35Khz Ultrasonic Hand Welder Portable Ultrasonic Brass Inserts Equipment

Machine features:

1. Using high-quality ultrasonic transducer, 1200w high power, first choice for spot welding, it is special spot welding equipment for car door panels, car interiors, car spoilers, etc. Good stability and quality assurance.

2. It is suitable for welding, riveting, spot welding of large thermoplastic plastic products, as well as the inlay and edge pressing process of metal and plastic parts.

3. The design of the whole machine is exquisite, and the volume is small and does not occupy space.

4. The frequency is automatically adjusted, the output power is high, and the welding strength is high.

5. The main components are imported with high quality and have long service life.

6. Low noise and environmentally friendly working environment.

Work characteristics:

Fast: the welding time is short, 0.01-9.99 seconds can be set, improve work efficiency.

Strength: The tensile force is comparable to that of the product itself.

Quality: The welding part has a beautiful appearance, does not change color, and does not yellow.

Economy: No glue needed, material saving, environmental protection, and cost reduction.

Show details:

1. The metal paint cabinet is both beautiful and durable. The side hole is designed for ventilation and heat dissipation.

2. High-quality components. The main components are imported with high quality, with high power, strong output and stability.

3. Safety design. The rear of the chassis is grounded and equipped with a powerful silent cooling fan to ensure long-term work.

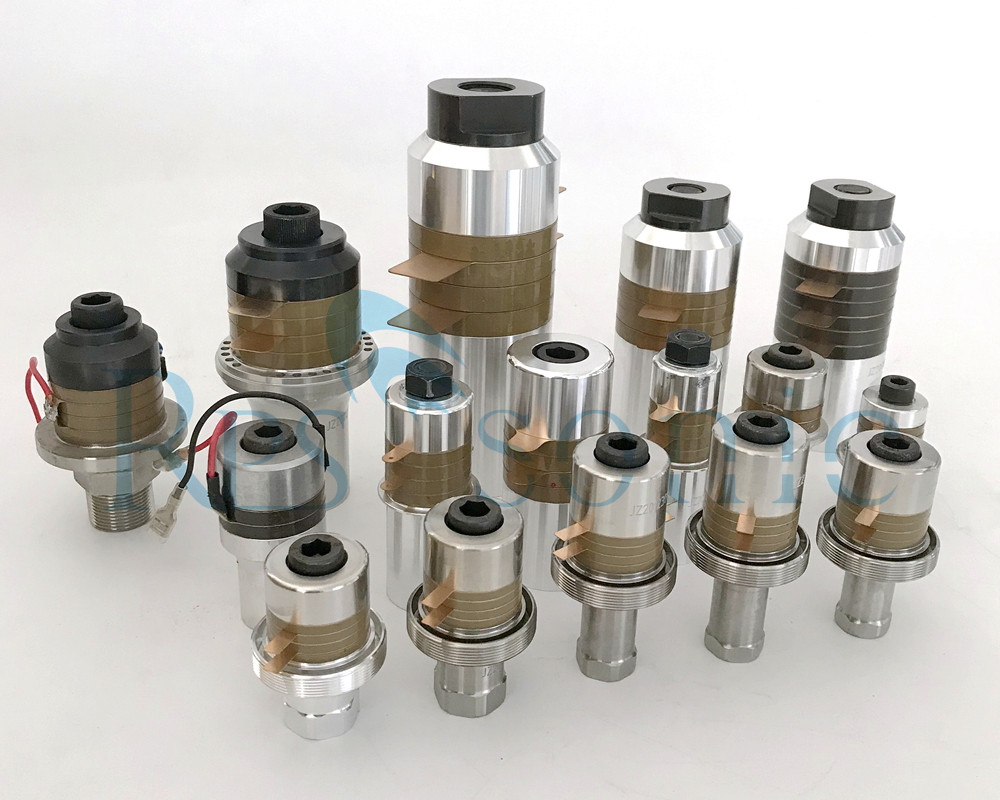

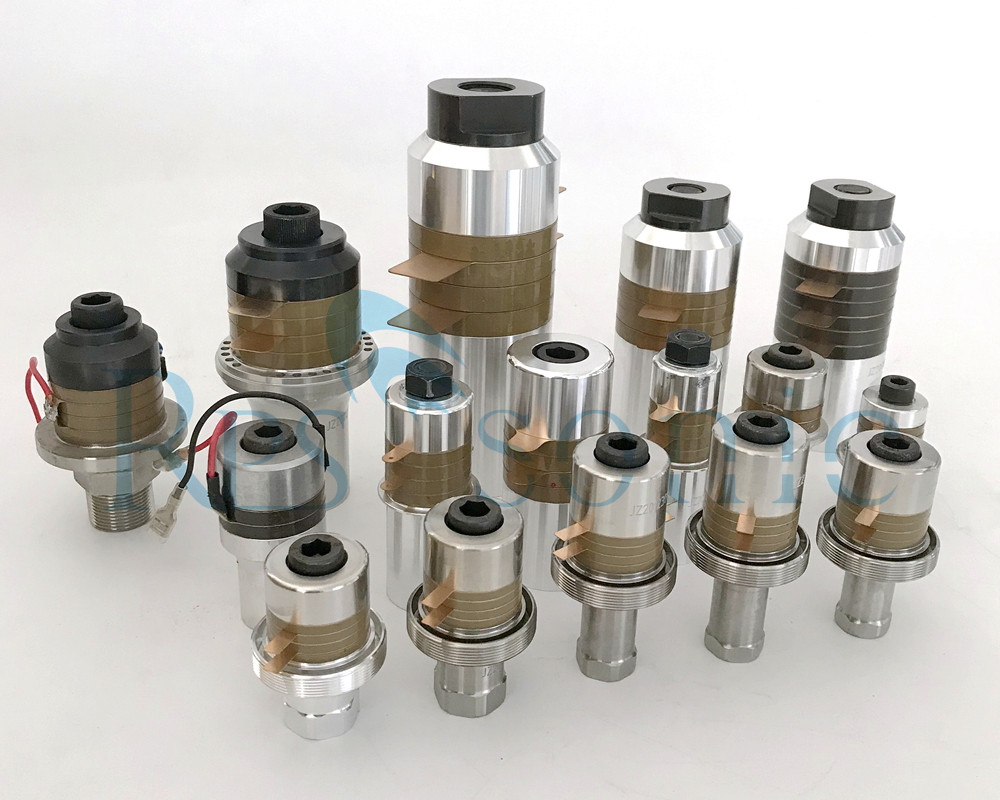

4. High-quality ultrasonic transducer with strong and stable output power.

5. Imported high-quality spare parts to ensure long-term stable work.

6. Titanium alloy molds are suitable for various environments and are not easily damaged.

7. Lengthen the frosted plastic handle to protect the transducer from damage.

8. The microcomputer display can accurately set the equipment and quickly adjust the parameters.

Application industry:

It is widely used in clothing industry, trademark industry, footwear industry, automobile industry, plastic electronics, household accessories industry, etc.

Apparel industry: front positioning of underwear and underwear stitches, welding of webbing and elastic bands, etc. You can also use rhinestones to replace the gun head.

Shoemaking industry: spot welding positioning of two pieces of leather.

Trademark industry: woven labels, printed labels, spot welding positioning, etc.

Plastic electronics: spot welding and riveting of small plastic parts, etc.

Houseware industry: fiber cotton spot welding, etc.

Automobile industry: spot welding of door sound insulation cotton, wiper seat, engine cover, water tank cover, etc.

Parameter

Item | Parameter | Advantage: | Application |

28Khz ultrasonic hand welder Straight type | ▪ 28Khz 800W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate. 2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it’d using life. 3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 8mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. |

28Khz ultrasonic hand welder Gun type |

35Khz ultrasonic hand welder Straight type | ▪ 35Khz 500W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 5mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. |

35Khz ultrasonic hand welder Gun type |

For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order . We also supply 20Khz 40Khz ultrasonic hand-weld welder. |

Kindly check the AMPLITUDE REFERENCE GUIDE for ULTRASONIC WELDING (in Microns (um)) table in the next page, you will find suit frequency for your application.

English

English