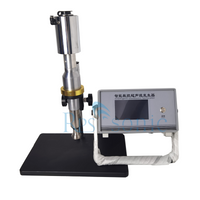

Ultrasonic Homogenizer Ultrasonic Reactor Mushroom Extraction Herbal Extraction with Flow Cell

A homogenizer is a class of mixing devices, which is designed to break particles, both solid and liquid, into a uniform mixture. Homogenizers are available as laboratory, bench-top and industrial equipment used for various applications in research and industry. Typical application of homogenizer include the mixing and disintegration of various materials, including particles, pigments, chemicals, plants, food, cells, tissues, amongst others.

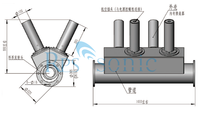

3 into 1 ultrasonic homogenizer system

Ultrasonic extraction is considered the wave of the future when it comes to the successful extraction of cannabinoids from hemp. The medicinal cannabis industry has started to turn to the advanced method as one of the best ways to obtain viable therapeutic compounds successfully from the cannabis plant fibers. It is a clean method that leaves no solvent residue.

Parameter

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Ultrasonic extraction features

It is suitable for the extraction of active ingredients of Chinese herbal medicines. It is a new method and new process for Chinese medicine pharmaceuticals to completely change the traditional method of boiling and alcohol precipitation extraction. Compared with boiling and alcohol precipitation, ultrasonic extraction has the following outstanding features:

(1) No need for high temperature. Enhanced extraction with ultrasonic waves at a water temperature of 40°C-50°C, without boiling at high temperature, does not destroy some of the medicinal ingredients in Chinese medicinal materials that are thermally unstable, easily hydrolyzed or oxidized.

(2) Atmospheric pressure extraction, good safety, simple operation and convenient maintenance.

(3) High extraction efficiency. The best extraction rate can be obtained by ultrasonic enhanced extraction for 20 to 40 minutes

(4) with broad spectrum. Wide applicability, the vast majority of Chinese herbal medicines can be ultrasonically extracted.

(5) Ultrasonic extraction has little to do with the properties (such as polarity) of the solvent and the target extract.

(6) Reduce energy consumption. Because ultrasonic extraction does not require heating or low heating temperature, the extraction time is short, so the energy consumption is greatly reduced.

(7) The processing capacity of medicinal raw materials is large, which is doubled or several times higher, and the impurities are few, and the effective components are easy to separate and purify.

Application

- Disruption of cells, bacteria, viruses, spores, fungi or tissues (cell disruption)

- Extraction of ingredients (lysis)

- Homogenization of different substances

- Production of finest emulsions with minimum droplet size

- Dissolution of poorly and poorly soluble substances in liquids

- Production of dispersions (emulsions and suspensions)

- Catalysis and acceleration of chemical reactions

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Famous customers

English

English