Description

Ultrasonic atomization spraying is the use of piezoelectric effect to convert electrical energy into high-frequency mechanical energy, to break up the molecular bonds between liquid water molecules to produce a natural and elegant water mist, so as to atomize the liquid without heating or adding any chemical reagents. .

Ultrasonic high-frequency oscillation is used to atomize the liquid into uniform micron-sized particles. Compared with traditional pressure nozzles, ultrasonic spraying can obtain a more uniform, thinner and more controllable film coating, and it is not easy to block the nozzles. Because the ultrasonic nozzle only needs a tiny air volume of kilopascals, and there is almost no splash during the spraying process, the paint utilization rate is as high as 90%. In the ultrasonic spraying process, the droplet size and distribution can be precisely controlled, so that very small droplet particles can be quickly evaporated, thereby producing particles with a high specific surface area.

Ultrasonic vibrations can create very thin droplets. During ultrasonic spraying, the droplet size and distribution can be precisely controlled so that very small droplets and particles can be vaporized.

Thereby, particles with high surface area are produced. The ultrasonic spay and atomization is a successful technology e.g. to apply thin coatings of high performance and quality to a substrate. Due to the acurate control over all process parameters of the ultrasonic atomization, overspraying can be avoided and a precise droplet distribution is achieved. Another very potential application is the ultrasonic spray drying or freezing.

Ultrasonic Spraying of Ultra-Fine Droplets The ultrasonic spraying technique is implemented in various industrial branches for manifold applications. Most common fields of ultrasonic nebulizing and atomization are the thin-film coating and the spray drying or spray freezing of particles. As an industrially proven technique, ultrasonic spraying is successfully implemented in production lines of high performance thin film coating during the manufacturing process of precision electronics such as semiconductors, precision devices, nanotechnology applications, fuel cells, and solar cells. In the food industry, ultrasonic spraying is used to promote the spray freezing of powders, e.g. coffee, milk, whey and other powders.

Basic Info.

| Model NO. | RPS-S100 |

| | 0.5-20ml/Min |

| | 2-20mm |

| | 30-80mm |

Suitable for Liquid Viscosity | <30cps |

| | <10um |

| | <0.05MPa |

| | Carton |

| | 100Khz |

| | RPS-SONIC |

| | China |

| | 8515900090 |

| | 200/Month |

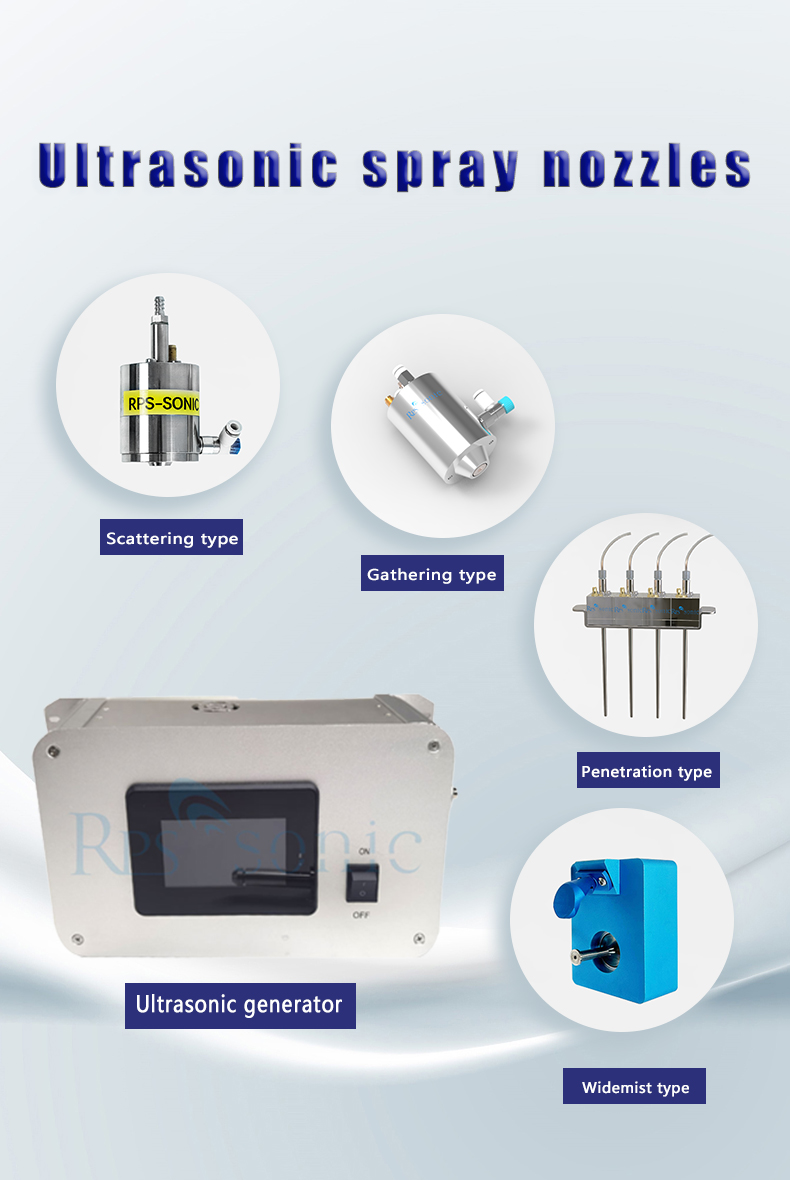

Focus mist ultrasonic spray nozzle is an ultrasonic atomizing nozzle with a small spraying width. The ultrasonic nozzle adopted the principle of ultrasonic atomizing technology. It has a special channel design of contracted flow to uniformly distributes the carrier gas, so that the liquid mist after ultrasonic atomization is sprayed in a focused manner, thereby reducing the spraying area of the ultrasonic spray nozzle. Due to the small width of the focus mist ultrasonic spray nozzle, it is mainly suitable for various small and medium-area spray coating applications. The focus mist ultrasonic nozzle is complementary to the wide mist ultrasonic nozzle and can be applied to almost all different plane spray coatings.

Features

Uniform coating: uniformity >95%

Saving raw materials: raw material utilization rate is over 85%, 4 times that of traditional air spray nozzle

High control accuracy of coating thickness : 20 nm to tens of micron coatings can be precisely sprayed.

Non clogging

Anti-corrosion nozzle

High precision, high controllable spray.

Industries and applications:

disintegration of liquids

thin-film coating for electronics

high performance coatings (e.g. containing functionalized nano particles)

anti-fog coating

adding moisture to a gas stream

encapsulation of active agents in pharmaceuticals

spray drying of powders and granules, e.g. nano-particles

food industry: milk & whey powder, instant coffee

particle engineering

spray drying of food powders, e.g. heat-sensitive products

in the production of semiconductors, fuel cells, medical equipment

chemistry: e.g. gas-liquid reaction, bondings