20khz Ultrasonic Welding System for Surgical Mask N95 Ear Loop Welding

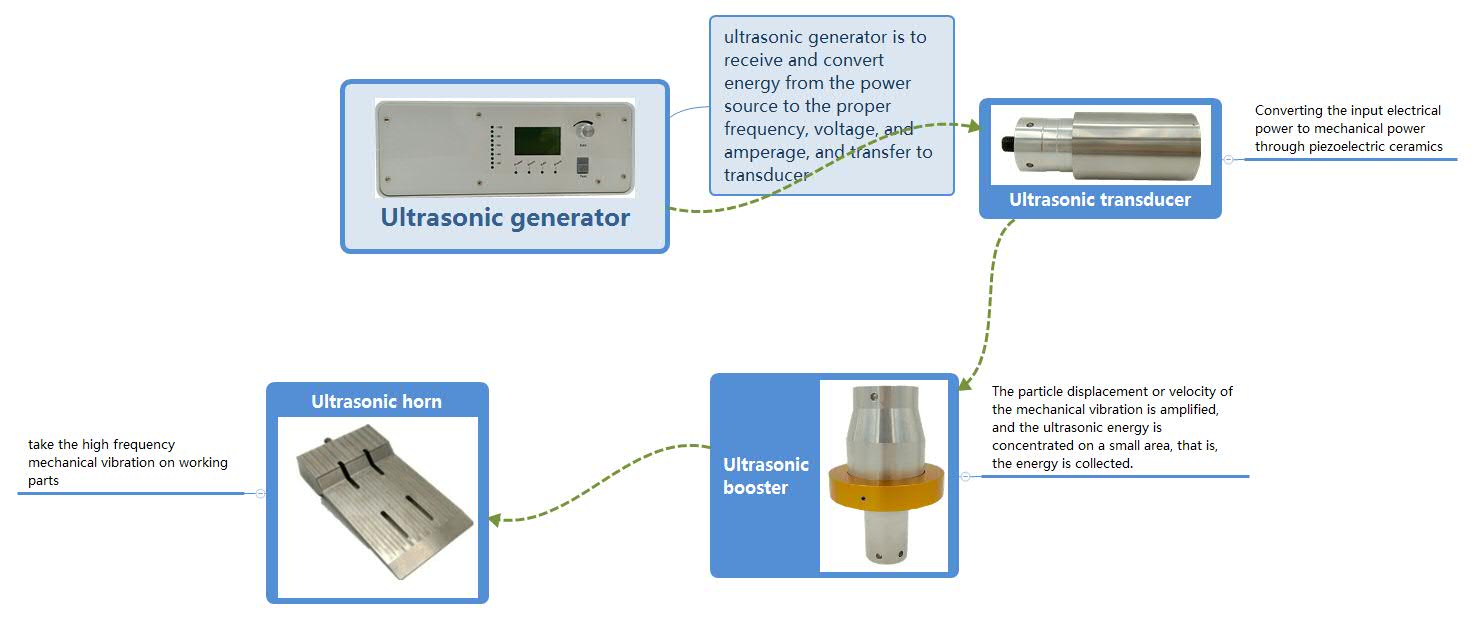

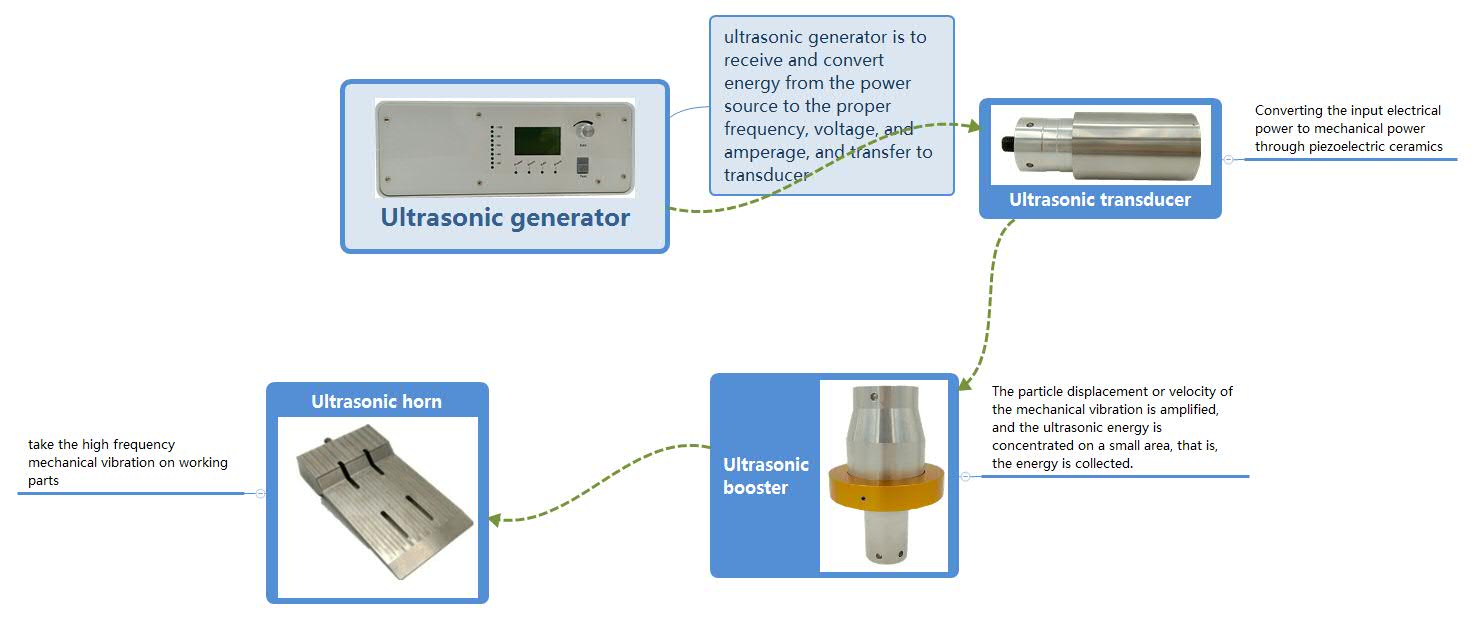

What’s ultrasonic generator?

Ultrasonic generator, usually called ultrasonic power supply. Its function is to convert our mains (220V 110V or 380V, 50 or 60Hz) into a high frequency AC signal that matches the ultrasonic transducer. From the form of the amplifying circuit, a linear amplifying circuit and a switching power supply circuit can be used, and the high-power ultrasonic power source generally adopts a circuit form of a switching power supply in terms of conversion efficiency. Linear power supplies also have their own application range, which has the advantage that the circuit can be not strictly required.

Matching allows the operating frequency to change continuously and continuously. From the current situation in the ultrasound industry, ultrasonic generators are mainly divided into self-excited and separate excited power supply.

The principle of the ultrasonic generator is to first generate a signal of a specific frequency by a signal generator, which may be a sinusoidal signal or a pulse signal. This specific frequency is the frequency of the transducer, and is generally applied to ultrasonic in an ultrasonic device. The frequency is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz,70khz, 100KHz.

The transducer part :

l With best PZT8 in China

l The impedance of the transducer is less than 8 and the impedance of the transducer and welding horn is less than 40.

l 5times test for ultrasonic check

l 3hours Temperature rise detection

l To confirm all your transducer with horn no matching problem.

Item | Parameter |

Frequency | 20KHZ |

Power | 2000W |

Horn size | 110*20 |

Horn material | Steel or Titanium alloy |

weight | 14.5kg |

Generator part

Transducer material and ultrasonic welding horn material are both critical.

There are two key materials in the transducer, piezoelectric ceramic sheet & aluminum. The piezoelectric ceramic sheet mainly affects the temperature rise of the ceramic sheet. Good ceramic chips, such as: China Risheng, Germany Serang, the basic temperature rises to about 50 stable. The maximum temperature that the ceramic chip can withstand is 70 degrees, so good temperature rise control is the first key to service life. RPS-SONIC chooses Risheng ceramic chips, and never uses ceramic chips from other small brands.

The aluminum material of the transducer mainly bears the pressure of the transducer. Therefore, high-quality aluminum must be used. If the aluminum material is not good, the aluminum crack of the transducer may occur. RPS-SONIC's aluminum transducers are all imported from Japan.

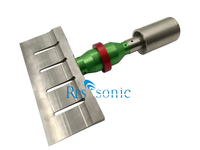

ultrasonic welding horn materials mainly involve heat dissipation and service life issues. Generally, steel molds are used in mask machines, but in fact, considering the service life issue, titanium alloy abrasive tools are the best choice. In the heyday of the mask machine, the time to change an abrasive tool may affect your income of tens of thousands, so under conditions, it is better to choose titanium alloy materials. Even the steel membrane involves many material issues, such as skd11, DC53, D2, etc., so good abrasive tools cannot be separated from good materials. Of course, price is also a very important factor. RPS-SONIC provides molds of various models and materials, you can choose according to your own usage. There is no problem with custom abrasives.

Features:

Automatic frequency tracking: The system automatically tracks the resonance frequency of the welding horn. Compensate for detuning caused by heat and other reasons.

Digital frequency control: The operating frequency is digitally controlled by the microcontroller.

Digital amplitude setting: This feature allows users to set precise amplitudes according to application requirements, which provides a larger range and repeatability of settings than analog systems.

The amplitude can be adjusted in a large range: 1% ~ 100% continuously adjustable, which is different from the shortcomings of traditional generators that are difficult to work with low amplitude.

High-speed micro-controller: The internal micro-controller operates at a frequency of up to 168MHz, which can accurately and timely control the working conditions.

Control and sampling interval of 0.5 milliseconds: 2000 times of sampling and control for welding process per second.

Color touch screen display: Through the color screen and touch, friendly and easy-to-use human-computer interaction is realized, and the experience is better.

Coexistence of buttons and touch: common functions can provide better interaction through buttons. Among them, the buttons use silicone keys, which have a better feel.

Operating language: The user can select the applicable language in the start screen: currently only supports English and Chinese.

Slant start: Ultrasonic energy supply and welding horn start at the most suitable ascent speed to reduce the electromechanical pressure of the system.

Vibration after welding: The user can start the ultrasonic after the welding and pressure holding process is finished, and the workpiece sticking to the welding horn will be shaken off.

Welding quality monitoring: user-definable process alarm. When it is outside the range of user-defined defective products, the system will generate an alarm to remind