Ultrasonic Homogenizer Pilot Machine

The device is suitable for test before developing and performing scale producing.

It has 20 kHz working frequency with adjustable power range between 0-300 W.

How the Ultrasonic Homogenizer Works

The ultrasonic power supply (generator) converts 50/60 Hz voltage to high frequency electrical energy. This alternating voltage is applied to disc-shaped ceramic piezoelectric crystals within the converter, causing them to expand and contract with each change of polarity.

These longitudinal vibrations are amplified by the probe (horn) and transmitted into the liquid as ultrasonic waves consisting of alternate expansions and compressions. The pressure fluctuations pull the liquid molecules apart creating micro-bubbles (cavities), which expand during the negative pressure excursions, and implode violently during the positive excursions.

As the bubbles collapse, millions of shock waves eddies and extremes in pressures and temperatures are generated at the implosion sites. Although this phenomenon, known as cavitation, lasts but a few microseconds, and the amount of energy released by each individual bubble is minimal, the cumulative amount of energy generated is extremely high.

The high shear energy delivered is at maximum near the tip of the probe, and decreases as the distance away from the tip increases.

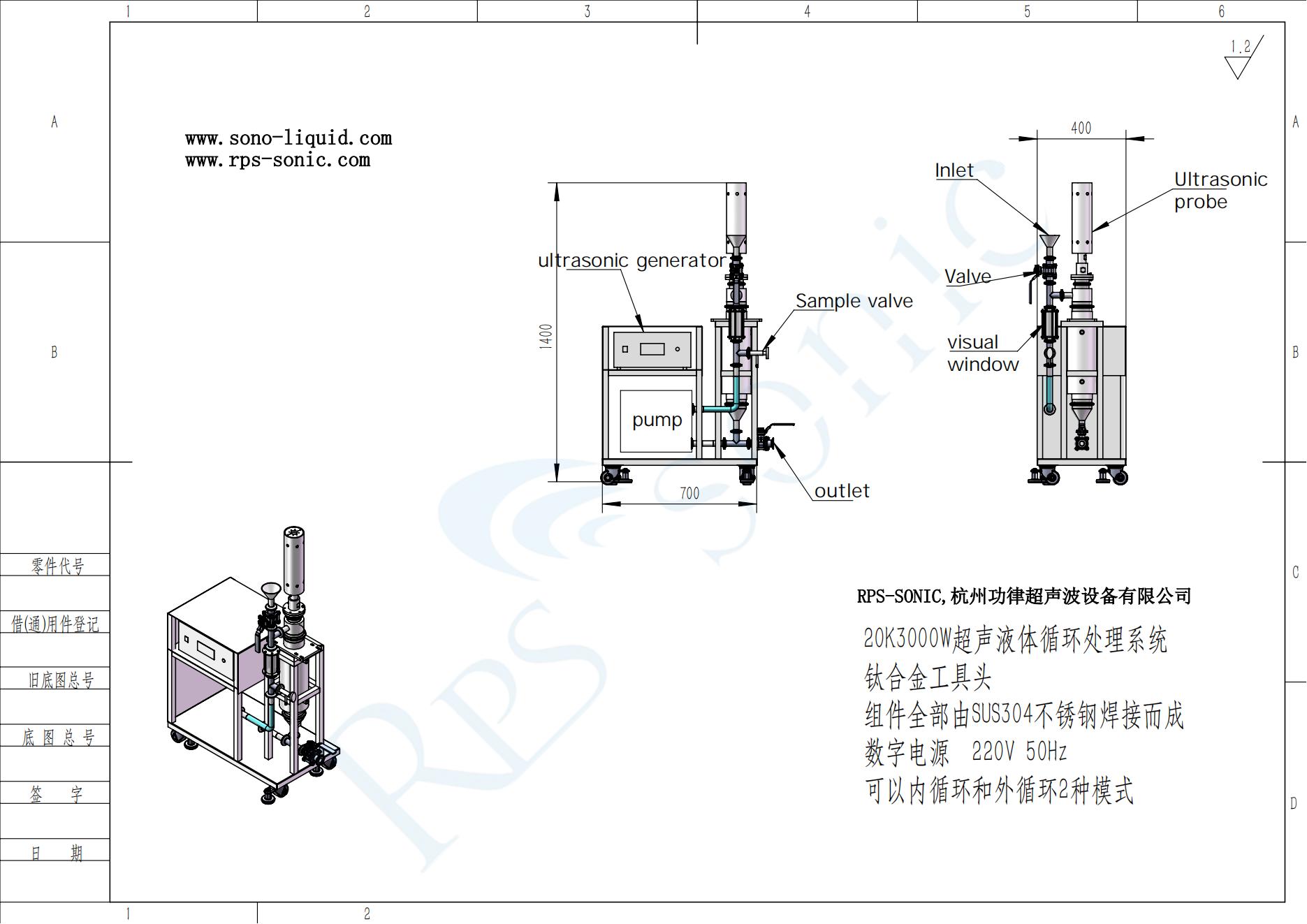

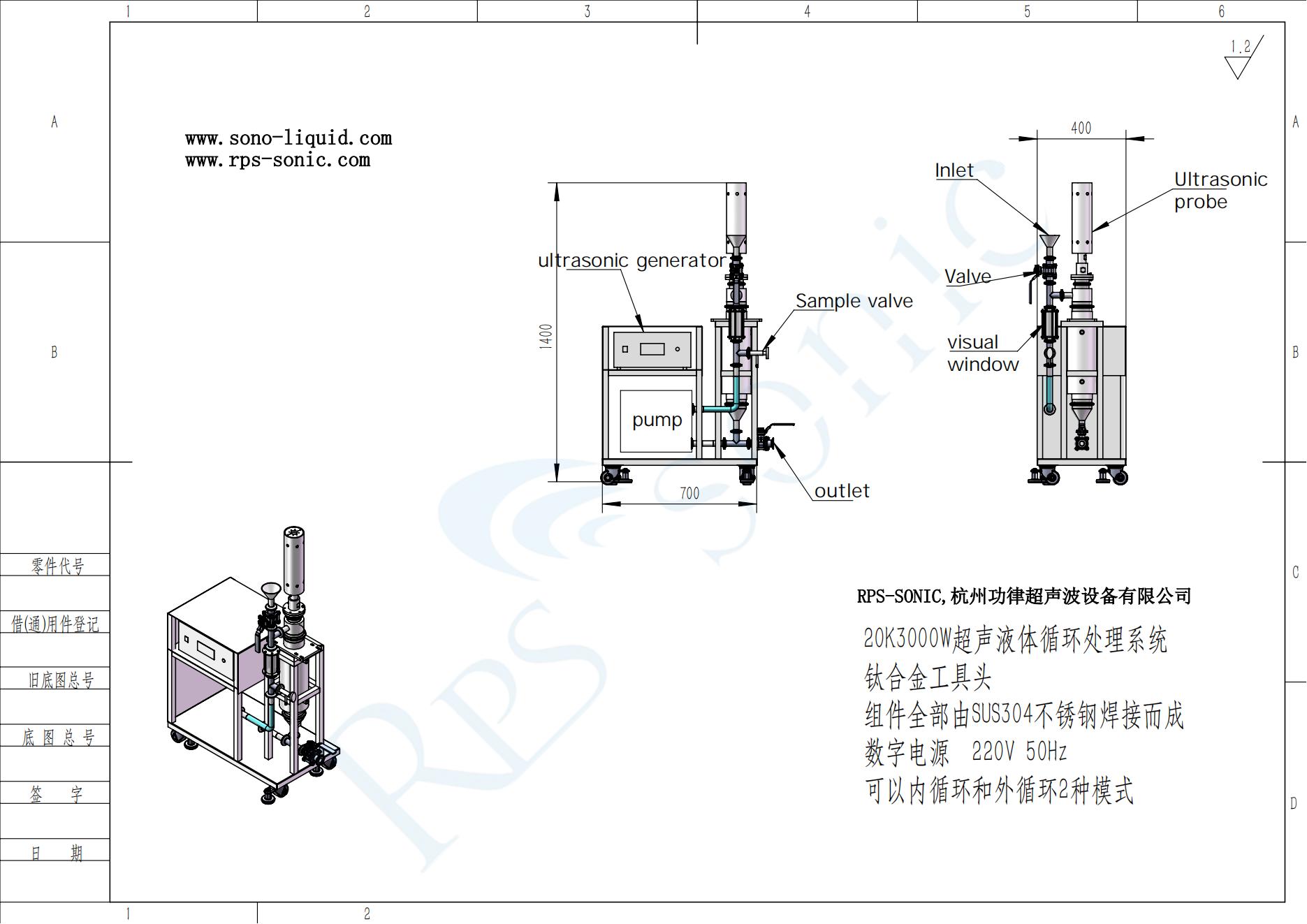

Specifications: | Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity

(L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy

|

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Applications:

Food processing

Reaction Acceleration - cavitation accelerates chemical and physical reactions.

Fine Particle Dispersion - e.g. nanoparticle processing

Disruption and Cell Lysing - will break open biological tissues and cells to extract enzymes and DNA, prepare vaccines.

Ultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

Homogenization - making uniform mixtures of liquids or liquid suspensions.

Emulsification - processing foods, pharmaceuticals, and cosmetics.

Dissolution - dissolving solids in solvents.

Degassing - removing gases from solutions without heat or vacuum.

Inline pipe cleaning, removes scale or build/up without disassembly.

Cylindrical 360° internally radiating chamber.

Compared to mechanical homogenizers, ultrasonic processing is fast and highly reproducible.

Probes are practically self cleaning, and by virtue of their design, account for negligible sample losses. When used with environmentally safe aqueous cleaning solutions, the Homogenizer becomes a powerful cleaning tool, capable of removing the most tenacious contaminants from normally inaccessible locations. Unlike ultrasonic baths, which dissipate the vibrational energy over a large area, the Homogenizer probe focuses the energy to create a concentrated, high intensity cleaning zone.