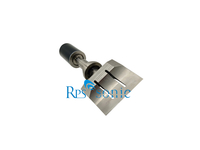

20khz Ultrasonic Cutting System One-piece Construction Blade for Automated Machinery

What's the principle of ultrasonic cutting?

The principle of an ultrasonic cutter is completely different from conventional one. It uses the energy of ultrasonic to melt the material to be cut. Therefore, the ultrasonic cutting does not require a sharp cutting edge, nor does it require a large pressure, and does not cause any chipping or breakage. At the same time, since the cutting blade is subjected to ultrasonic vibration, the frictional resistance is particularly small, and the material to be cut is not easily adhered to the blade. This is particularly effective for cutting viscous and elastic materials, frozen materials such as food, rubber, etc., or objects that are inconvenient to apply pressure.

The basic structure of the ultrasonic cutting machine is an ultrasonic transducer, a horn, a cutting blade (tool head), and generator. The ultrasonic generator converts the commercial power into a high-frequency high-voltage alternating current and transmits it to the ultrasonic transducer. An ultrasonic transducer is actually equivalent to an energy conversion device that converts input electrical energy into mechanical energy, ie, ultrasonic waves. Its manifestation is that the transducer moves back and forth in the longitudinal direction. The frequency of the telescopic motion is equivalent to the frequency of the high frequency alternating current supplied by the driving power source. The role of the horn is to fix the entire ultrasonic vibration system and to amplify the output amplitude of the transducer. The cutting blade (tool head) further enlarges the amplitude on the one hand and focuses the ultrasonic wave. On the other hand, the ultrasonic wave is output, and the ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by using a similar cutting edge of the cutting blade. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. At this time, as long as a small cutting force is applied, the purpose of cutting the material can be achieved.

Similar to conventional cutting, the basic components required are a cutter and an anvil, and the ultrasonic cutter has two basic structures. Depending on the location of the ultrasonic application, we may wish to divide it into an ultrasonic cutter cutter and an ultrasonic cutter cutter.

Introduction:

The sharpness of an ultrasonic cutter differs according to various combinations of oscillator, transducer, and blade. Because of abundant experience, our company prepares combinations suitable for various materials. Since we can select the model most suitable for your cutting work, we ask that you confirm the sharpness of the selected model by test cutting first.

20khz Ultrasonic Cutting System One-piece Construction Blade for Automated Machinery are ideal for cutting rubber, composite aerospace materials such carbon fiber, Nomex and various honeycombs. ultrasonic cutting systems can be operated as hand-held units or incorporated into automated machinery. Our applications and design engineering team have developed industry leading tooling to meet the rugged demands of cutting applications. Solid, one-piece construction of horn blade technology virtually eliminates breakage and energy loss.

Parameter

Frequency | 20Khz |

Frequency adjustment | Auto-tracking type |

Max. power output | 1000W |

Power output | Infinitive adjustment |

Power supply | AC200V 50/60Hz |

Outer dimension (mm) | 120*120*380 |

Weight | 8kg |

Blade thickness | 1mm |

Target Materials

Resin plate

Glass fiber (GFRP)

Formed decorative film

Foam

Blow-molded parts

Injection-molded parts

Carbon fiber (CFRP)

Aluminum foil composites

Non-woven fabrics

Controlled-depth kiss cutting

BENEFITS OF ROBOTIC ULTRASONIC CUTTING

Ultrasonic Cuts are cleaner than conventional cutters with minimal debris

Large inventory of standard carbide cutting blades for all shapes and sizes of applications.

Greatly reduces “plowing” effect on materials versus mechanical cutters

Create more consistent cuts

Greatly reduce clean up

Have a wider cutting temperature range

Easily change over from product to product