20kHz Ultrasonic Metal Liquid Processing Ultrasonic Metal Melt Fusion Processing Melting

Ultrasound is a type of compressional longitudinal wave that can effectively propagate in media such as gases, liquids, solids, and molten solids, and it has strong penetrative properties. When ultrasound propagates in a liquid medium, it can transmit a significant amount of energy and generate strong impacts and cavitation effects at interfaces. Similar to sound waves, ultrasound can also exhibit phenomena such as reflection, interference, superposition, and resonance. Under the same conditions of amplitude, ultrasound has much greater intensity than ordinary sound waves. It has been applied in the metallurgical industry and has achieved certain results in industrial applications.

Ultrasonic metal melt equipment is mainly used in the metallurgical industry. Under the conditions of ultrasonic vibration, it is beneficial for degassing, impurity removal, grain refinement, and strengthening the leaching process of metal solutions. The application of ultrasonic metal melt equipment in molten metal enables the rapid composite of fibers with metals, resulting in the production of high-performance composite materials. Under the influence of ultrasound, liquid metal can infiltrate preformed particles or mix uniformly with particles. Ultrasonic plating can be used for processes such as galvanizing steel wire and aluminum plating.

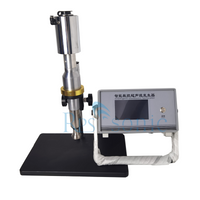

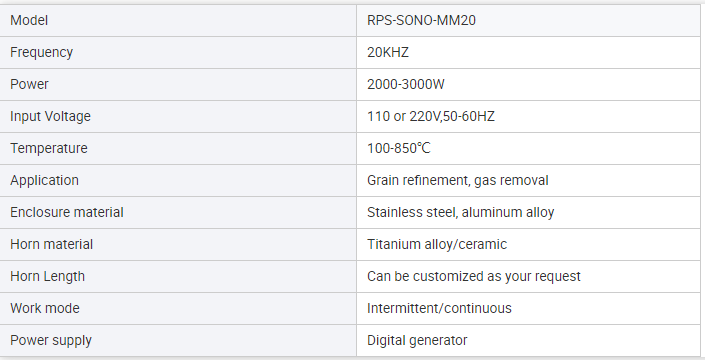

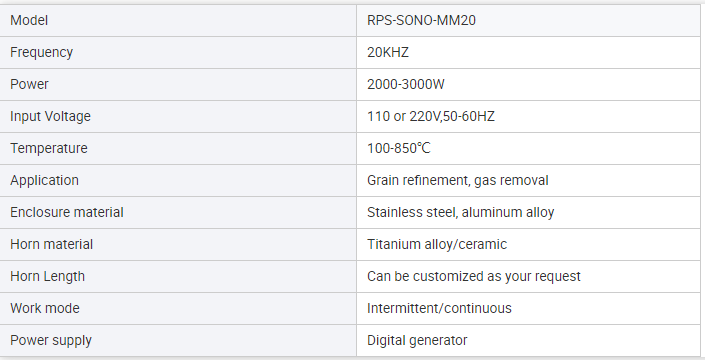

Parameter

Main Functions:

Impurity RemovalIt is challenging for small inclusions in molten steel to float to the surface, and they only become more easily removable when they accumulate. By introducing ultrasound into the solution using ultrasonic metal melt equipment, ultrasound standing waves can successfully stratify and aggregate the inclusions in the solution.

Ultrasound DegassingUltrasound plays a significant role in removing gases from molten metal. The elastic vibrations generated by ultrasound can completely degas the alloy within a few minutes. When ultrasound vibrations are introduced into the molten metal, cavitation phenomena occur due to the formation of voids caused by the rupture of the liquid phase. As a result, gases dissolved in the liquid metal concentrate in these voids. The elastic vibrations of ultrasound promote the formation of bubble nuclei and cause them to continuously grow until they reach a size suitable for easy expulsion from the molten metal.

Ultrasound-Assisted Static CastingImproving Casting Quality Ultrasonic metal melt equipment can be applied to the crystallizer to enhance the surface quality of castings. The vibrations of ultrasound on the crystallizer can be used for small ingots, large ingots, and slabs without the need for sliding. When casting small ingots and large ingots, applying ultrasonic vibration to the crystallizer can result in a smooth surface of the castings.

Grain RefinementDuring the production of castings using ultrasonic vibration solidification method, ultrasound generates alternating positive and negative sound pressure as it propagates, forming jets. Additionally, due to nonlinear effects, sound flow and micro-sound flow are generated, and ultrasonic cavitation at the solid-liquid interface produces high-speed micro-jets. The cavitation effect of ultrasound in the liquid can break and disrupt dendrites, impact the solidification front, and enhance stirring and diffusion, thereby achieving effects such as purifying the structure, refining the grains, and homogenizing the microstructure. In addition to the mechanical disruption of dendrites caused by vibration, another important effect of ultrasonic vibration solidification is the increase in the effective undercooling of the metal liquid and the reduction of the critical nucleus radius, thereby increasing the nucleation rate and refining the grains.

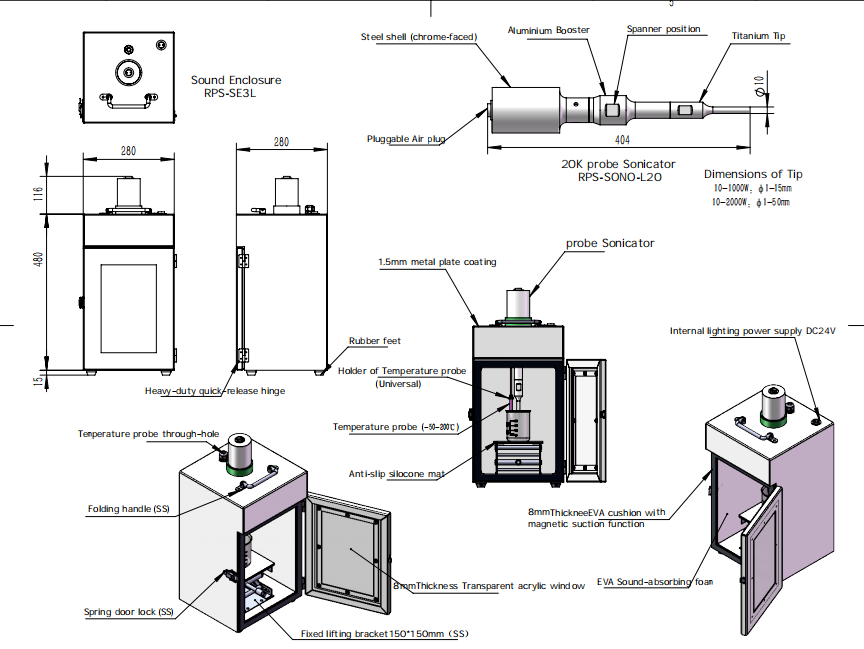

Product characteristicsHigh temperature resistance: maximum temperature 1300℃. Corrosion resistance: Use high strength titanium alloy tool heads. Remarkable effect: micromolecular interaction, the effect is direct and obvious. Easy installation: Through standard flange docking installation, there is no need to change the customer's existing production equipment and process.

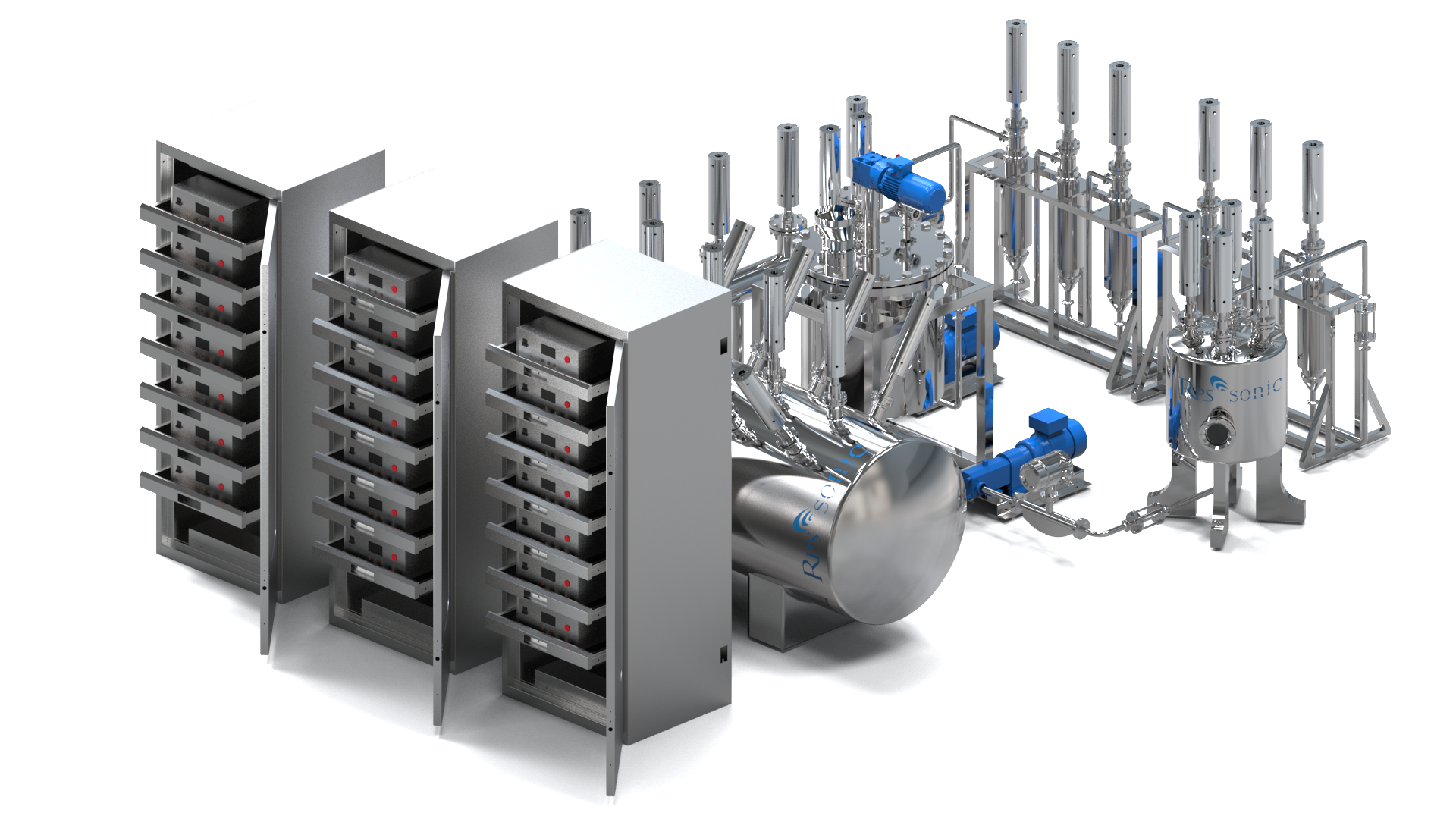

anti-explosion ultrasonic sonotrode

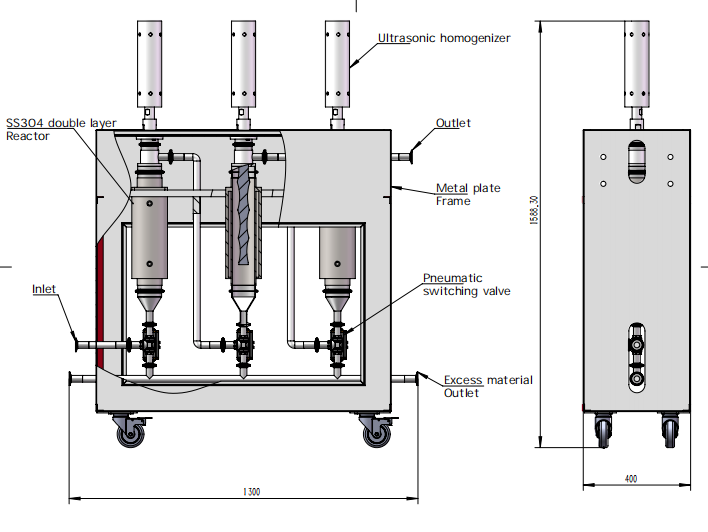

ultrasonic pilot plant test machine

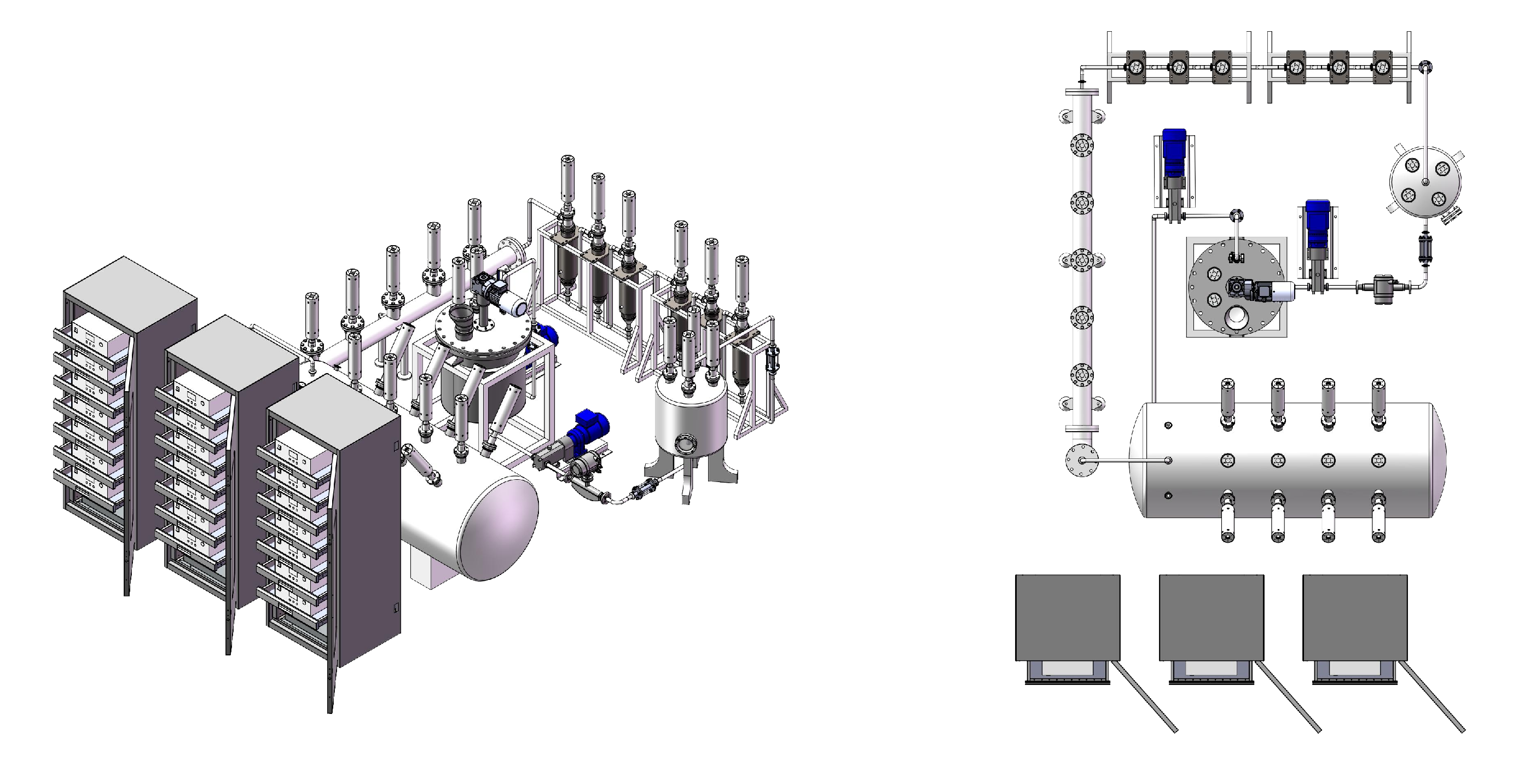

4 into 1 ultrasonic homogenizer system

Famous Customers