High Amplitude Ultrasonic Homogenizer with Mechanical Stirring

for Emulsification And Dispersion

Ultrasonic homogenizers, also known as ultrasonic disruptors or sonicators, are widely used laboratory devices that utilize high-frequency sound waves to effectively disrupt and homogenize samples. They have revolutionized various fields of research and industrial processes, offering a reliable and efficient method for sample preparation, emulsification, dispersion, and cell lysis.

Sample Preparation in Scientific Research:

In scientific research, sample preparation is a crucial step for obtaining accurate and reliable results. Ultrasonic homogenizers provide researchers with a powerful tool for sample preparation across various disciplines. They excel in the extraction of DNA, RNA, proteins, and other biomolecules from different types of biological samples. By subjecting the samples to intense ultrasonic vibrations, the homogenizer breaks down cell walls and releases the desired molecules, ensuring high yields and preserving sample integrity.

Emulsification and Dispersion:

Ultrasonic homogenizers are widely employed in the food, pharmaceutical, and cosmetic industries for emulsification and dispersion processes. They can efficiently mix immiscible liquids, such as oil and water, to create stable and uniform emulsions. The ultrasonic waves create intense cavitation and microstreaming, which disrupts larger droplets into smaller ones, resulting in a fine and consistent mixture. This capability is invaluable in the production of creams, lotions, suspensions, and various formulations.

Parameter

Application

Ultrasonic homogenizers find extensive usage in industrial processes beyond the laboratory. They are employed in the production of paints, coatings, and inks to achieve uniform particle size distribution and enhanced stability. Additionally, they are utilized in the manufacturing of nanoparticles, where precise control over particle size and distribution is crucial. Ultrasonic homogenizers are also valuable in the production of various pharmaceutical formulations, where consistent and efficient mixing is essential to ensure product quality.

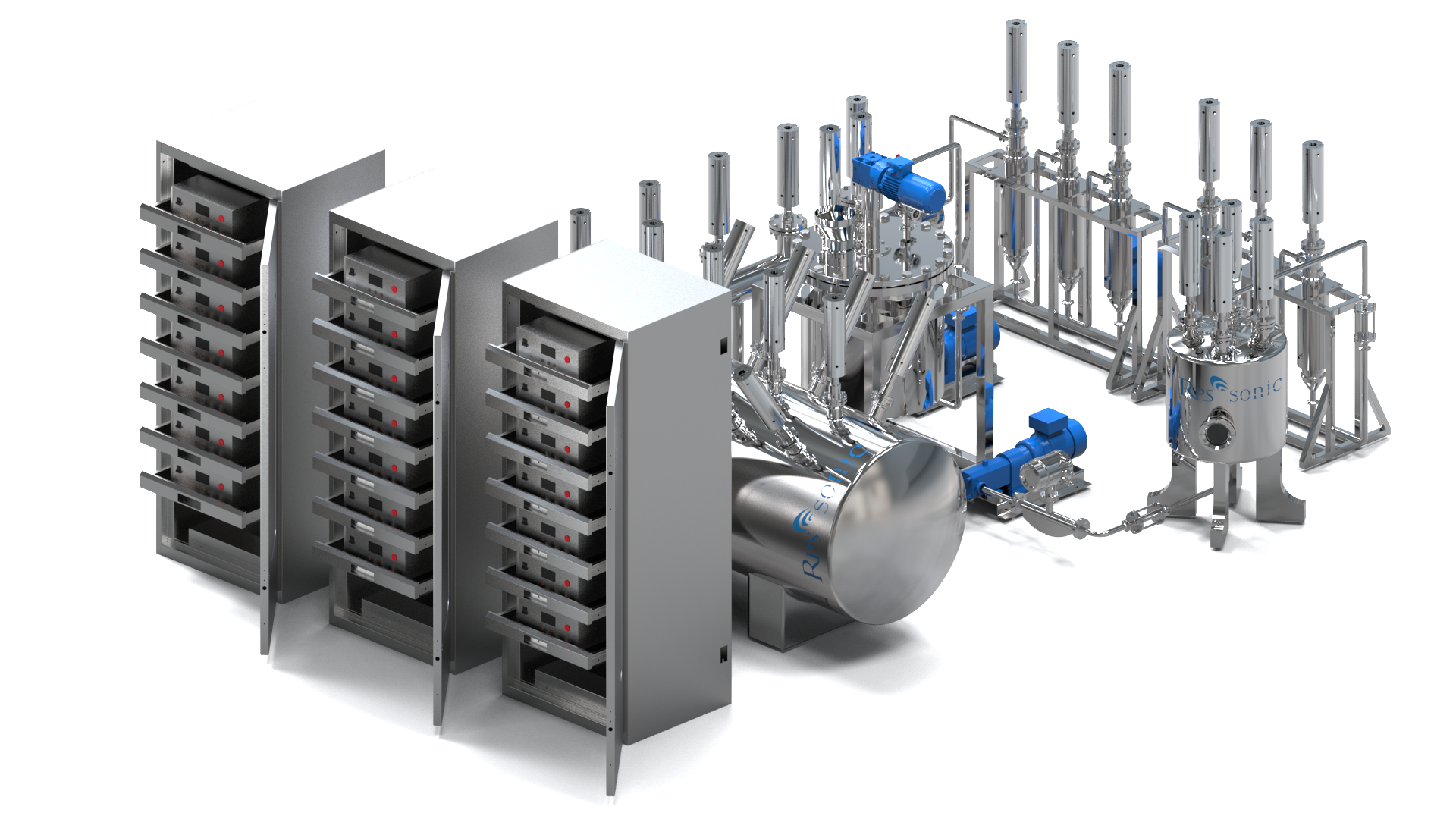

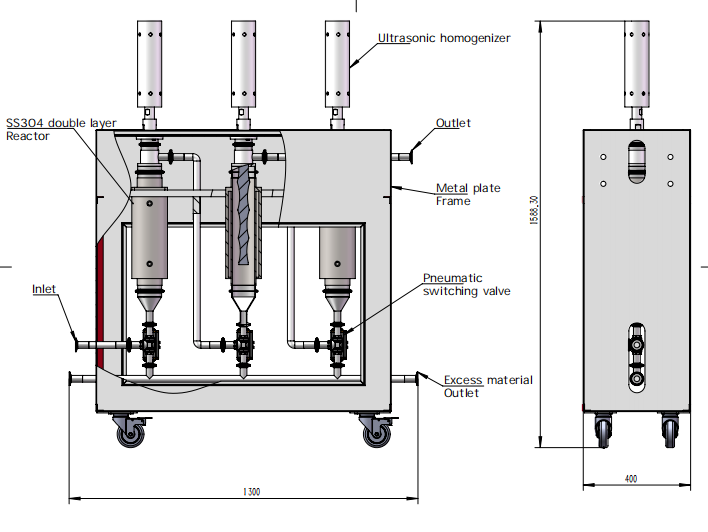

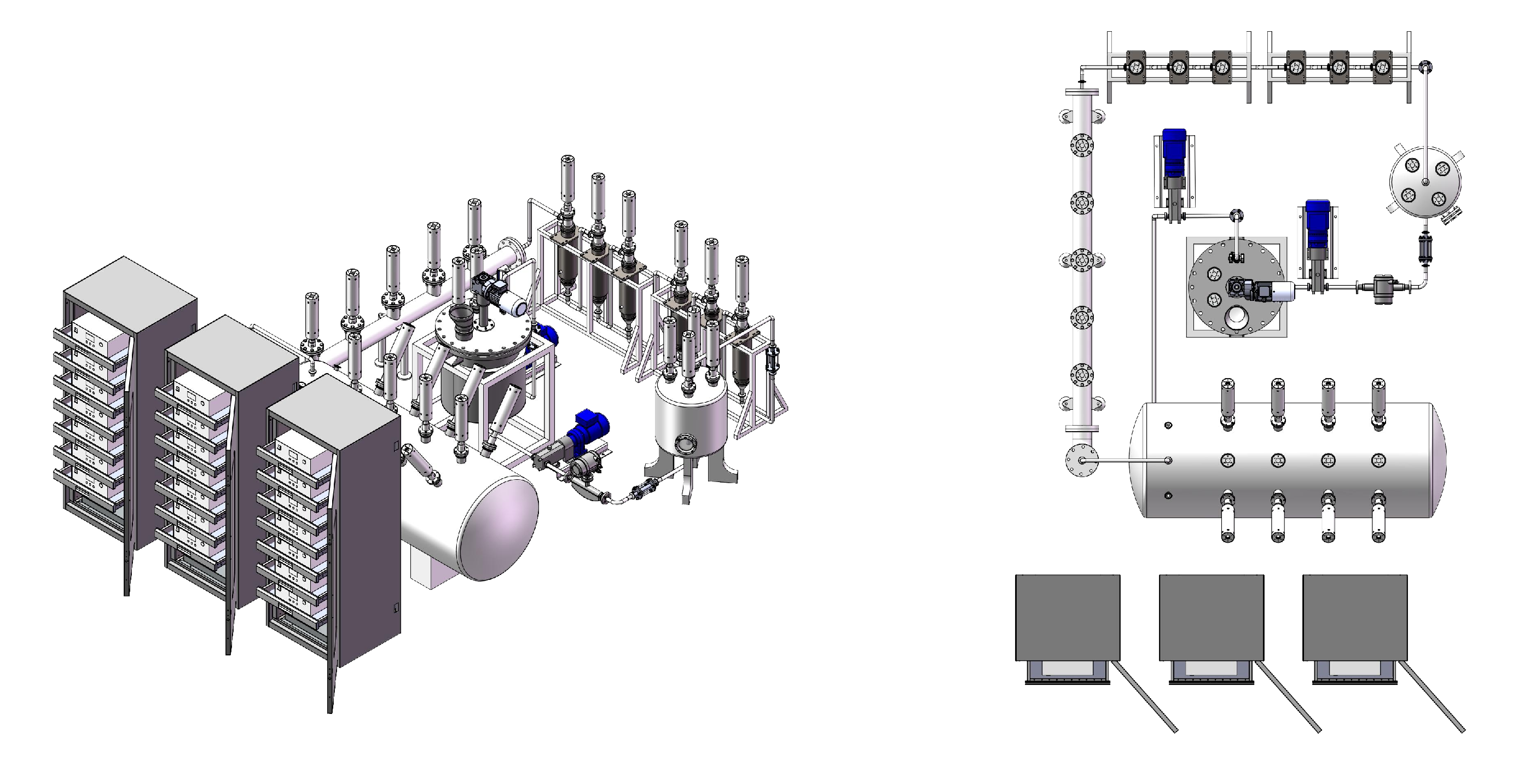

anti-explosion ultrasonic sonotrode

ultrasonic pilot plant test machine

4 into 1 ultrasonic homogenizer system

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Famous Customers

![C]LLCKM6_7%(R[{`{6_D]7U](http://iirorwxhjionlo5p.ldycdn.com/cloud/npBpqKrrRlkSoioppkjpj/C-LLCKM6_7-R-6_D-7U.png)