What's industrial Syringe Pumps?

Industrial syringe pumps are a specialized type of syringe pump designed for use in industrial and manufacturing settings, rather than just in medical or research applications.

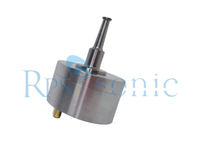

Ultrasonic atomization spraying is the use of piezoelectric effect to convert electrical energy into high-frequency mechanical energy, to break up the molecular bonds between liquid water molecules to produce a natural and elegant water mist, so as to atomize the liquid without heating or adding any chemical reagents. .

Ultrasonic high-frequency oscillation is used to atomize the liquid into uniform micron-sized particles. Compared with traditional pressure nozzles, ultrasonic spraying can obtain a more uniform, thinner and more controllable film coating, and it is not easy to block the nozzles. Because the ultrasonic nozzle only needs a tiny air volume of kilopascals, and there is almost no splash during the spraying process, the paint utilization rate is as high as 90%. In the ultrasonic spraying process, the droplet size and distribution can be precisely controlled, so that very small droplet particles can be quickly evaporated, thereby producing particles with a high specific surface area.

Basic Info.

Some key features and uses of syringe pumps include:

1.Precise fluid delivery: Syringe pumps can deliver fluids at very accurate and consistent flow rates, ranging from microliters to milliliters per hour. This makes them useful for administering medications, feeding solutions, and conducting research experiments that require precise fluid control.

2.Programmable operation: Most syringe pumps allow users to set the flow rate, volume to be delivered, and other parameters, enabling automated and reproducible fluid delivery. This helps ensure consistent treatment or experimental conditions

.

3.Versatility: Syringe pumps come in a variety of sizes and configurations to accommodate different syringe sizes and applications. They can be used with a wide range of fluids, from simple saline solutions to more complex drug formulations.

4.Continuous infusion: Syringe pumps can provide a steady, uninterrupted flow of fluids, which is important for maintaining consistent drug levels or sample delivery in various medical and research settings.

5.Safety features: Modern syringe pumps often include safety features such as occlusion detection, run-dry protection, and programmable alarms to help prevent accidents or issues during operation.

Intelligent interactive system

✓ Syringe parameter AI self recognition technology (compatible with 12 global brand specifications)

✓ Experimental parameter configuration storage (>50 sets of formula memory)

✓ Three anti touch panel (splash proof/anti misoperation/anti glare)

Five dimensional control mode

Injection/extraction/circulation infusion/gradient infusion/external trigger mode can be freely switched, with special configuration:

▶ Mass spectrometry dedicated pulse suppression mode

▶ Intelligent batch process sequence for microsphere preparation

▶ Safe suction protection mechanism for live experiments

Here are some key characteristics of industrial syringe pumps:

-

Robust construction: Industrial syringe pumps are built to withstand harsher environments, featuring durable materials and enclosures that can handle vibrations, dust, and other challenging conditions found in industrial facilities.

-

2.High-volume capacity: While medical syringe pumps typically accommodate smaller syringe sizes, industrial models can handle larger syringes and pump higher volumes of fluids, often up to hundreds of milliliters per minute.

-

3.Advanced controls: Industrial syringe pumps often have more sophisticated control systems, allowing for precise programming of flow rates, volumes, and other parameters. They may integrate with PLCs, SCADA systems, or other industrial automation equipment.

-

Specialized applications: Common uses of industrial syringe pumps include:Adhesive and sealant dispensing Potting and encapsulation of electronic components Precise metering of lubricants, greases, or other industrial fluids Automated filling and dosing of chemicals, paints, or coatings Controlled delivery of reagents or samples in industrial analytical instruments

5.Customization options: Industrial syringe pump manufacturers often offer a range of customization options to meet the specific needs of different applications, such as custom pump heads, tubing, and mounting configurations.

6.Regulatory compliance: Depending on the industry and application, industrial syringe pumps may need to meet certain regulatory standards, such as those related to food safety, pharmaceutical manufacturing, or hazardous material handling.