Soft, Low-velocity Spray Ultrasonic atomizer 50Khz

Introduction:

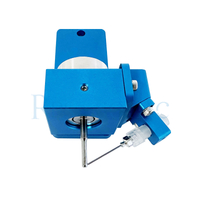

ultrasonic spraying nozzles are light weight flow through design for introducing liquids at the back of the nozzle. With nozzle materials made from titanium, stainless steel and fluoropolymer, many different solutions can be made into a mist. Sonaer ultrasonic atomizers are easy to clean, maintain, reliable and have no moving parts to wear out. Without the use of air pressure, varying viscosity liquids are pumped through the center of the nozzle, and is atomized. The droplets are then used in processes either for coating, burning, moisturizing, fabricating nano tubes or other applications that require droplets made from liquids. Sonaer's ultrasonic atomizer designs are anti-flashing, preventing liquid from reversing back into the probe from ultrasonic standing wave vibration and bursting out from the tip causing irregular droplets to be formed. Smaller and more uniform droplet size is a benefit from this type of liquid atomization.

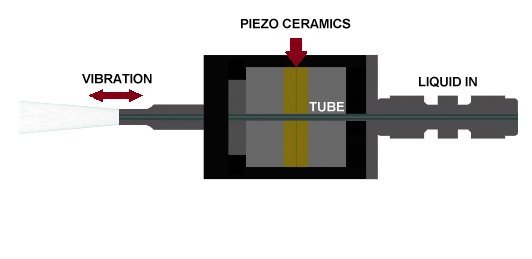

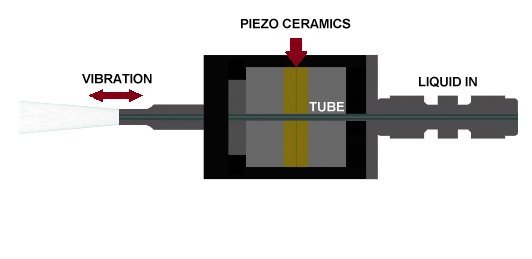

In the center of the probe are piezo ceramics which convert the electrical signal to mechanical vibration. This vibration is amplified by the step that forms the tip of the probe, and is reflected back towards the ceramics , mixes with outgoing waves, creating standing waves. These standing waves cause a pumping action that sucks liquid towards the center of the probe.

With the Sonaer atomizer probe design, liquid will spray continuously, will not flow back into the probe from these standing waves, creating a sudden spurt of liquid, called "flashing". The spray from these atomizers will be smooth and controllable with very little overspray. Spray thickness is nano - microns which is all user adjustable. The thickness is set by the delivery flow rate or shot, power level of the nozzle, liquid characteristics and the time the substrate is exposed to the liquid. For heavy coatings use low frequency probes, for ultra thin coatings typically use the higher frequency nozzles.

Parameter:

| Item | Parameter |

| Frequency | 50Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~20ml/min |

| Spray width | 2~200mm |

| Solution utilization | above 98% |

Advance:

Material Savings, and Precise Control:

In coating applications, the unpresssurized, low-velocity spray significantly reduces the amount of overspray since the drops tend to settle on the substrate,rather than bounce off it. This translates into substantial material savings and reduction in emissions into the environment.

The spray can be controlled and shaped precisely by entraining the slowmoving spray in an ancillary air stream. Spray patterns from as small as 0.070 inches wide to as much as 1-2 feet wide can be generated using specialized

types of spray-shaping equipment.