Description:

Ultrasonic emulsification machine uses physical technology to generate a series of conditions close to high energy in the medium of chemical reaction. This energy can not only stimulate or promote many chemical reactions, increase the speed of chemical reactions, but also change the direction of chemical reactions and produce some effects. Ultrasonic slurry emulsifier can be applied to almost all chemical reactions, such as extraction and separation, synthesis and degradation, biodiesel production, treatment of microorganisms, degradation of toxic organic pollutants, biodegradation treatment, biological pulverization, emulsification and coagulation, powder materials The emulsification of liquid materials, such as the full stirring and emulsification of oil-water liquids, allows the main components of lithium batteries to be homogeneously emulsified into the liquid medium, and so on.

Ultrasonic emulsifier is an emulsification equipment that mixes oil and water evenly. There are three main types of emulsifiers: emulsification mixer, colloid mill and homogenizer. The type, structure and performance of the emulsifier have a great relationship with the size (dispersibility) of the emulsion particles and the quality (stability) of the emulsion. For example, the agitating emulsifier widely used in cosmetic factories has poor dispersibility of the prepared emulsion. The particles are large and rough, less stable, and more prone to contamination. However, its manufacture is simple and the price is cheap. As long as you choose a reasonable structure of the machine and use it properly, it can also produce popular cosmetics with general composite quality requirements. Colloid mills and homogenizers are good emulsification equipment. The emulsification machinery has made great progress, such as the dispersion and stability of the emulsion prepared by the vacuum emulsifier.

Specifications:

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity

(L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy

|

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

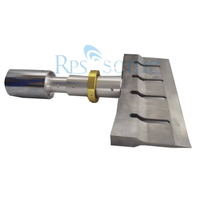

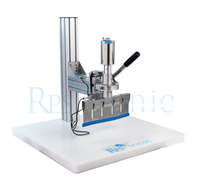

Ultrasonic emulsifiers can consist of one or more high-kilowatt ultrasonic processors, effectively providing the ability to convert laboratory applications to industrial production, achieving results comparable to today's high pressure homogenizers for continuous flow or batch production. Finely dispersed emulsion. Ultrasonic emulsifier is a technology that uses strong ultrasonic waves to pulverize insoluble solids in liquids into particles and fully mix them with surrounding liquids to form emulsions. It consists of two parts: ultrasonic emulsification part and ultrasonic drive system.

English

English