High Frequency Ultrasonic Welding Power Supply Plastic Welding

What’s ultrasonic generator?

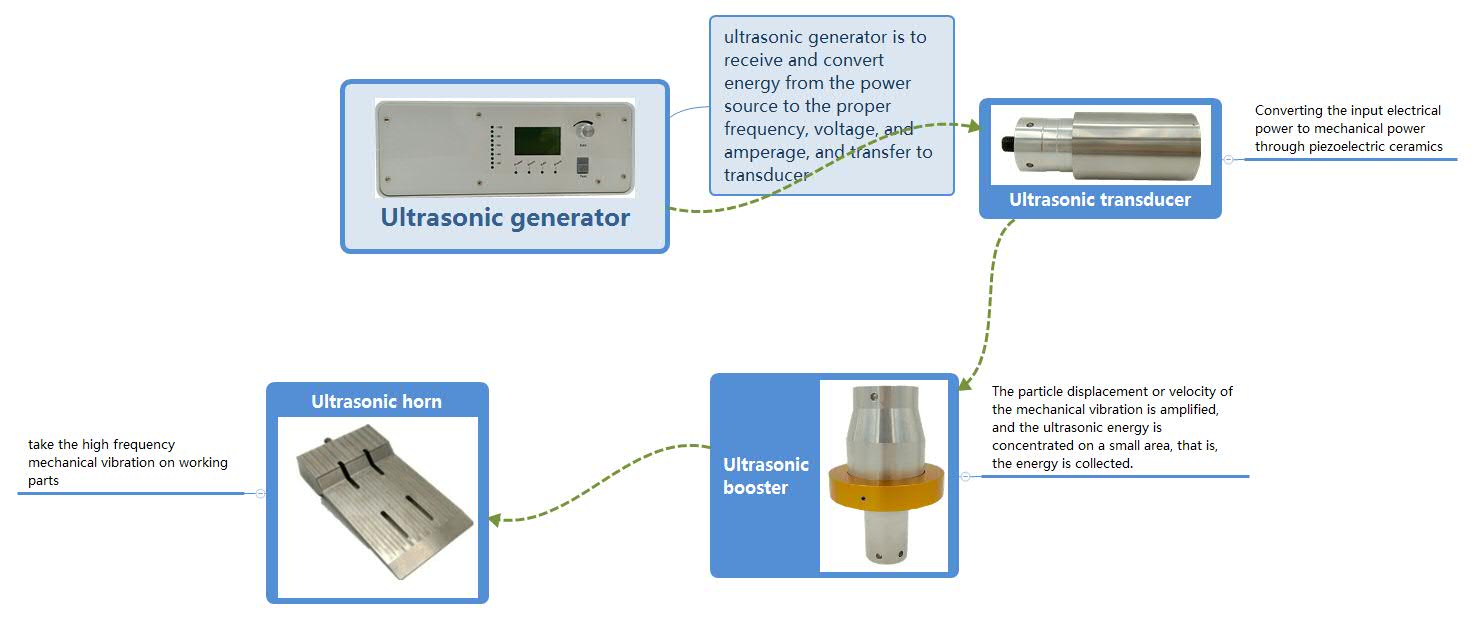

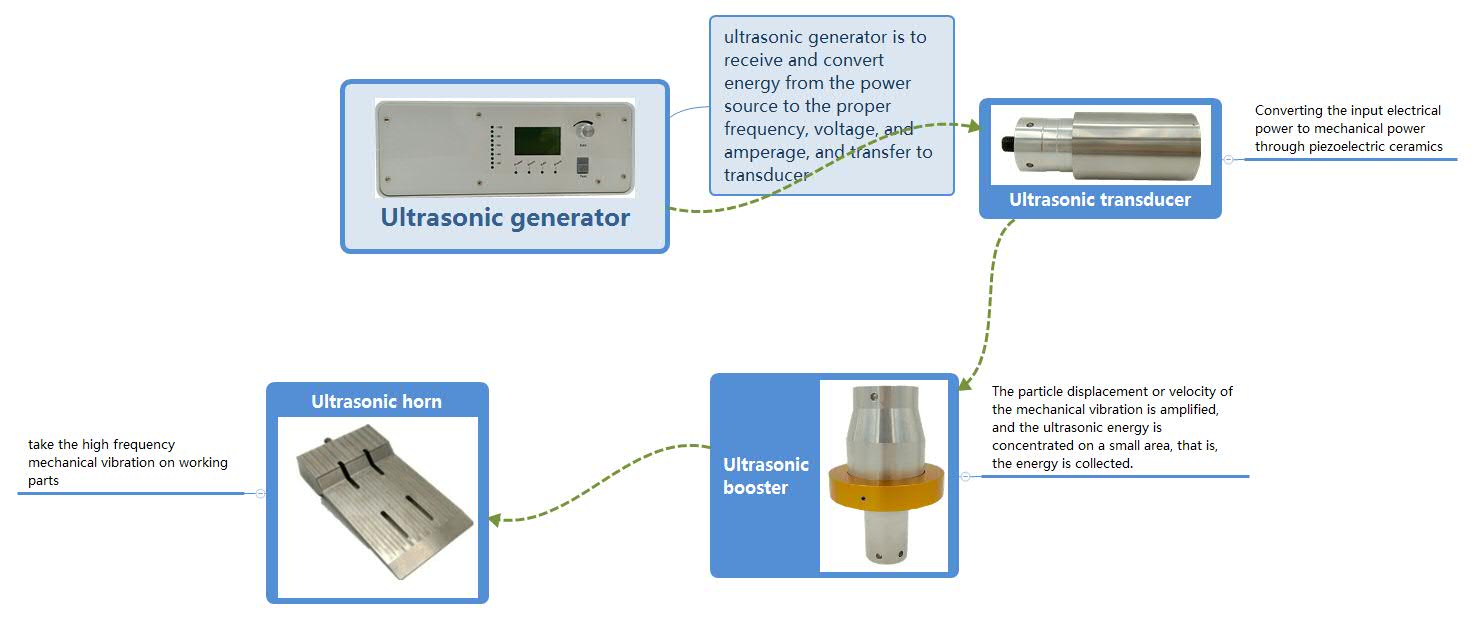

Ultrasonic generator, usually called ultrasonic power supply. Its function is to convert our mains (220V 110V or 380V, 50 or 60Hz) into a high frequency AC signal that matches the ultrasonic transducer. From the form of the amplifying circuit, a linear amplifying circuit and a switching power supply circuit can be used, and the high-power ultrasonic power source generally adopts a circuit form of a switching power supply in terms of conversion efficiency. Linear power supplies also have their own application range, which has the advantage that the circuit can be not strictly required.

Matching allows the operating frequency to change continuously and continuously. From the current situation in the ultrasound industry, ultrasonic generators are mainly divided into self-excited and separate excited power supply.

The principle of the ultrasonic generator is to first generate a signal of a specific frequency by a signal generator, which may be a sinusoidal signal or a pulse signal. This specific frequency is the frequency of the transducer, and is generally applied to ultrasonic in an ultrasonic device. The frequency is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz,70khz, 100KHz.

Our ultrasonic generator PCB can be used for non-woven bag making machine, paper cup sealing machine, three layers bag making machine, medical cloths making machine, plastic welding machine, plastic bag making machine,etc.

Application: Plastic, Toys, Electronic products, Non Woven products, Shore cover, Surgical products, lable, paper cups, mask, etc.

Our ultrasonic generator PCB advantages

1. DDS and PID high precision frequency control core.

2. Electric constant amplitude control system.

3. Welding amplitude setting range 0% – 100% by 1%.

4. Soft start, setting range 0-999MS, setprecison 1MS.

5. Three self-checking modes.

6. Pressure trigger/Time/Energy welding modes.

7. Six protections.

8. Less space, total weight 1.3KG.

Parameter:

High Frequency Ultrasonic Welding Power Supply Plastic Welding

Item | Parameter |

Power | 2000In max |

Frequency range | ±1000hz |

Operating temperature | ≤40℃ |

Frequency | 15~40Khz |

Amplitude adjust | 10%~100% |

Voltage | 110V/220V |

Circuit | Digital,separate excitation |

English

English