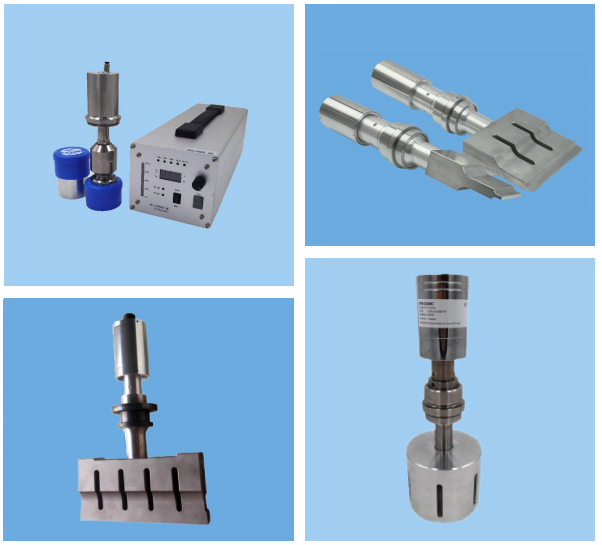

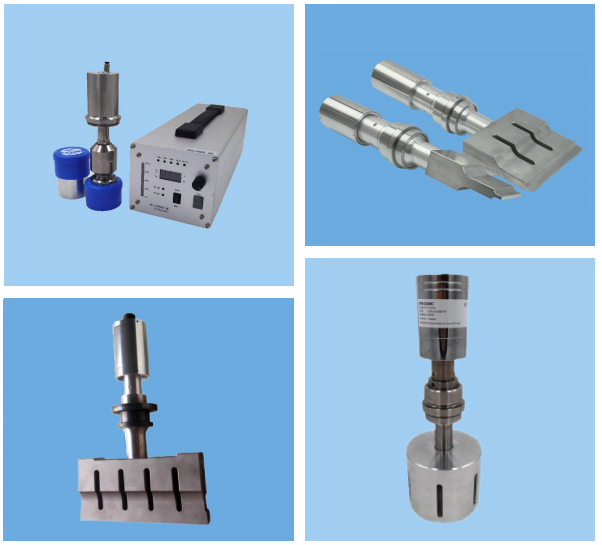

Ultraosnic Welding System Welding Transducer for Welding And Sealing

Ultrasonic Welding Vibrator usually refers to the ultrasonic transducer + ultrasonic booster + ultrasonic horn. The principle of ultrasonic welding is to use high-frequency vibration to melt the part of the contact material and achieve welding effect after cooling. So all thermoplastic materials can be ultrasonically welded. It is typically the most important and diversified component in ultrasonic welding system. It usually needs to be customized according to the shape of different ultrasoni c welding parts. By matching the bottom mold, it achieves different shapes, patterns, and welding effects with different areas.

Advantage of Ultrasonic welding system:

1. Avoid the harmful substances of glue contaminating the beverage.

2. Good tightness, not easy to leak.

3.Ultrasonic welding is not affected by time, it is permanent and firm, and the glue will usually crack after standing for a long time.

4. Save labor cost, adopt ultrasonic welding, the whole welding process is about 2 seconds, fast and convenient.

Material excellent: High-quality steel or titanium and aluminum are used as the raw materials for the horn, to ensure the service life of the welding horn. Different materials for different applications, we will suggest optimal results.

Strong output: Through the professional software analysis, the resonant frequency of the oscillator in consistent to achieve maximum amplitude. Therefore, the output power is stronger, and the service life is longer.

Well stability: Professional design & analysis, strict frequency testing and aging testing to ensure that the ultrasonic oscillators received by customers are stable in output.

![_(8MGXN{`E4O]7}R[QRKE)D](//iirorwxhjionlo5p.ldycdn.com/cloud/nnBpqKrrRlkSpiqkiljki/_-8MGXN-E4O-7-R-QRKE-D.png)

Why RPS-SONIC Transducer:

Piezoelectric transducer is the electric charge that accumulates in certain solid materials in response to applied mechanical stress.It is key point of the ultrasonic welding/cutting/sealing/jionting/bonding equipment.

The transducer decide the property of the machine.We can supply transducer,also transducer with house and booster.

We can supply Ultrasonic welding transducer/converter to replace some famous brand,such as Branson/Telsonic/Rinco/Dukane and obtained well reputation. Now we are developing customize transducer for whole machine company,welcome to inquire OEM transducers

Frequency: 15K-70Khz Available

Power: 100W- 5000W Available

Amplitude: 2μm - 20μm Available

Can customize depending on dimensions, frequencies, capacitance and other requirements, OEM services

Contact us for catalogue of the transducers. We have hundred types of ultrasonic transducers

Application

Ultrasonic welding machines are versatile and can be used for joining a wide range of materials, including plastics, metals, textiles, and films. They offer several advantages such as fast cycle times, precise control, and the ability to create strong, hermetic, and aesthetically pleasing welds. The specific configuration and features of an ultrasonic welding machine may vary depending on the application and the materials being welded.

Ultrasonic RPS Transducer

Ultrasonic Tube Sealing System

Ultrasonic Ribbon Puching System

Service and shipment

Warranty one year for transducer.

You can contact us for technical inquiry any time.

We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

We supply customized products service for small quantity also.

Shipment by FED-EX /DHL/UPS/TNT

Famous customer

![_(8MGXN{`E4O]7}R[QRKE)D](http://iirorwxhjionlo5p.ldycdn.com/cloud/nnBpqKrrRlkSpiqkiljki/_-8MGXN-E4O-7-R-QRKE-D.png)