Ultrasonic Defoaming Equipment Break Foam Bubbles Noncontact

POWER ULTRASONICS DEFOAMING METHOD: A GREEN TECHNOLOGY

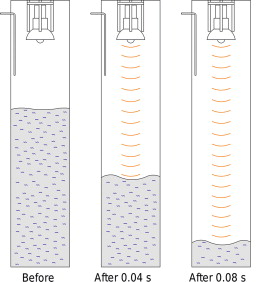

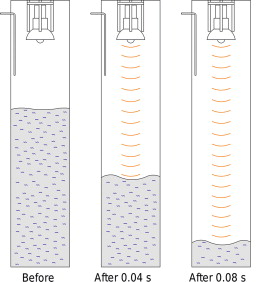

High intense ultrasonic waves are a clean and efficient procedure to break foam bubbles. The airborne ultrasonic defoamer is an electro-acoustic device capable of generating ultrasonic waves of high intensity which efficiently break foam bubbles without contaminating the treated solution. Hence, the ultrasonic system is not in direct contact with the multiphase fluid whilst in operation. The mechanism of ultrasonic defoaming is a combination of the following effects: high acoustic pressure, radiation pressure, resonance of bubbles and acoustic streaming. Other factors, such as the atomization of the bubble surface, may also contribute to foam rupture. The effectiveness of high-power ultrasonics in defoaming has been previously investigated at laboratory stage. Nevertheless, until now, there were no ultrasonic defoaming systems commercially available.

DESCRIPTION OF THE ULTRASONIC DEFOAMING SYSTEM

The technology for ultrasonic defoaming commercialised by RPS-SONIC is based on a new type of power airborne ultrasonic generator. Such a generator is constituted by a piezoelectric power transducer driving a specially designed plate radiator, and the electronics to drive and control the tuned assembly. This novel ultrasonic generator produces highly focused radiation in such a way that levels of acoustic pressure higher than 170 dB may be achieved at a focal area. The Ultrasonic Defoaming System (UDS) is a powerful and compact device which does not interfere in the process; it can be easily sterilized and fulfils industrial requirements.

Transducer general technical data: