High Frequency Ultrasonic Atomization Nozzle for antimicrobial coatings

Introduction:

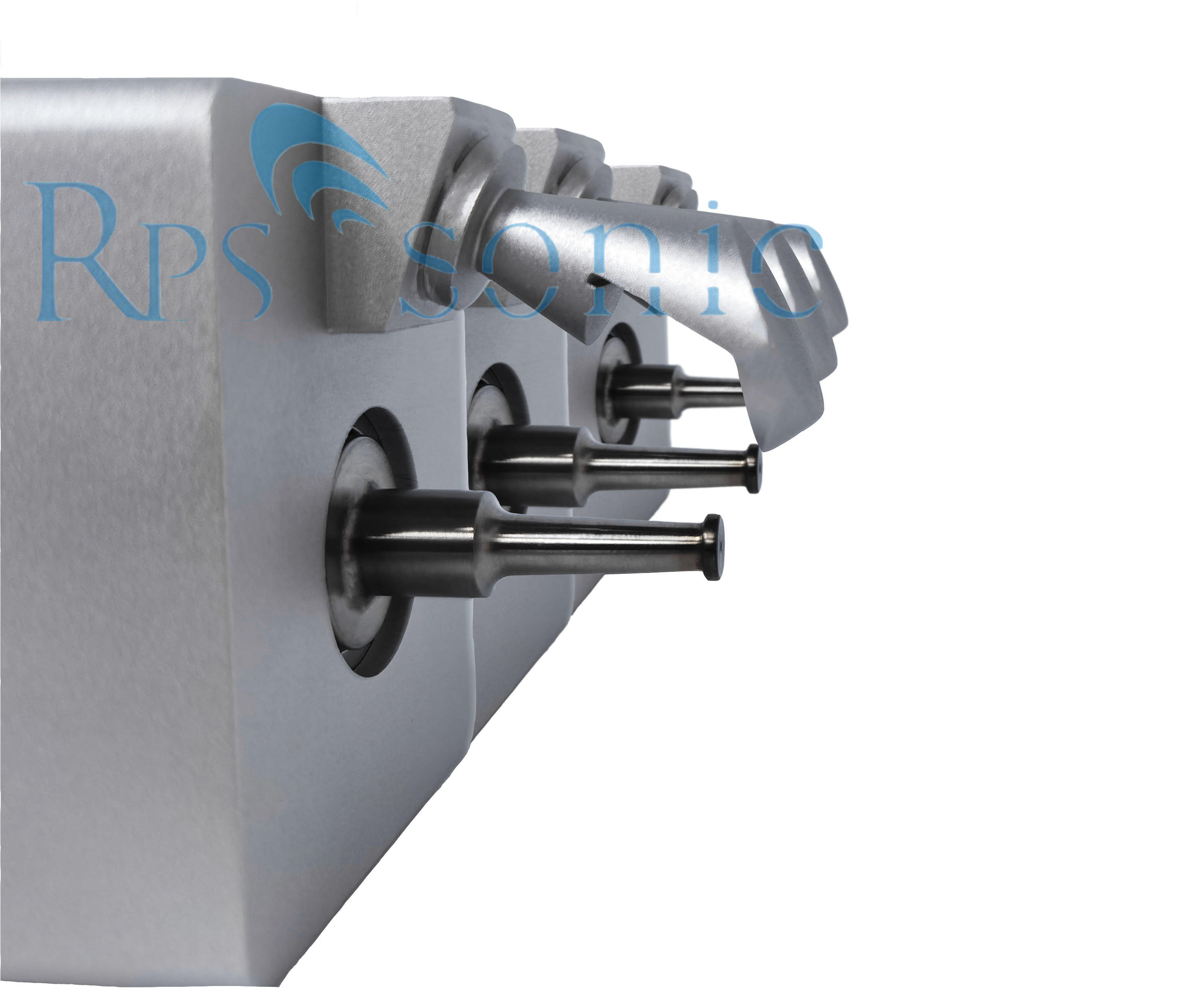

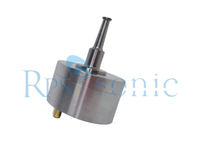

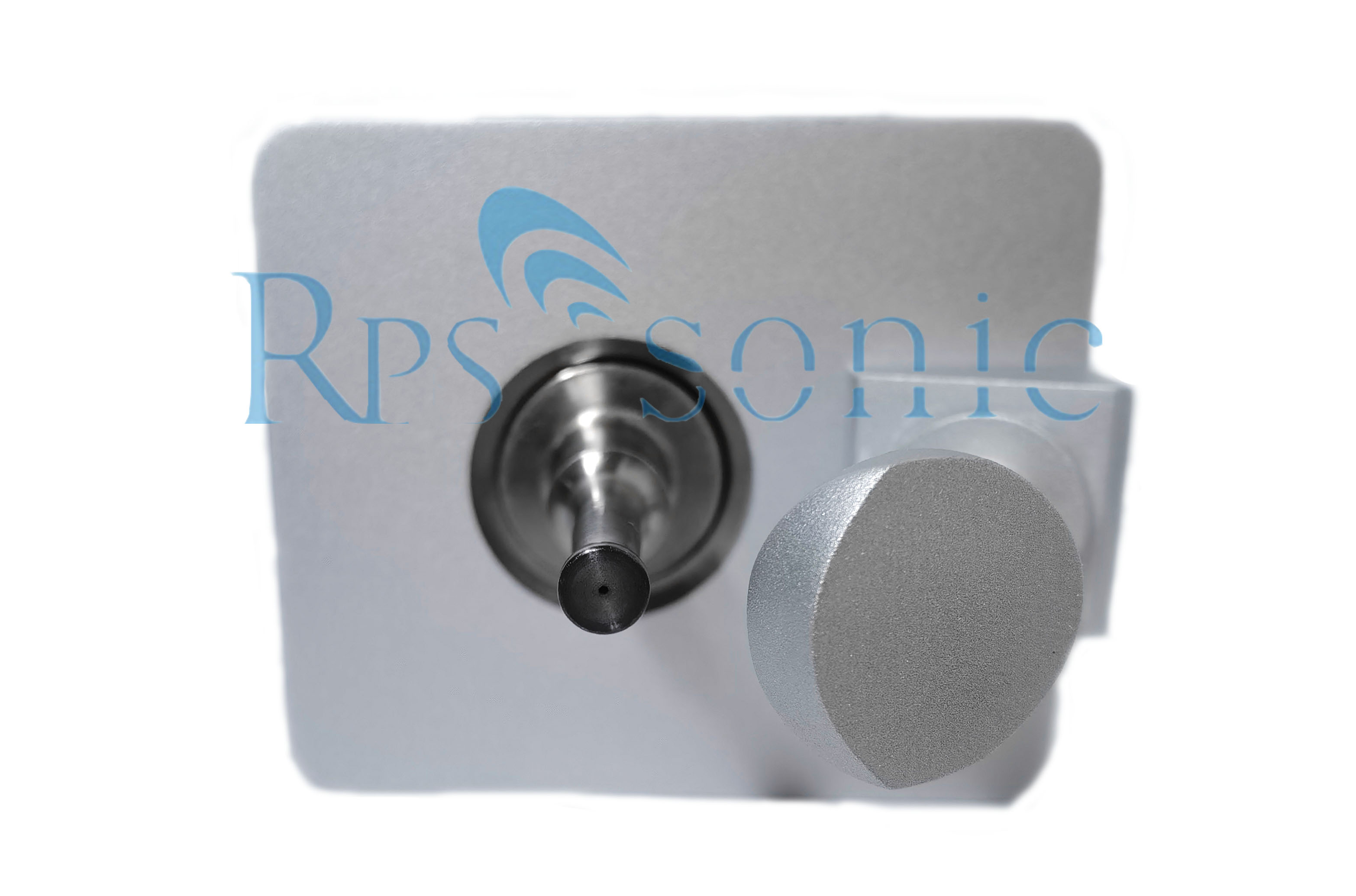

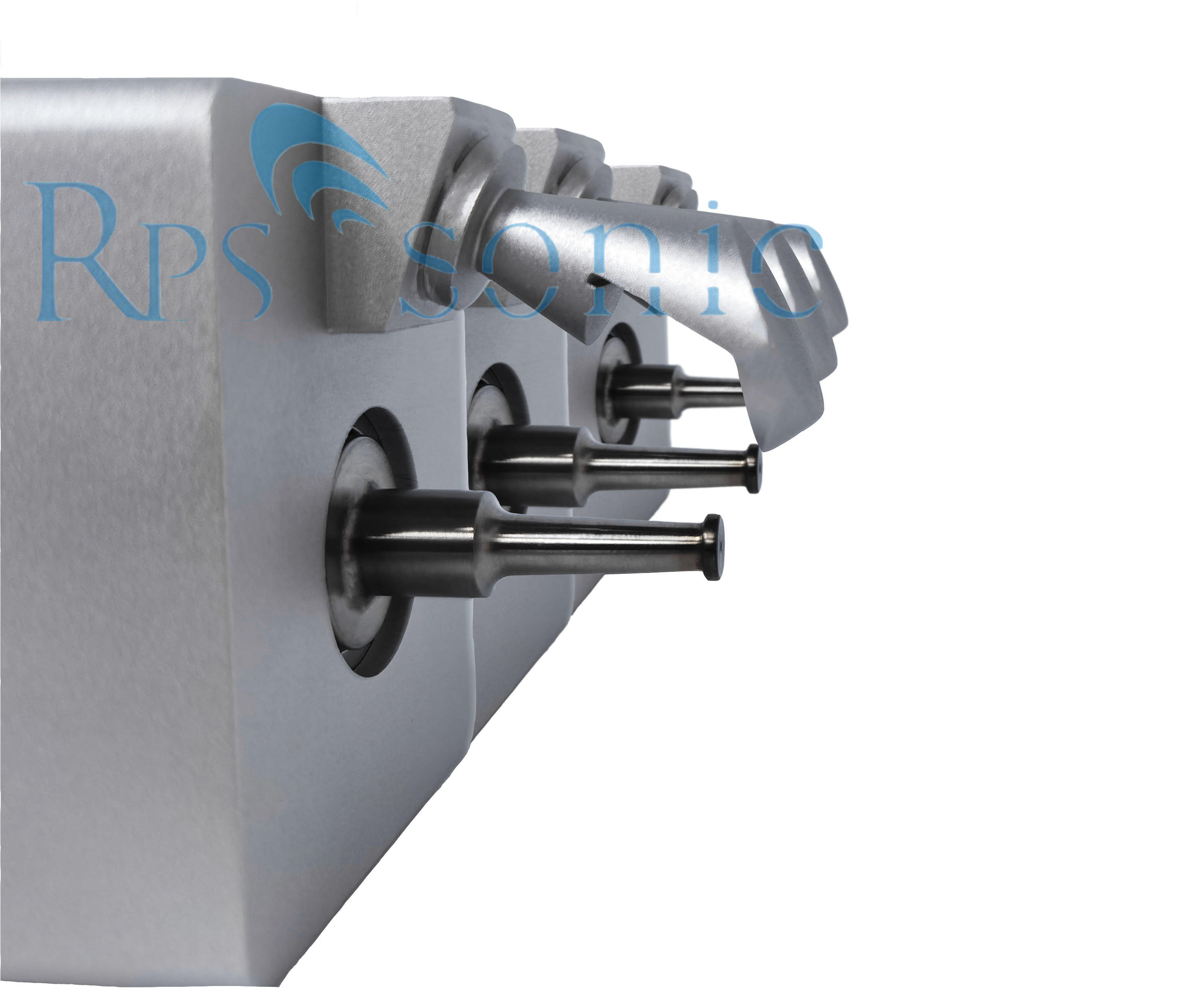

ultrasonic spraying nozzles are light weight flow through design for introducing liquids at the back of the nozzle. With nozzle materials made from titanium, stainless steel and fluoropolymer, many different solutions can be made into a mist. Sonaer ultrasonic atomizers are easy to clean, maintain, reliable and have no moving parts to wear out. Without the use of air pressure, varying viscosity liquids are pumped through the center of the nozzle, and is atomized.

How Ultrasonics Spray Nozzles Work

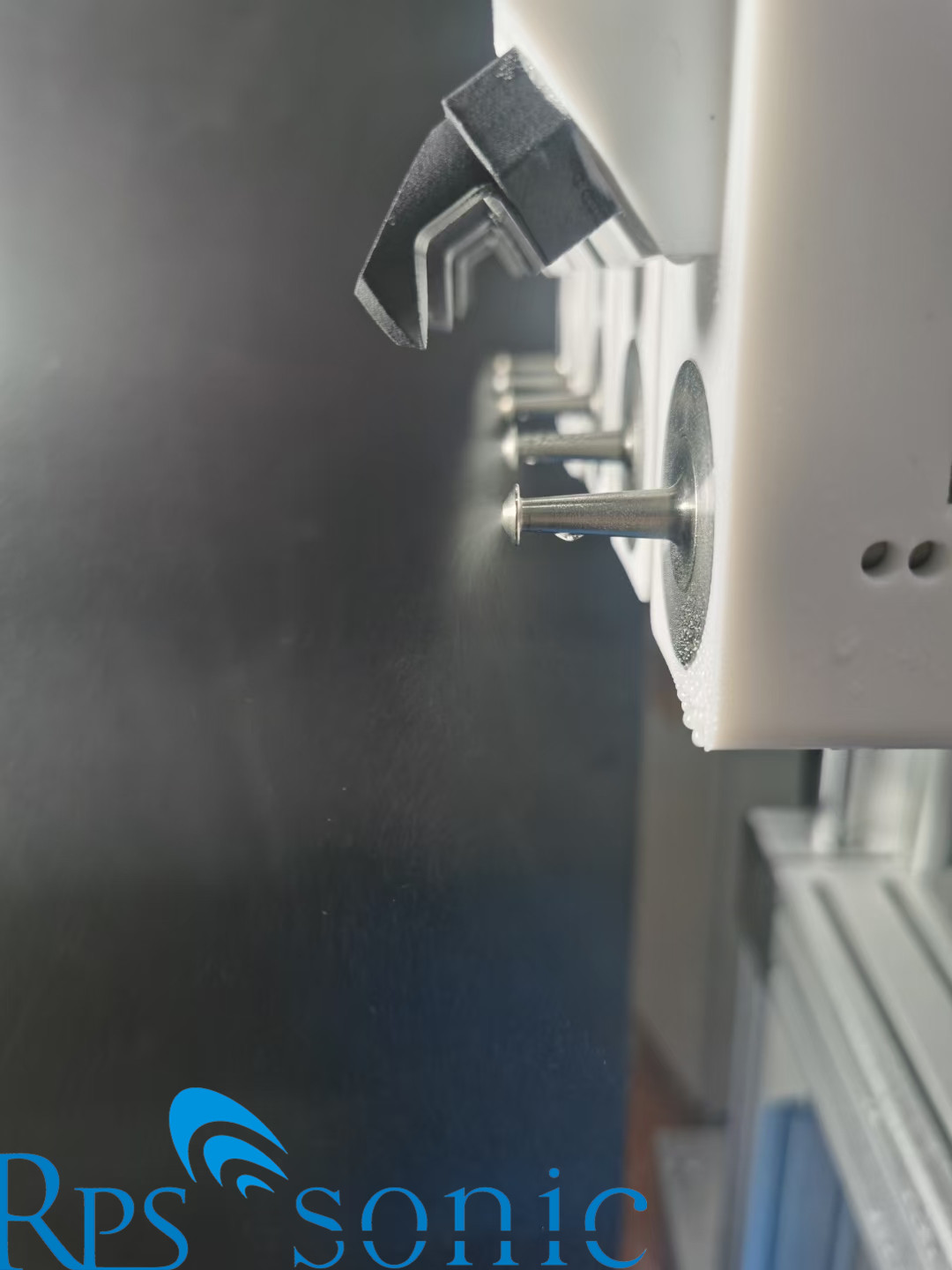

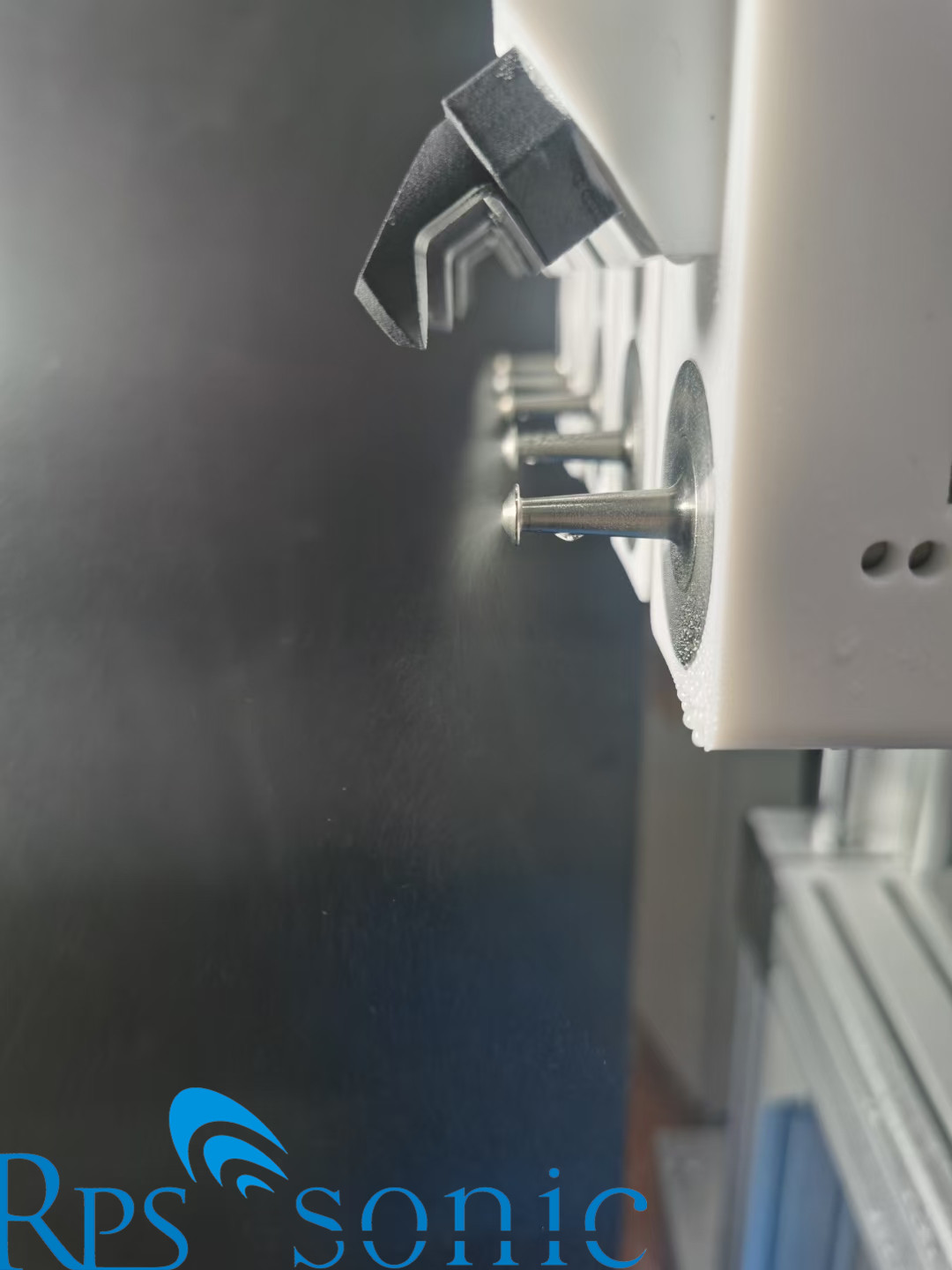

Ultrasonic spray nozzles are constructed to vibrate longitudinally at high frequency by means of piezoelectric transducers. This longitudinal up and down motion creates standing waves in a thin film of applied liquid on the ultrasonic nozzle tip, in which the amplitude of these waves can be controlled by the power generator. These standing liquid waves can be extended upwards off the ultrasonic nozzle tip to the point they separate into evenly sized droplets with little to no kinetic energy (see video). Secondary shaping gas or ambient air can be used to easily entrain droplets to the desired shape and velocity if needed. A variety of ultrasonic nozzles are offered that help determine droplet size, liquid flow rate and spray patterns.

Microspray works closely with Universities, R&D efforts and industry to provide solutions utilizing ultrasonic spray nozzles for a variety of cutting edge technologies as well as established industrial applications. Ultrasonics nozzles (also referred to as an ultrasonic nebulizer) have been a preferred choice over conventional air spray applicators, dip coating processes and other coating methodologies for many of the unique features ultrasonic spray coating nozzles provide. For example, an ultrasonic nozzle is an air-less systems, the ultrasonication of the spray nozzle makes it anti-clogging and the spray nozzle is constructed of highly durable materials such as titanium making it well suited for a variety of challenging environments and chemistries.

Parameter:

| Item | Parameter |

| Frequency | 50Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~20ml/min |

| Spray width | 2~200mm |

| Solution utilization | above 98% |

Advance:

High Transfer Efficiency – Reduces materials usage

Non clogging – Able to handle high-solid materials

Durability – Titanium construction is resistant to many solvents and abrasion.

Highly uniform distribution of droplet sizes – Reduces coating imperfections.

Airless spray – Can easily control process and also ideal for vacuum environments!