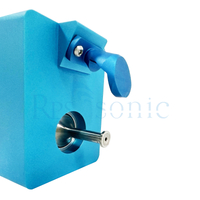

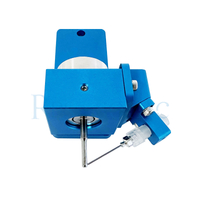

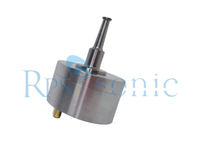

RPS-SONIC Ultrasonic impact treatment machine is composed of ultrasonic transducer with cover, booster, horn, needle and generator.

Parameter:

| Item | RPS-IM20 |

|

|

| Frequency | 20Khz |

|

|

| Power | 1000W |

|

|

| | Digital generator 2000C or 2000B |

| Materials | Customized from 2mm to 5mm, titanium or aluminum or DC53 |

Efficacy:

1. Cause residual stress of pulling in the metal welding line surface layer changed into compressive stress. Significantly increase the fatigue life of metal structure. Ultrasonic aging improve 80%-100%.

2. Change the grain layer on metal surface into plastic deformation layer to improve strength and hardness of metal surface layer significantly.

3. Improve the weld toe geometric, reduce the stress focus.

4. Change weld toe stress field, reduce welding deformation obviously, and improve size stability of work piece.

Main advantage:

1. High power, high impact effect

2. High reliability, long using life

3. Light weight, portable, easy to operate

4. Excellent designation, wide use scope

5. Distinctly save energy, reduce charge

Application:

The industries have strict requirement on welding stability and strength. Such as bridge, electric power, ship building, pressure vessel, steel structure and other industry's metal welding.

Advantages of ultrasonic impact surface finishing

-Increase the surface finish quality-Increase the surface hardness.

-Improve the fatigue resistance and corrosion resistance.

-Decrease the initial damage of workpiece.

-Remove spot pits on the metal surface.

-Special purpose metalworking machines, chipless