High Amplitude Ultrasonic Sonochemistry Machine

for Emulsification And Dispersion

Different industries have very different emulsion manufacturing processes. These differences include the components used (mixtures, including various components in the solution), emulsification methods, and more processing conditions. Emulsion is a dispersion of two or more immiscible liquids. High-intensity ultrasound is provided to disperse the liquid phase (dispersed phase) in the small droplets of another second phase (continuous phase). energy.

Two liquids can form diff erent types of emulsions, for example, oil and water. First, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersion medium. Second, they can form water-in-oil emulsions, where water is the dispersed phase and oil is the continuous phase. It is also possible to form multiple emulsions, including "water-in-oil-in-water" emulsions and "oil-in-water-in-oil" emulsions.

erent types of emulsions, for example, oil and water. First, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersion medium. Second, they can form water-in-oil emulsions, where water is the dispersed phase and oil is the continuous phase. It is also possible to form multiple emulsions, including "water-in-oil-in-water" emulsions and "oil-in-water-in-oil" emulsions.

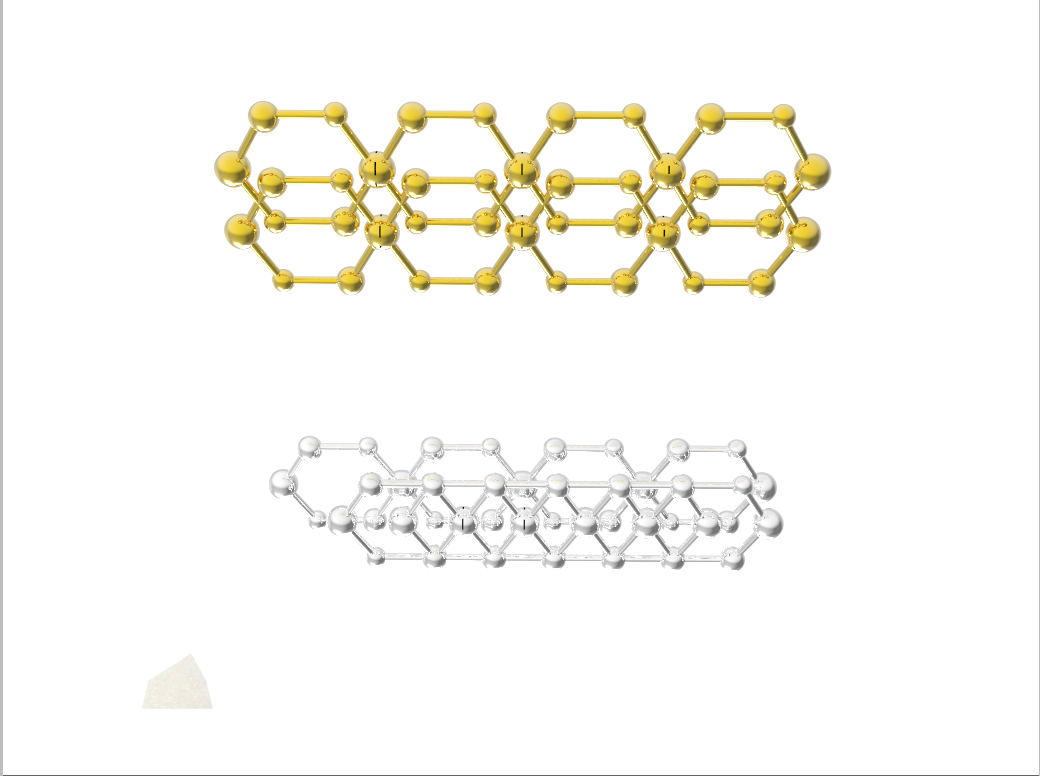

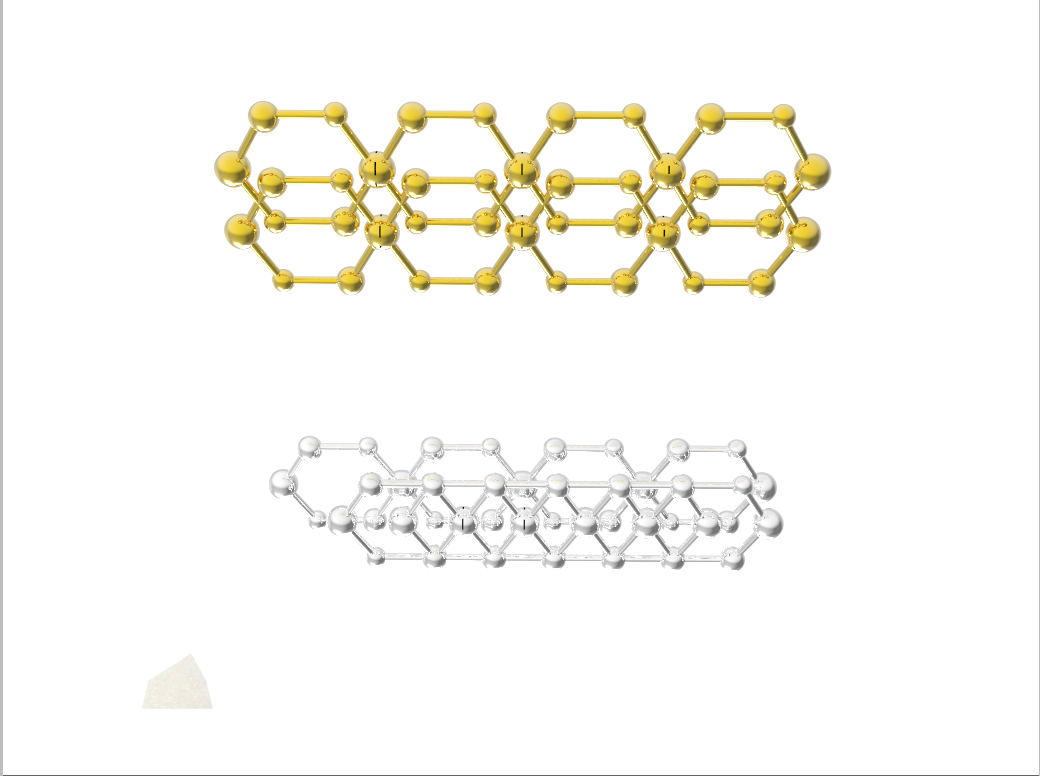

Phacoemulsification is caused by cavitation. Ultrasound passing through the liquid causes it to continuously compress and expand. High-intensity ultrasound provides the energy needed to disperse the liquid phase. When the maximum pressure is reached, the liquid ruptures at the point where the cohesion is weak. After this rupture, overpressure appeared at the point where the rupture occurred, and some cavities were found. In these cavities, the liquid dissolved gas explodes in the form of bubbles after a short time.

Parameter

Application

Ultrasonic emulsification technology has been widely used in food, paper, paint, chemical, pharmaceutical, textile, petroleum, metallurgy and other industrial fields. Ultrasonic equipment can be easily installed on existing production lines, which is convenient for manufacturers to upgrade equipment at a lower cost. Ultrasonic emulsification can also create emulsions that do not work in general methods. The commonly used mixing method can only produce 5% paraffin wax in water. It is incredible that under the action of power ultrasound, 20% paraffin wax emulsion can be produced.

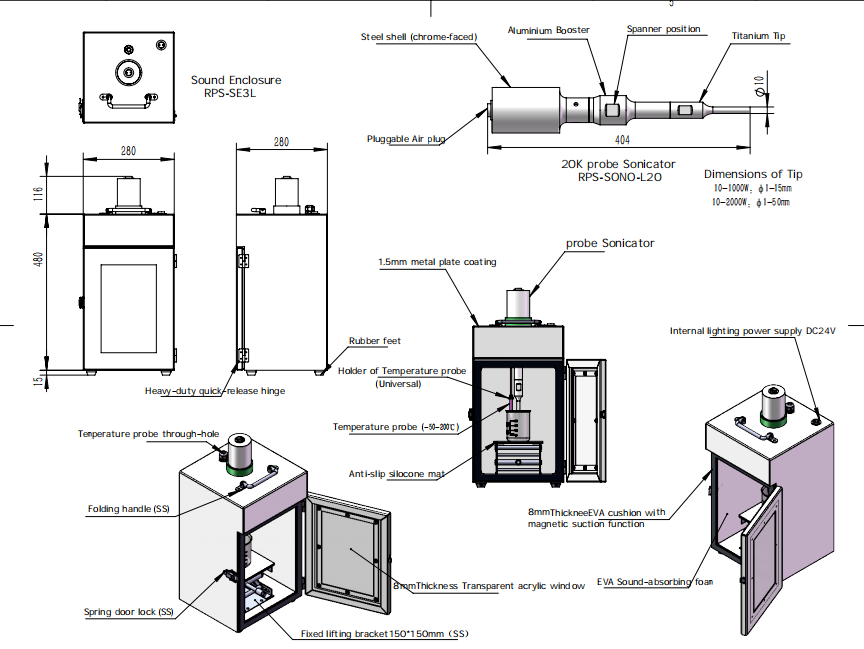

anti-explosion ultrasonic sonotrode

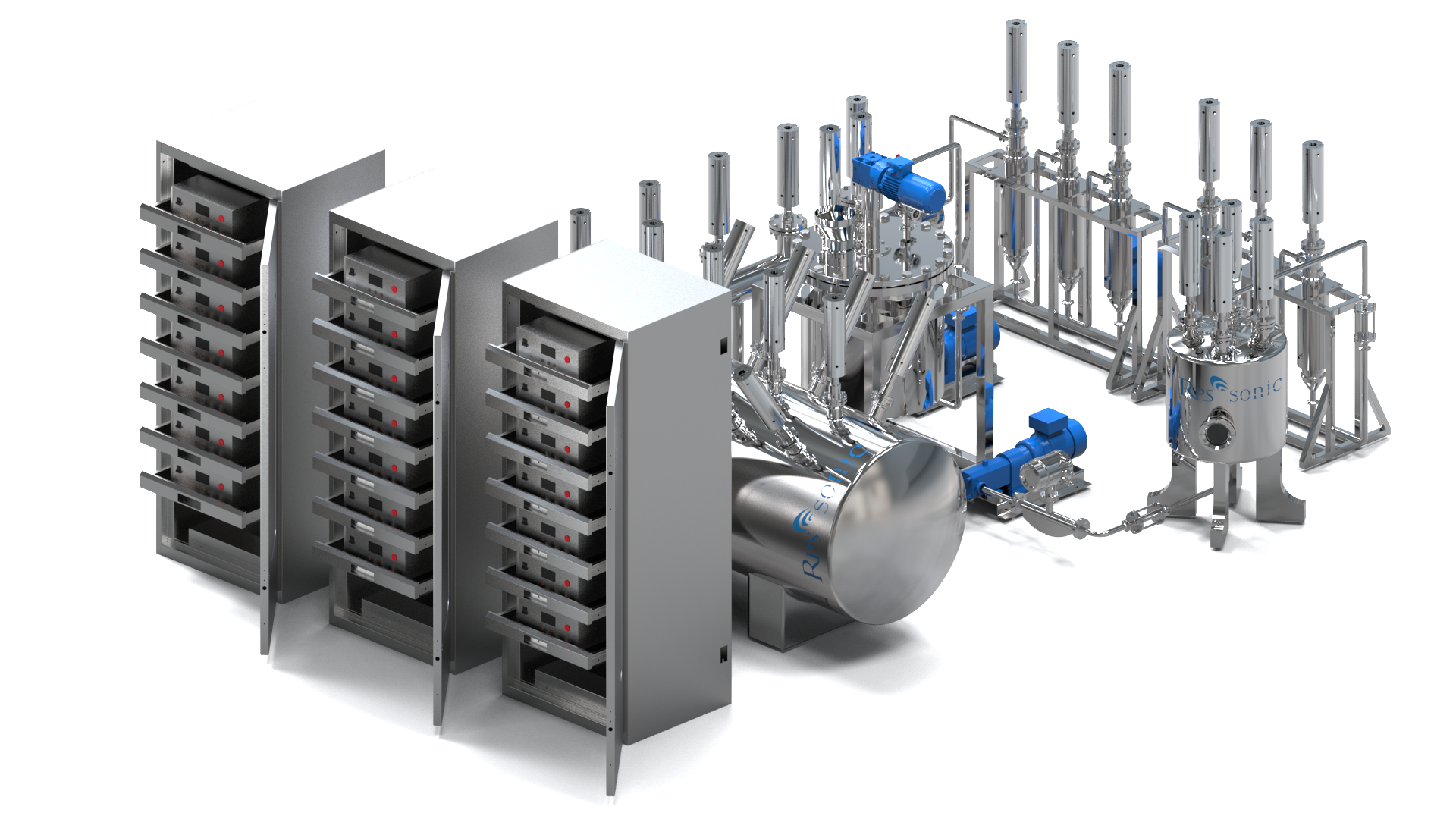

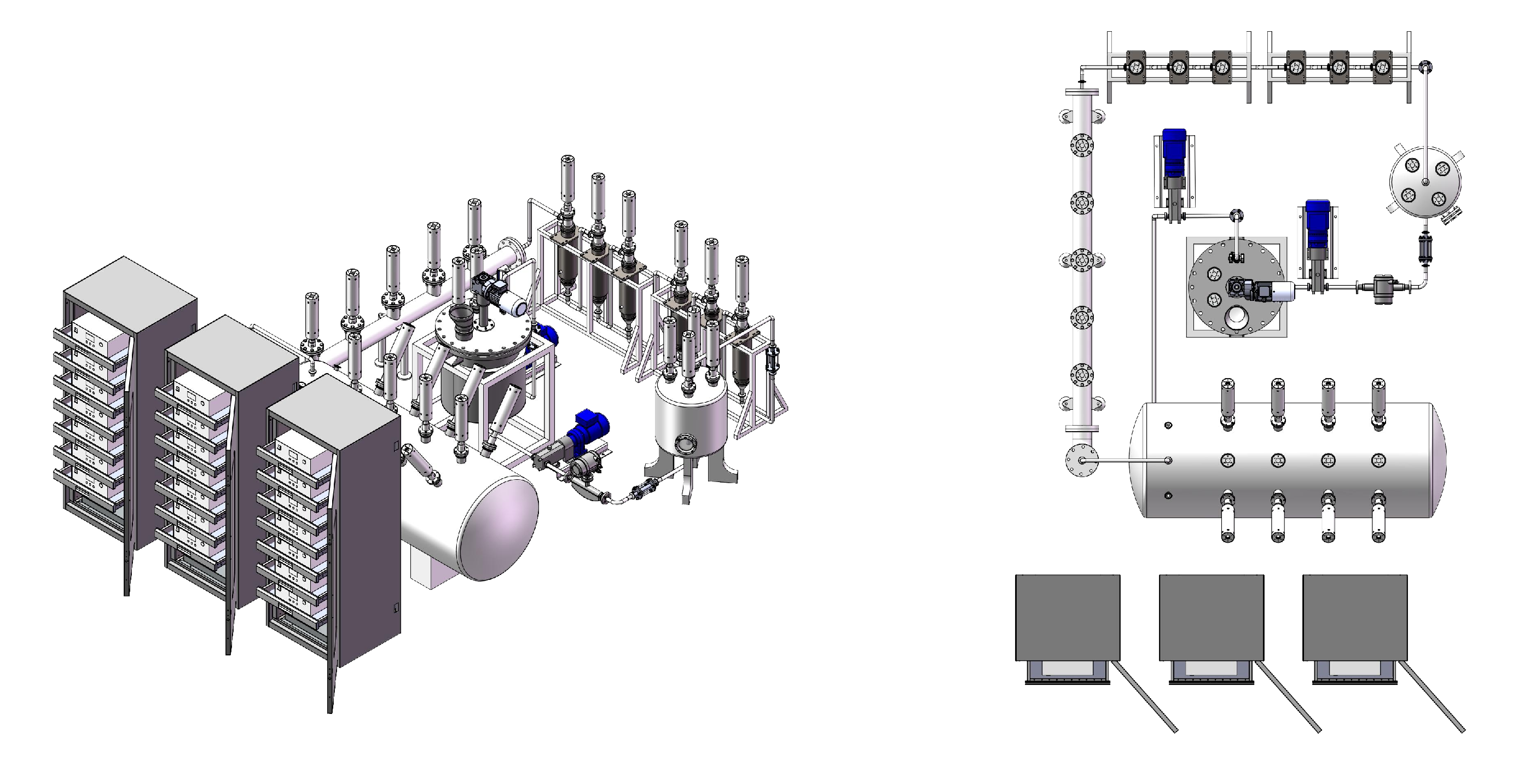

ultrasonic pilot plant test machine

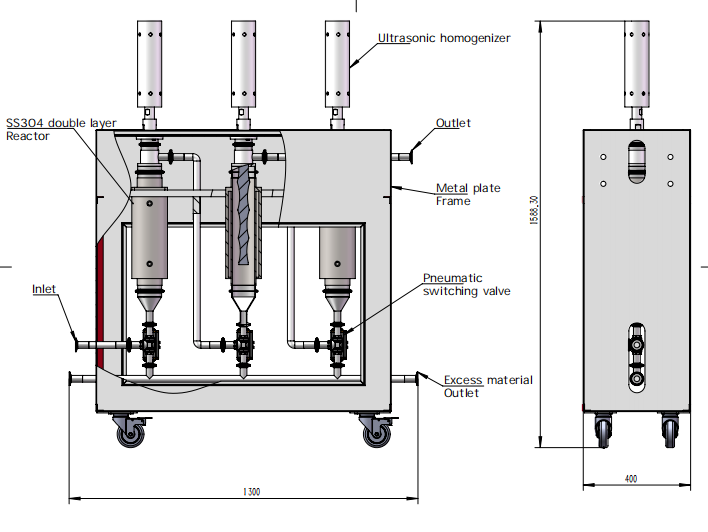

4 into 1 ultrasonic homogenizer system

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Famous Customers

![6RR6T{]1`HPT%8LQ2_KY4[2](http://iirorwxhjionlo5p.ldycdn.com/cloud/njBpqKrrRlkSoiopokjlj/6RR6T-1-HPT-8LQ2_KY4.png)

![C]LLCKM6_7%(R[{`{6_D]7U](http://iirorwxhjionlo5p.ldycdn.com/cloud/npBpqKrrRlkSoioppkjpj/C-LLCKM6_7-R-6_D-7U.png)