Description:

The core goal here isn't "defoaming" but "degassing" or "degassing"—that is, removing dissolved air from the dishwashing liquid before foam is generated.

Core Principle: How does ultrasound achieve degassing?

Ultrasonic degassing utilizes the physical properties of the "cavitation effect" and "gas solubility." The process can be divided into three steps:

Nucleation: When high-intensity, low-frequency ultrasound waves propagate through a liquid, they create periodic regions of density and sparseness. In these regions of sparseness, the liquid is stretched, and the local pressure decreases. This sudden drop in pressure significantly reduces the solubility of gas in the liquid, forcing the dissolved gas to precipitate, forming countless extremely tiny bubble nuclei ("gas nuclei").

Bubble Growth: During subsequent cycles of compression and rarefaction of the sound wave, these tiny gas nuclei continuously absorb the surrounding precipitated gas and, utilizing cavitation energy, continue to grow and expand. Ultrasonic energy provides the driving force for the aggregation and growth of bubbles.

Bubble Rising and Escape: As bubbles grow large enough, buoyancy overcomes the viscous force of the liquid, causing them to rise rapidly to the surface and burst, permanently separating the gas from the liquid.

Simply put: Ultrasonic waves act like a trigger, using energy to force dissolved air to escape, helping it to gather into large bubbles for rapid escape. This fundamentally solves the foaming problem before the liquid is put into use.

Why Degas Dishwashing Liquid?

In many industrial and high-precision applications, foam from dishwashing liquid or other cleaning agents is a major problem:

Precision ultrasonic cleaning: Used for cleaning optical lenses, semiconductor wafers, precision medical devices, and more. Dissolved gas in the liquid absorbs ultrasonic energy, severely weakening the cavitation effect and significantly reducing cleaning effectiveness. Pre-degassing is a critical pre-step to ensure effective cleaning.

Automated Filling and Spray Cleaning: On automated production lines, gas-rich dishwashing liquids are prone to foaming during the pumping and spraying process, leading to nozzle blockage, reduced pumping efficiency (cavitation), and uneven cleaning. Degassing ensures a stable process.

Product Quality and Appearance: For liquid dishwashing liquids, excessive bubbles can affect filling accuracy, packaging appearance, and consumer experience (making it appear "watered down").

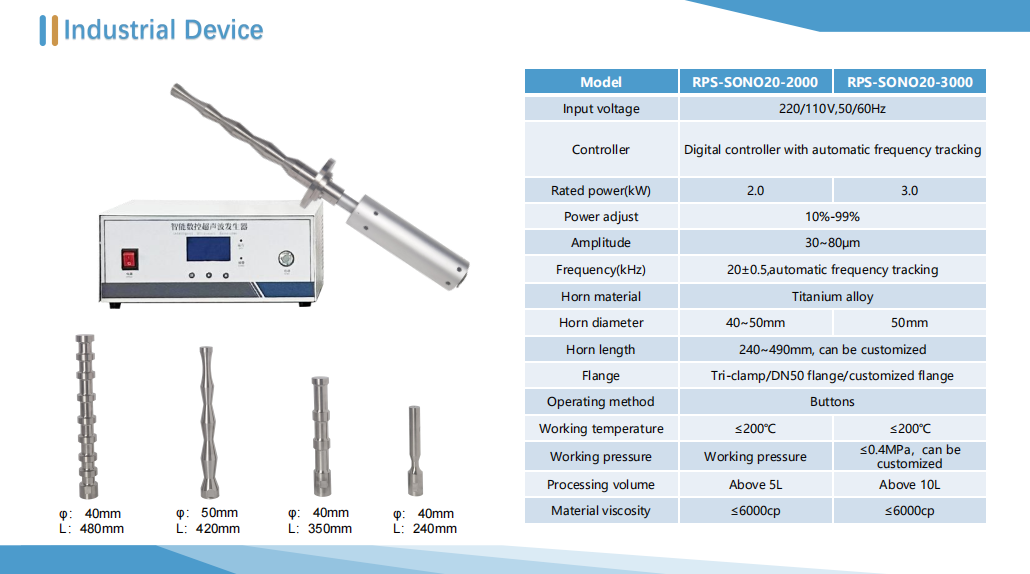

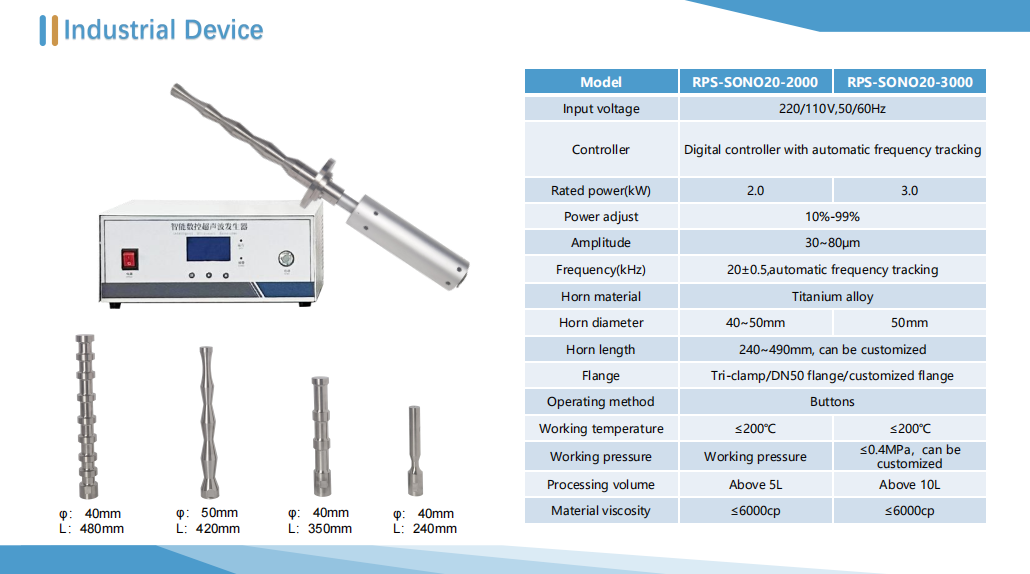

Specifications:

FAQ

1.What is the application of ultrasonic homogenizers?

Ultrasonic homogenizers can process a wide range of samples, including biological tissues, cells, microorganisms, plant material, pharmaceutical formulations, emulsions, suspensions, and various types of liquids.

2.Are there different sizes and power options available for ultrasonic homogenizers?

Yes, ultrasonic homogenizers come in various sizes and power options to accommodate different sample volumes and processing requirements. They range from small-scale applications to larger benchtop or industrial-scale systems.

3.How do I choose the suitable type for my application?

Consider factors such as sample volume, processing time, frequency and power settings, sample type, and the specific application requirements. Consulting with the manufacturer or supplier can help in selecting the most suitable device.

4.Can ultrasonic homogenizers combined with other techniques?

Yes, it can be used in combined with other techniques to enhance the efficiency and effectiveness of sample processing. For example, they can be used in conjunction with enzymatic treatments, mechanical agitation, or temperature control methods to achieve specific results.

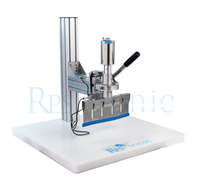

5.Can you supply the reaction tank with ultrasonic homogenizer?

Yes, of course. We can customized the reaction tank with your requirement. Any capacity is avilable