Description

Spray gun cups are containers that hold paint for specific spray gun systems, including siphon, HVLP, conventional, pressure, and handheld sprayers, offering instant access to a stored supply of paint.

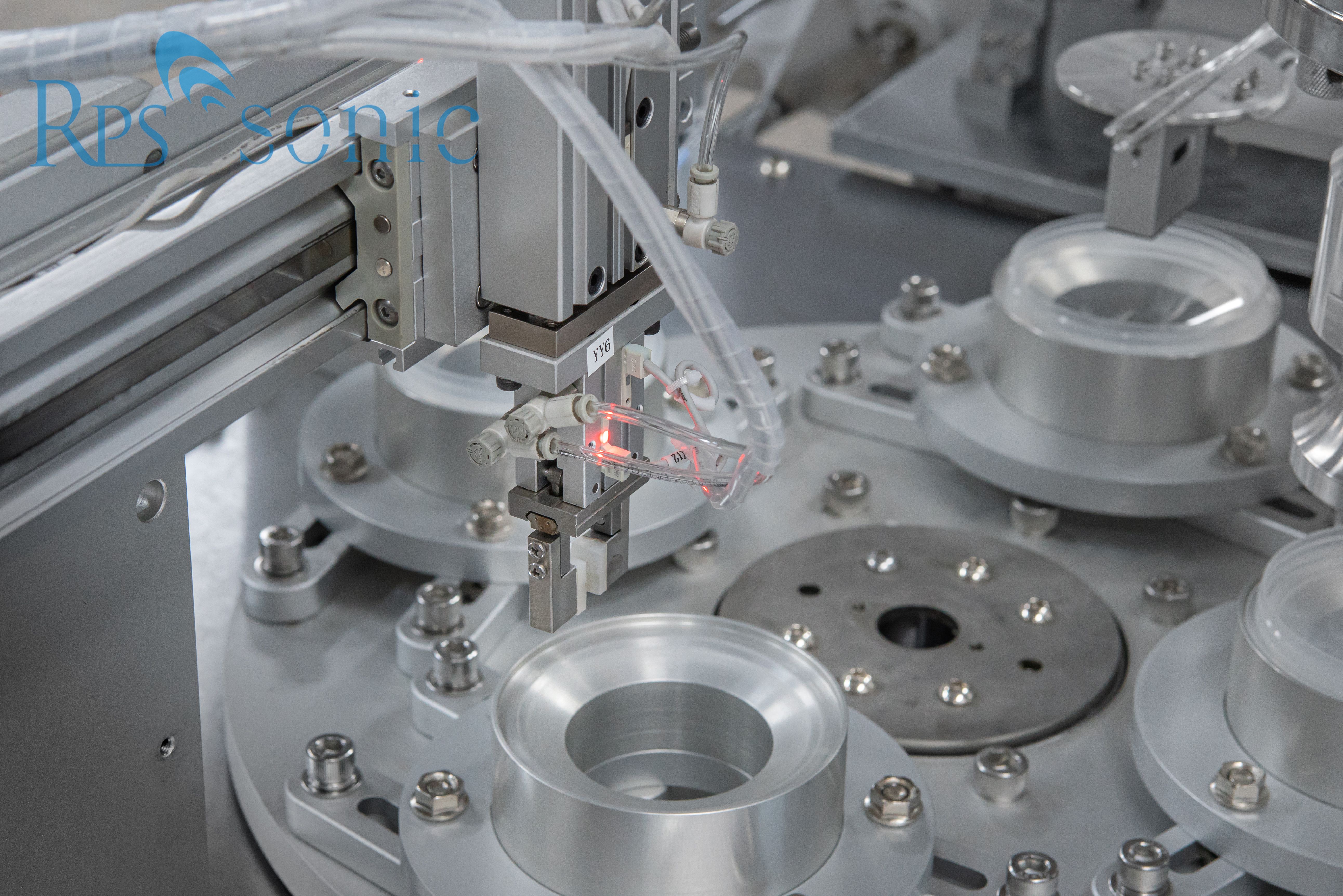

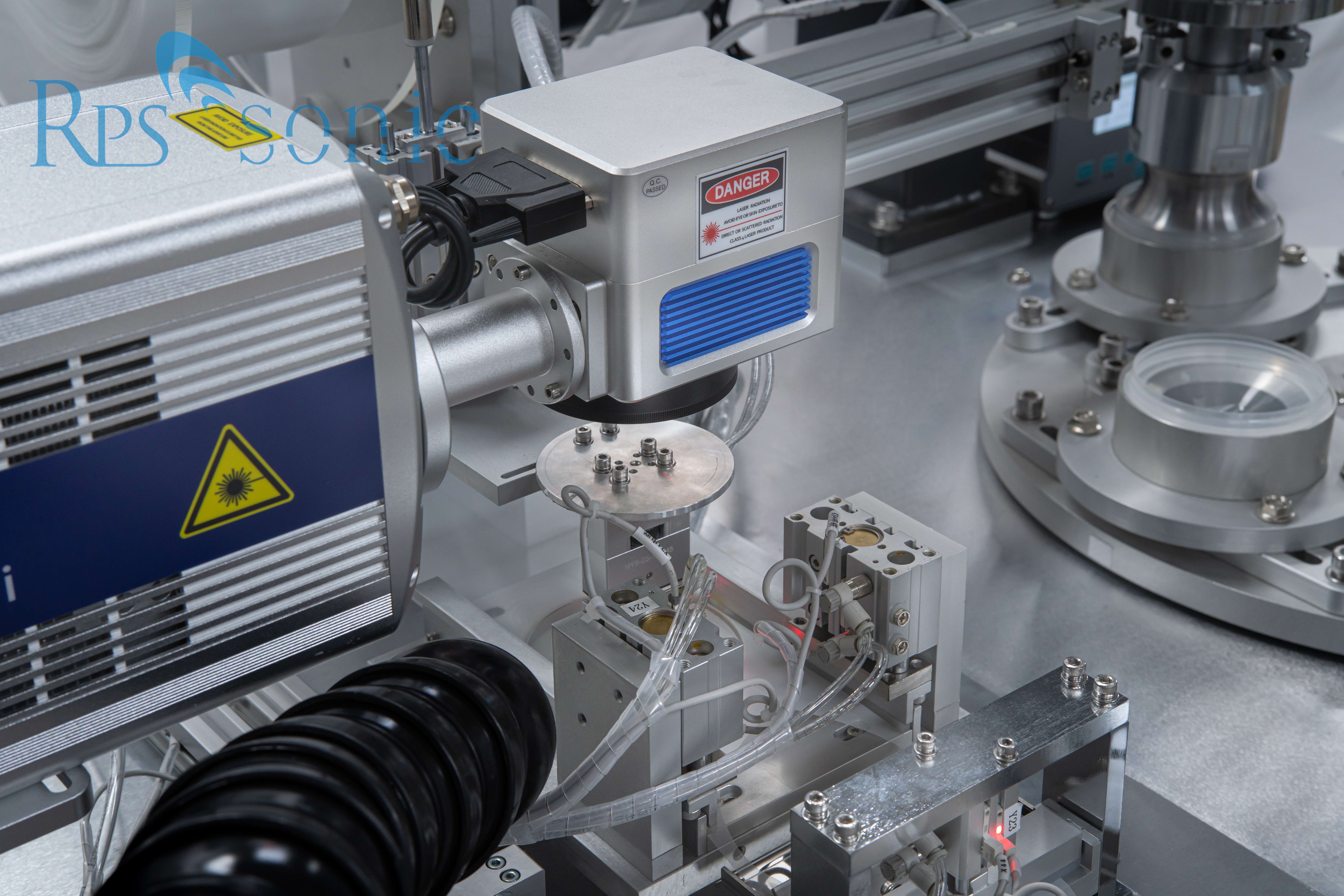

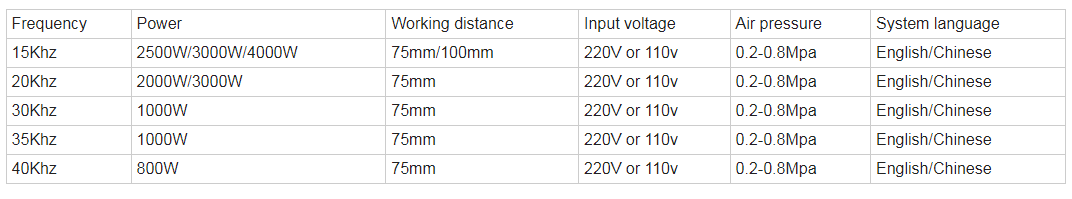

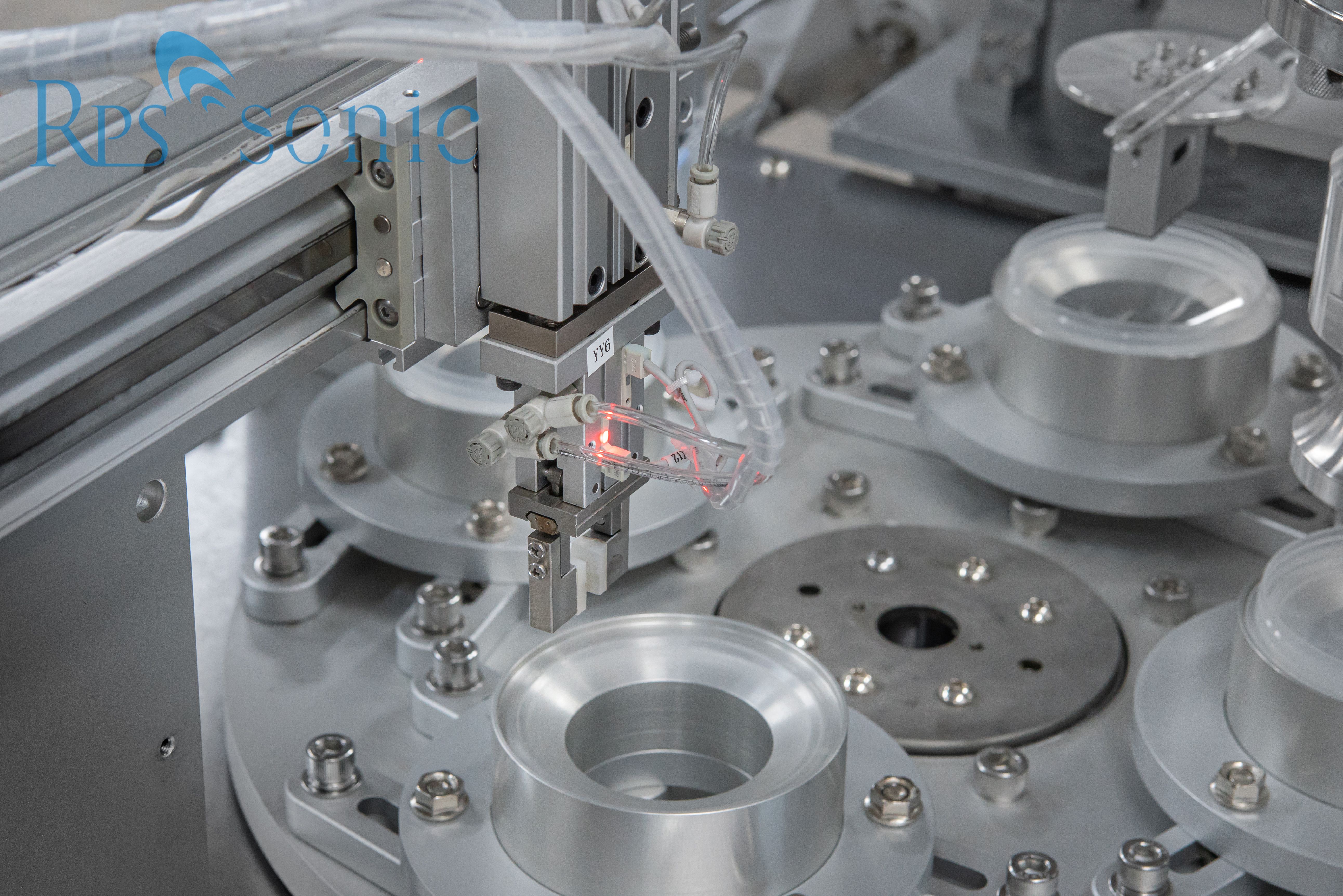

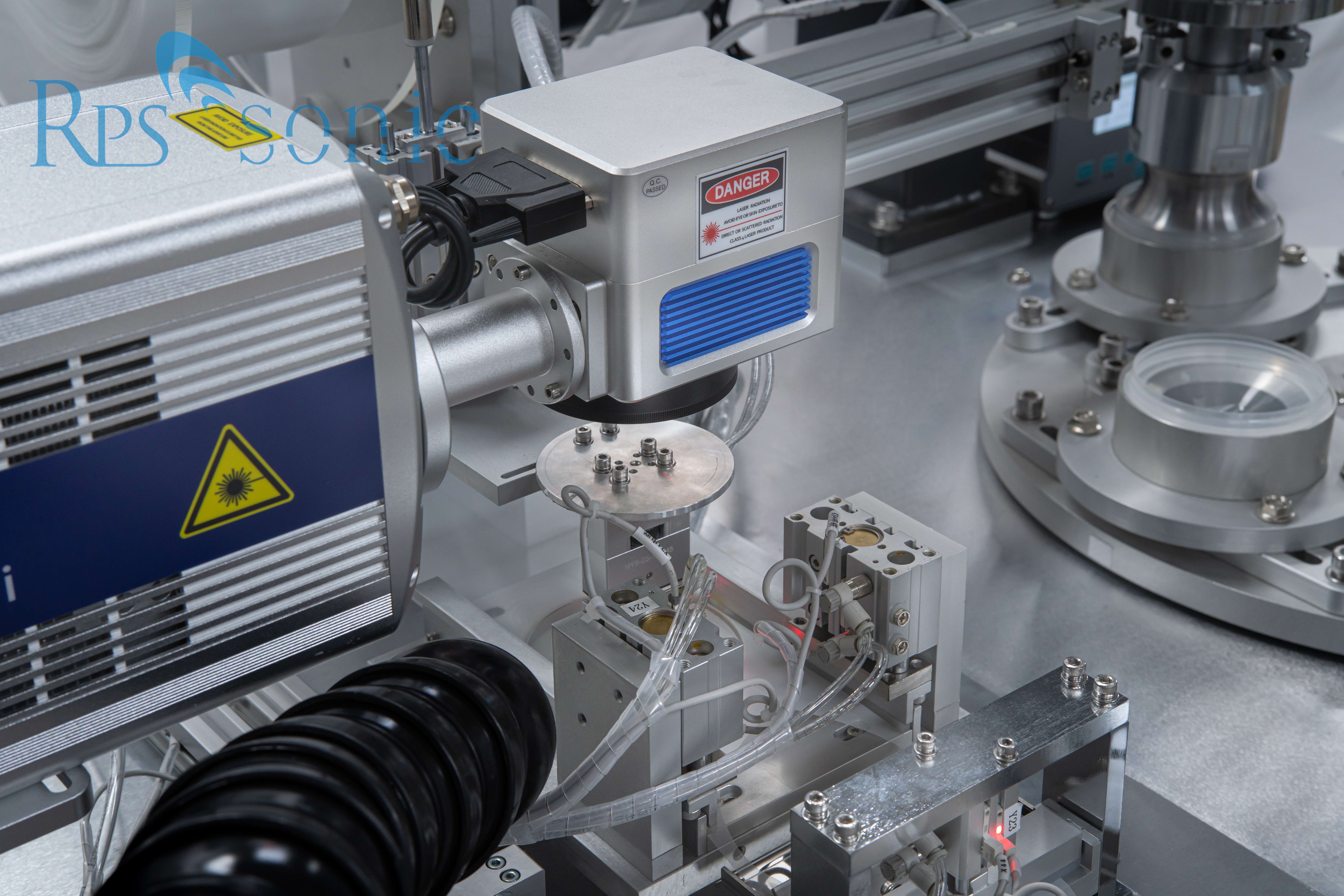

Our company provide the solution to weld the cup of Paint Spray Gun.

Automatic ultrasonic welder can replace 3 or 4 labors, save a lot of cost of labor and time.

What's the ultrasonic welding machine?

The process of ultrasonic welding eliminates the use of glue and allows the thermoplastic parts to bond to itself. Ultrasonic welding with the proper time setting and pressure is the fastest most reliable method for thermoplastic parts welding.

* Eliminate use of consumable material

* Produce airtight and watertight seams

* Increase production time

Main Features

1. High Speed: Automatic Indexing Rotary Table with 6/8/10/12 stations for continuously manufacturing.

2. Equipped with a robot arm to unload welded work piece automatically.

3. Optional Automatic Film Feeder to protect the work piece surface being damaged by the ultrasonic vibration.

4. PLC/ IO easy operation touch screen , English Interface.

5. Analog Ultrasonic Welding Machine, manually tuning.

6. Welding by time, Delay time, Weld Time and Hold Time.

7. Separate generator design, more convenient.

8. Precise imported pneumatic parts

9. High quality transducer and booster

10. Self-protection: Over-Current, Frequency Deviation, Over-Temperature

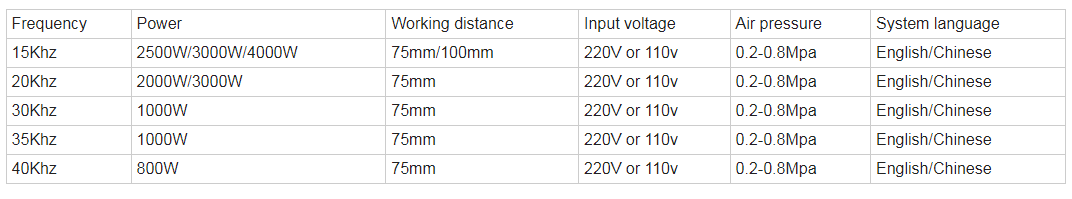

Parameter

Ultrasonic welding machines are widely used in automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry, and so on.

Automotive industry: plastic body parts, car doors, automotive dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, plastic filter for motorcycle , Radiator, brake fluid tank, oil cups, water tanks, fuel tank, air hose, exhaust purifiers, the tray plate, and so on.

Plastic Electronics: prepaid water meters, communications equipment, cordless phones, mobile phone accessories, cell phone case,battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connection, and so on.

Stationery: folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges, and so on.

Medical and Daily products: watches, kitchen utensils, oral liquid bottle caps, drip caps, mobile phone accessories, golden soft brush, and daily necessities, handle, security caps, cosmetics bottle, coffee pot, washing machines, air dehumidifiers, Electricirons, electric kettles, vacuum cleaners, speakers, cover and metal face grille and other civil engineering and so on.

Health products: children's products, air mattresses, clothes hangers, gardening supplies, kitchenware sanitary ware, shower, shower head, and so on.

Application

PET packaging

In PET applications, ultrasound can quickly reach high melting points and increase yield. Sealing and separation of blister can be realized, Kaifeng and genuine anti-counterfeiting functions can also be easily implemented.

Soft drink packaging

Ultrasonic welding is particularly suitable for coated cardboard packaging materials. Although the product is wet, it can still ensure the tightness of the weld seam, and it does not matter whether it has an aluminum film. The nozzle can be integrated normally. Short sealing time and high yield. Repeatable welding parameters ensure consistent seal quality.

Film packaging

Ultrasonic energy safely separates residual product in the weld zone to ensure absolute sealing. So that it can be significant. Reduce the number of packaging leaks and increase product durability. Lingke Ultrasound in stand-up bag, zipper bag and hose bag.This advantage is fully demonstrated in longitudinal continuous welding and horizontal intermittent welding.

Shell & top cover

The sealing of the top cover film, the welding of the sealing ring and the sealing of the filter packaging are the most important kinds of solutions using ultrasound

To the application. The welding mold positions the film by vacuum. Heating-free molds ensure durability and protect the product.