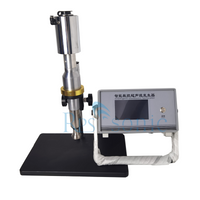

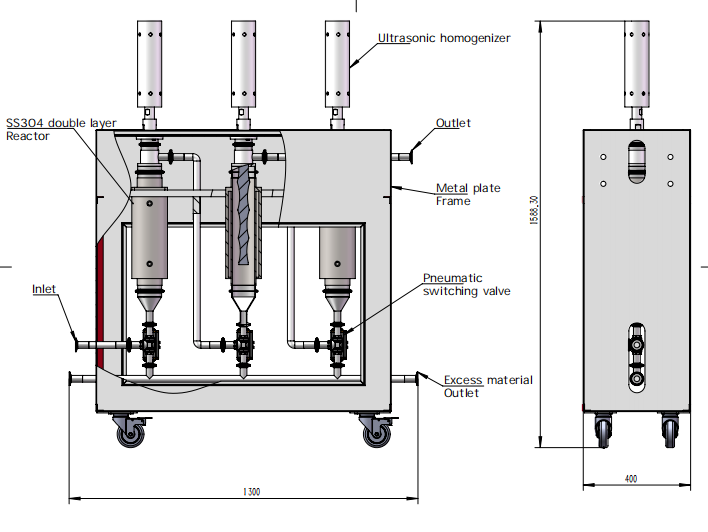

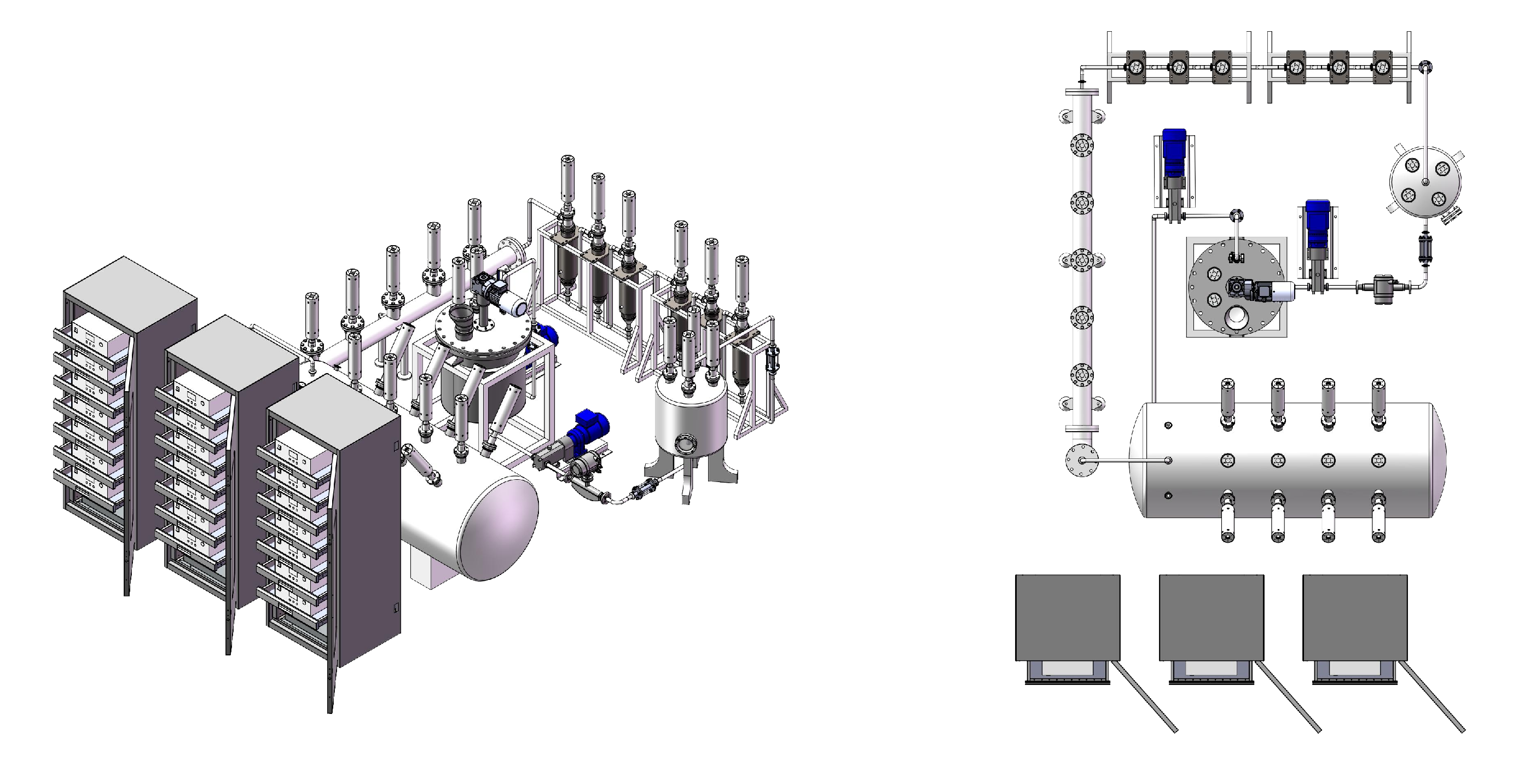

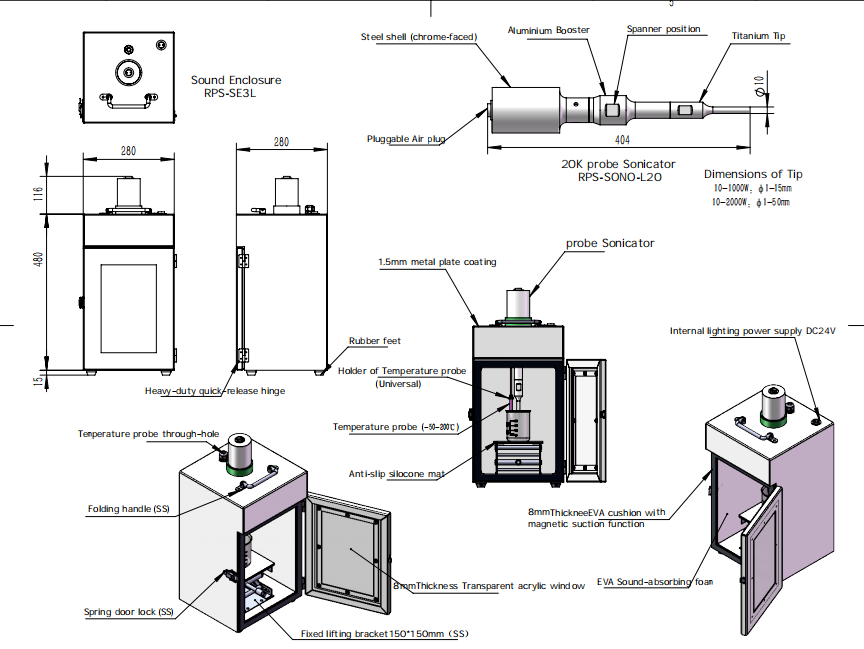

Intelligent Temperature-controlled Ultrasonic Cavitation Equipment Ultrasonic Homogenizer Testing Machine

Ultrasonic cavitation equipment is a device that uses the ultrasonic cavitation effect to operate. It uses high-frequency ultrasonic vibrations (usually between 20 kHz and 1 MHz) to produce drastic alternations of high and low pressures in the liquid, thereby triggering the rapid generation, expansion and violent rupture of cavitation bubbles. This process releases huge energy and can be applied to a variety of industrial and scientific scenarios.

Working principle

Cavitation effect: Generating tiny bubbles in liquids through high-frequency ultrasonic waves (typically 20-40 KHZ) Bubble rupture: Bubbles rapidly expand and collapse under pressure changes, generating local high temperature and high pressure Shock wave: When bubbles burst, they generate powerful micro-jets and shock waves

Main application fields

Industrial cleaning: precision parts, electronic components, optical lenses, etc

Medical field: Disinfection of medical devices, cleaning of dental instruments

Laboratory: Sample pretreatment, cell disruption

Surface treatment: Remove the surface oxide layer and polish

Parameter

Model | RPS-SONO20-50L |

Input voltage | 220/380V,50/60Hz |

Controller | Digital controller with automatic frequency tracking |

Rated power(kW) | 3.0 |

Power adjust | 20%~100% |

Amplitude | 30~80μm |

Frequency(kHz) | 20±0.5,automatic frequency tracking |

Horn material | Titanium alloy |

Horn diameter | 40~50mm |

Horn length | 440~548mm |

Flange | Tri-clamp/DN50 flange/customized flange |

Temperature control | Temperature control jacket for external temperature control system |

Tank material | Acrylic/SUS304L/SUS316L |

Processing volume | 200m-500mL,can be customized |

Blender speed | 0~800rpm,optional |

Operating method | Touch screen or buttons |

Working temperature | ≤200℃ |

Working pressure | ≤0.4MPa,can be customized |

Advantages

●Non-contact processing: avoid physical damage.

●Efficient and energy-saving: cavitation effect concentrates energy and reduces consumables.

●Environmental protection: reduce the use of chemical cleaning agents.

●Fine operation: suitable for micron/nano-level processing.

Famous Customers