Description

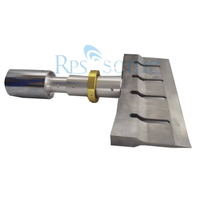

Ultrasonic welding uses an ultrasonic generator to convert 50/60 Hz current into 15, 20, 30 or 40 KHz electrical energy. The converted high-frequency electrical energy is converted again into mechanical motion of the same frequency through the transducer, and then the mechanical motion is transmitted to the welding head through a set of horn devices that can change the amplitude. The welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, the vibration energy is converted into heat energy through friction, melting the plastic.

Principle of ultrasonic cutting: The grinding wheel blade generates instantaneous telescopic vibration in the radial direction through the action of ultrasonic waves, which can cause repeated collisions between the abrasive grains and the workpiece under high acceleration in a very short period of time. As a result, the workpiece is processed while generating a fine fracture layer on its surface, so the processing load on the grinding wheel blade can be significantly reduced.

Ultrasonic Slitting machine combine the function of welding and cutting, is a kind of mechanical equipment that cuts wide paper or film into multiple narrow materials, and is often used in papermaking machinery and printing and packaging machinery.

Features

Efficient----The fastest cutting can reach 10 meters per minute.

Intuitive----The adjustment operation is convenient and intuitive.

Quality----Automatic edge sealing, no burning, no blackening, no burrs.

Economical----automatic work, saving labor, one person can operate multiple machines.

Application

Velcro ultrasonic slitting machine is widely used in clothing industry, shoe and hat industry, luggage manufacturing industry, craft decoration industry, packaging industry and so on. Applicable to: Ribbon, cloth tape, Velcro, ribbon, satin ribbon, ribbon, etc.