Description

Welding principle

The electronic energy is converted into mechanical energy by ultrasonic vibration, and then the energy is transmitted to the contact surface of the plastic bow and arrow by the welding head (HORN), so that the principle of intense friction and heat generation occurs between the molecules, and the product is instantly melted and combined into one. Processing is fast, clean, beautiful and economical.

Welding range: toy industry, stationery industry, home appliance industry, electronics industry, food industry, communication industry, transportation industry, aerospace and so on.

Ultrasonic welding example

Daily necessities industry: powder box, cosmetic mirror, hair comb, lock ring, thermos cup, sealed container, seasoning bottle, water pipe joint, handle,bottle caps, food containers, car lamp shades, car water tanks...etc.

Toy industry: all kinds of ball toys, stationery, water guns, plastic gifts, music toys, and all kinds of plastic toys...etc.

Electrical appliance industry: electronic clocks, steam irons, vacuum cleaners, telephones, computer keyboards, electric fans, batteries, etc.

Automobile manufacturing: headlights, rear mirrors, interiors, bumpers, various plastic products...etc.

The principle of rotary welding is designed for plastic round thermoplastic products. The heat generated by the mutual friction of the plastic workpieces melts the contact surface of the plastic workpieces, and then relies on external pressure to drive the upper and lower workpieces to solidify into one, becoming permanent. sexual union.

Examples of rotary melting: RO filter, freezer cup, thermos cup, vase, carburetor, shower head, thermos air bladder, etc.

The hot plate welding principle uses the template to heat it to the required temperature, and then place it in the middle of the joint surface between the plastic workpiece and the workpiece, so that the heat is concentrated on the two joint surfaces. External pressure causes the workpieces to become one and become a function of solid durability. It can handle welded objects, and the products with high hardness, complex shape and huge volume can be solved.

Examples of hot melt: car lights, outdoor refrigerators, door panels, air pumps, water storage tanks, vacuum cleaners, hole balls, CD boxes, washing machine gimbal, rhythmic dance pedals, etc.

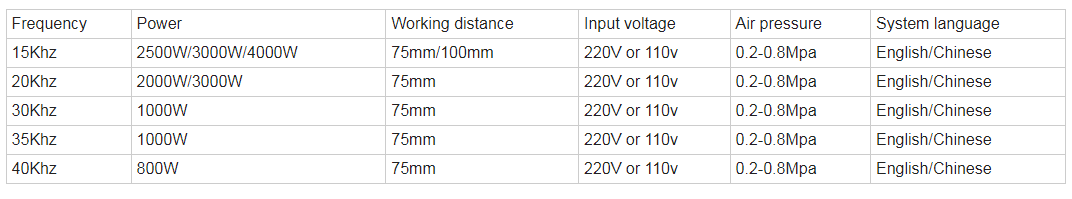

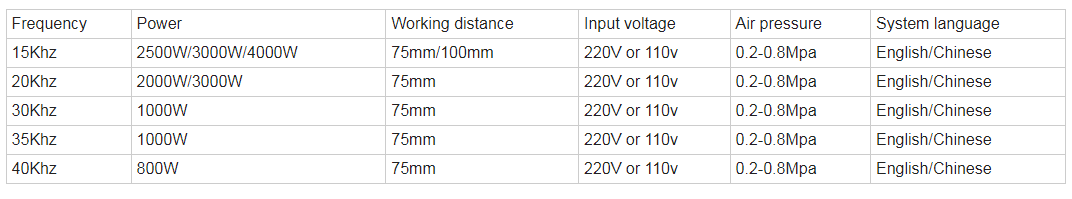

Parameter

Application

PET packaging

In PET applications, ultrasound can quickly reach high melting points and increase yield. Sealing and separation of blister can be realized, Kaifeng and genuine anti-counterfeiting functions can also be easily implemented.

Soft drink packaging

Ultrasonic welding is particularly suitable for coated cardboard packaging materials. Although the product is wet, it can still ensure the tightness of the weld seam, and it does not matter whether it has an aluminum film. The nozzle can be integrated normally. Short sealing time and high yield. Repeatable welding parameters ensure consistent seal quality.

Film packaging

Ultrasonic energy safely separates residual product in the weld zone to ensure absolute sealing. So that it can be significant. Reduce the number of packaging leaks and increase product durability. Lingke Ultrasound in stand-up bag, zipper bag and hose bag.This advantage is fully demonstrated in longitudinal continuous welding and horizontal intermittent welding.

Shell & top cover

The sealing of the top cover film, the welding of the sealing ring and the sealing of the filter packaging are the most important kinds of solutions using ultrasound

To the application. The welding mold positions the film by vacuum. Heating-free molds ensure durability and protect the product.

English

English