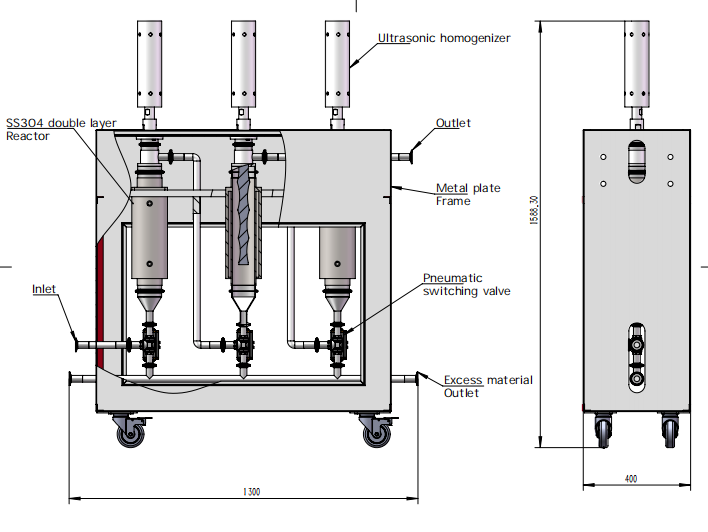

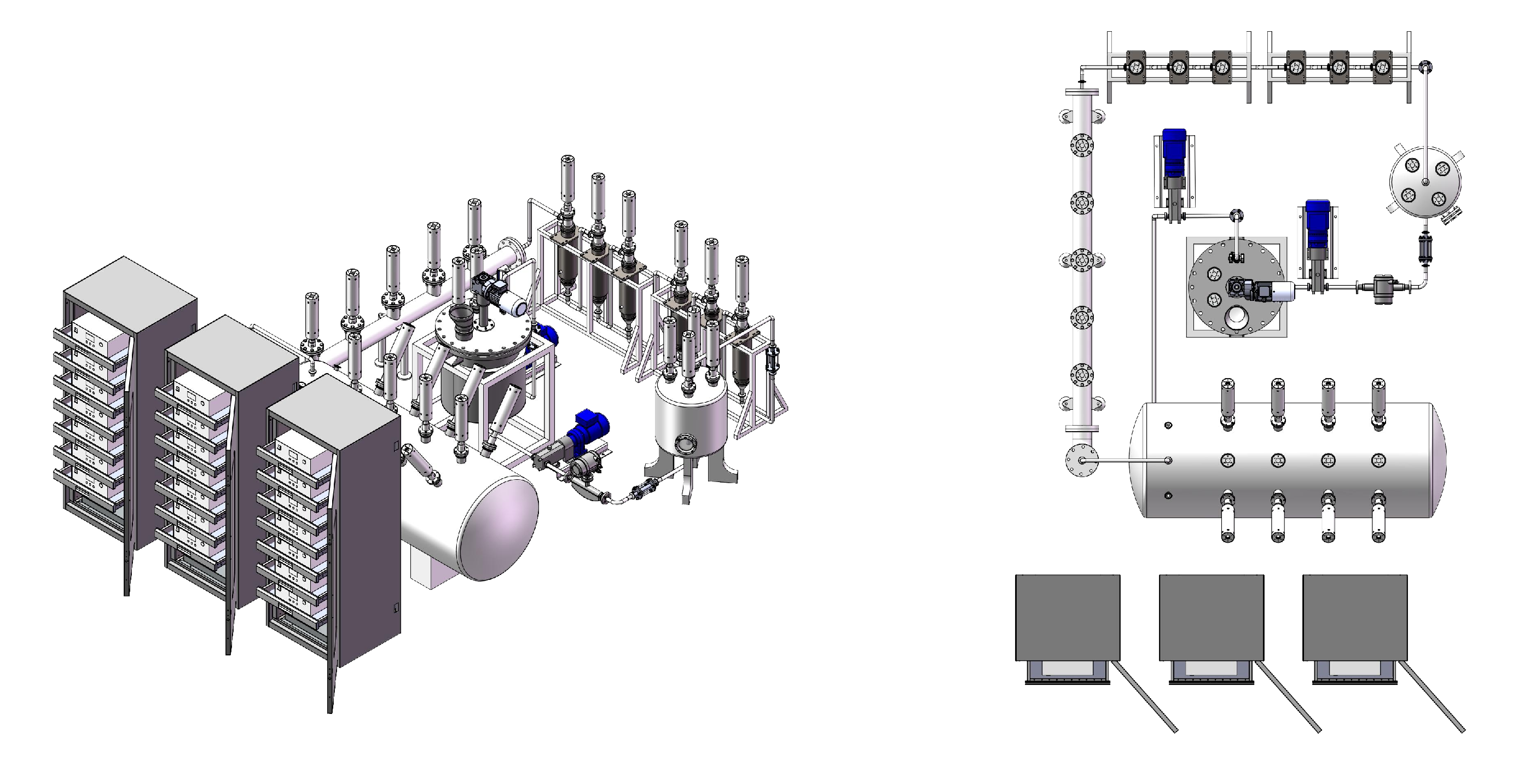

100L SS316 Tank Ultrasonic Homogenizer Pilot-plant Test Machine with Flow Cell for Herbal Powder Extraction

A homogenizer is a class of mixing devices, which is designed to break particles, both solid and liquid, into a uniform mixture. Homogenizers are available as laboratory, bench-top and industrial equipment used for various applications in research and industry. Typical application of homogenizer include the mixing and disintegration of various materials, including particles, pigments, chemicals, plants, food, cells, tissues, amongst others.

Two liquids can form diff erent types of emulsions, for example, oil and water. First, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersion medium. Second, they can form water-in-oil emulsions, where water is the dispersed phase and oil is the continuous phase. It is also possible to form multiple emulsions, including "water-in-oil-in-water" emulsions and "oil-in-water-in-oil" emulsions.

erent types of emulsions, for example, oil and water. First, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersion medium. Second, they can form water-in-oil emulsions, where water is the dispersed phase and oil is the continuous phase. It is also possible to form multiple emulsions, including "water-in-oil-in-water" emulsions and "oil-in-water-in-oil" emulsions.

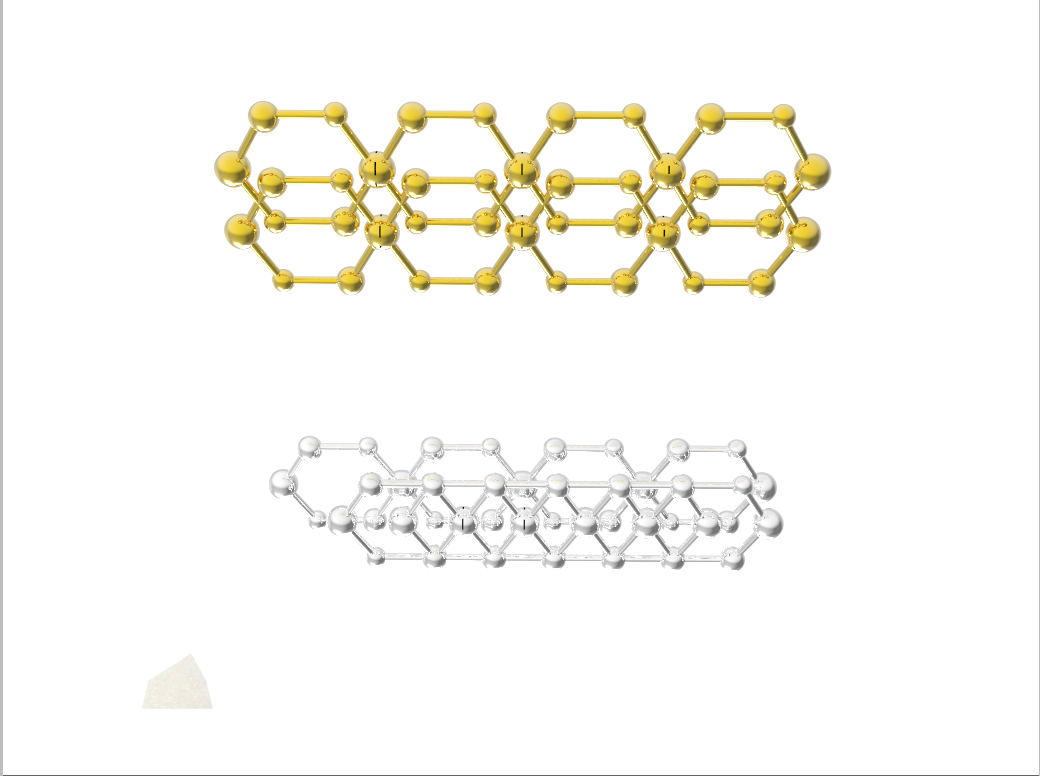

Phacoemulsification is caused by cavitation. Ultrasound passing through the liquid causes it to continuously compress and expand. High-intensity ultrasound provides the energy needed to disperse the liquid phase. When the maximum pressure is reached, the liquid ruptures at the point where the cohesion is weak. After this rupture, overpressure appeared at the point where the rupture occurred, and some cavities were found. In these cavities, the liquid dissolved gas explodes in the form of bubbles after a short time.

Parameter

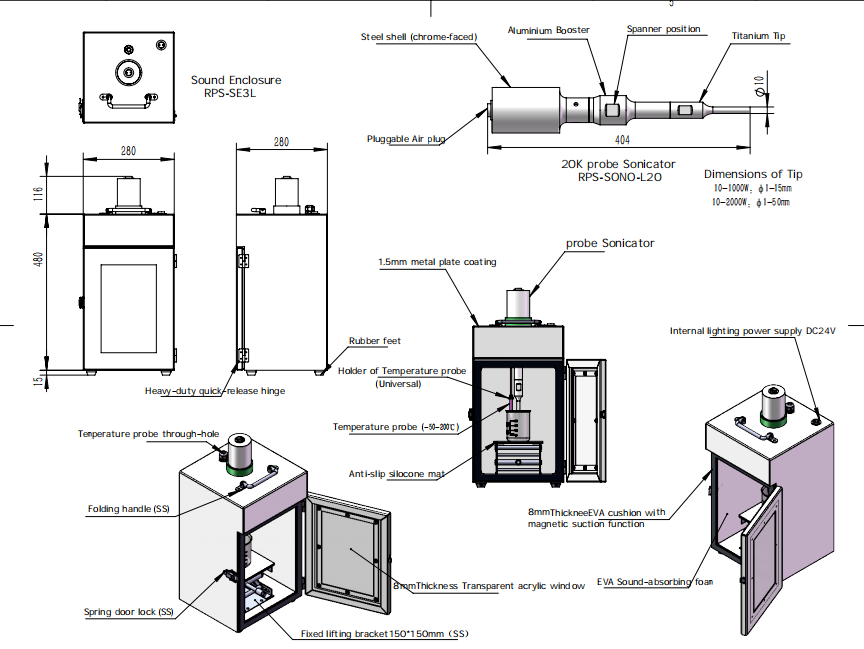

| Model | RPS-SONO-3000 |

| Frequency | 20KHZ |

| Power | 3000W |

| Input Voltage | 110 or 220V,50-60HZ |

| Temperature | 300℃ |

| Maxi Capacity | 100L/MIN with one set ultrasonic |

| Horn diameter | 35-50mm |

| Horn material | Titanium alloy/nickel-based alloy |

| Horn Length | Can be customized as your request |

| Tank layer | 1-2 layer |

| Radiation Amplitude | 20-80μm |

| Pump Volume | 0~12000ml/min., optional |

| Pressure | 35Mpa |

| Application Direction | extraction, dispersion, emulsification, defoaming, degassing, mixing |

Basic Process Flow:

Raw material pretreatment (washing, drying, pulverizing) → Mixing with solvent (water, ethanol, etc.) → Ultrasonic treatment (setting temperature, power, time) → Filtration/Separation → Concentration → Purification (optional) → Finished Product (Extract)

Key Influencing Factors:

Ultrasonic Parameters:

Power/Intensity: Higher power results in stronger cavitation, but excessive power may damage components.

Frequency: Low frequency (20-40kHz) has a strong cavitation effect, suitable for hard materials; high frequency (>100kHz) is gentler, suitable for fine extraction.

Time: Increased time increases yield, but there is an optimal value; excessive time may be ineffective or lead to degradation.

Mode: Pulsed ultrasound reduces thermal effects more effectively than continuous ultrasound.

Raw Material Factors:

Particle Size: Finer particles result in a larger contact area, but excessively fine particles may cause filtration difficulties.

Moisture Content and Structure.

Solvent Factors:

Type of Solvent (polarity matching the target component), concentration (e.g., ethanol concentration), liquid-to-solid ratio (the ratio of solvent to material).

Temperature: Typically controlled between room temperature and 60°C to balance extraction efficiency and protect against heat sensitivity.

Application

Pharmaceuticals and Health Products: Extraction of active ingredients from herbs, such as flavonoids, saponins, and alkaloids.

Food Industry: Extraction of natural pigments, flavor substances, antioxidants, and functional components.

Cosmetics: Extraction of plant essential oils, whitening, anti-inflammatory, and moisturizing active ingredients.

Natural Fragrances: Extraction of aromatic components.

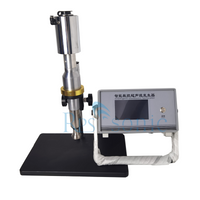

anti-explosion ultrasonic sonotrode

ultrasonic pilot plant test machine

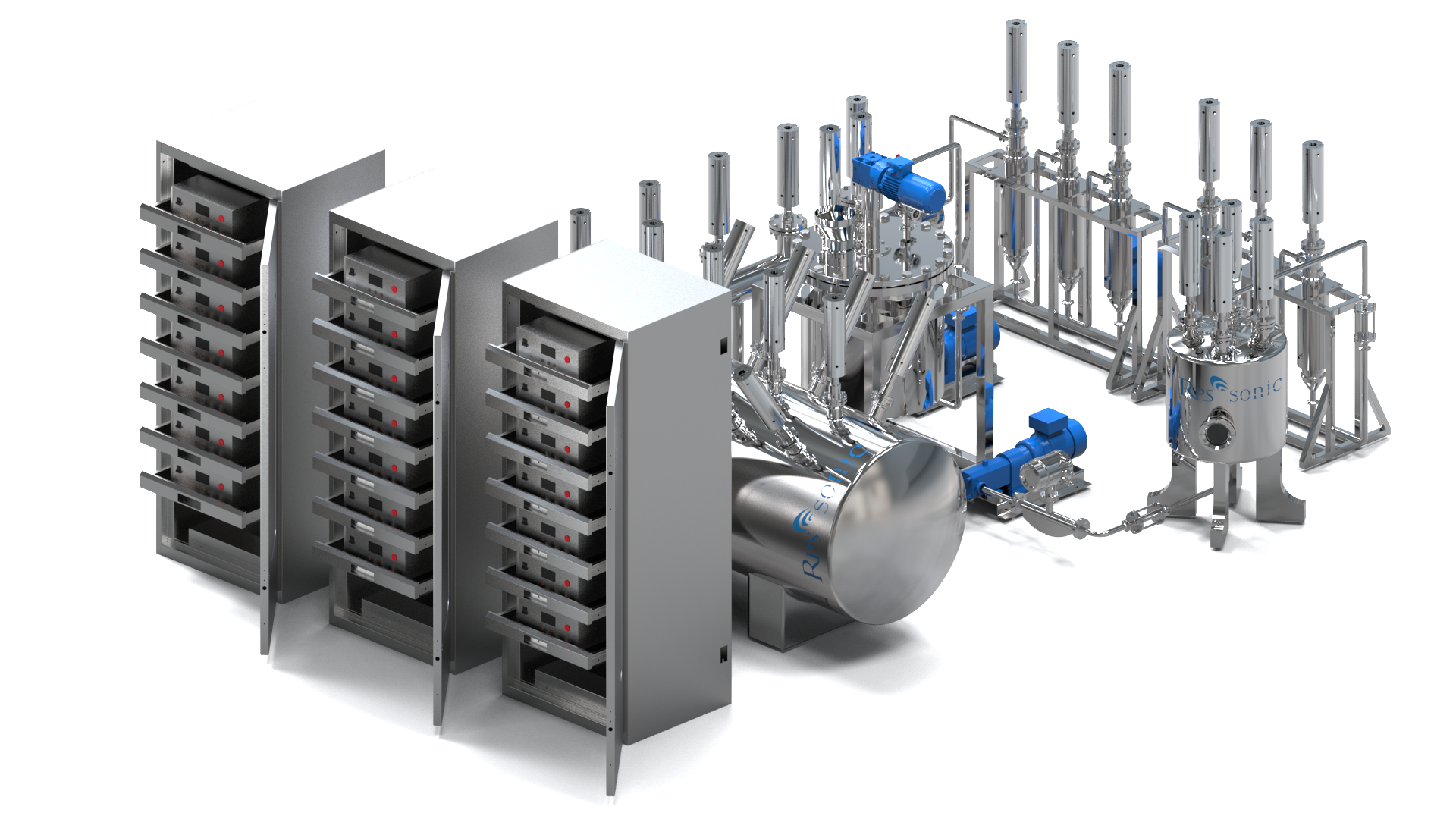

4 into 1 ultrasonic homogenizer system

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Famous Customers