Application of ultrasonic sealing and cutting technology in circular looms

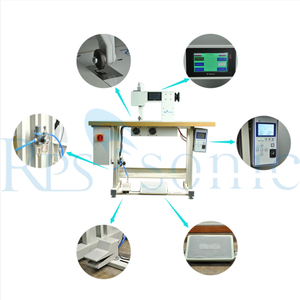

Core Definition: Ultrasonic sealing and cutting technology utilizes high-frequency mechanical vibration (ultrasound) applied through a welding head to fabric containing thermoplastic components. This causes the fabric to instantly generate heat through friction at the contact surface, melting and then re-solidifying under pressure, thus simultaneously completing the physical process of cutting and sealing the cut. When this technology is integrated into a circular loom, it achieves integrated continuous production of "weaving-length fixing-sealing and cutting."

Technology Integration Working Principle and Process: This is a precise mechatronics integrated collaborative process:

Signal Trigger: The PLC control system of the circular loom issues a cutting command when the preset value is reached, based on the fabric length or spindle rotation number fed back by the encoder.

Mechanical Clamping: Pneumatically or servo-driven upper and lower clamps move rapidly, firmly fixing the fabric on both sides of the predetermined cutting point, ensuring that the fabric is absolutely flat and free from stretching deformation during cutting.

Ultrasonic Action:

The generator produces a high-frequency electrical signal (typically 20kHz or 15kHz).

The transducer converts the electrical energy into longitudinal mechanical vibration of the same frequency.

The amplitude amplifier (amplifier) amplifies the vibration amplitude to a suitable level.

The welding head (tool head): As the final actuating component, its sharp edge contacts the fabric under pressure, concentrating the ultrasonic vibration energy to a very small cutting area.

Instantaneous sealing cut: Under the combined action of ultrasonic vibration, pressure, and the fabric's own tension, the fibers at the contact point (especially PP, PE, etc.) melt instantly and are cut, with the cut edge automatically sealed due to material fusion.

Reset cycle: The welding head lifts, the gripper releases, the cut fabric sheet is removed (stacked or conveyed), the system resets, and it awaits the next cycle. The entire process is completed within milliseconds, seamlessly integrated with the high-speed weaving rhythm.

Compared to traditional hot or mechanical knives, it solves the following industry pain points:

Pain points | Ultrasonic sealing and cutting solutions |

Fraying | Fundamental solution: The cut is fused together to form a strong polymer seal, preventing the weft yarn from falling off. |

The subsequent processes are complicated | By eliminating processes such as overlocking, binding, and singeing, semi-finished products that can be sewn or used can be obtained directly. |

Production speed bottleneck | The sealing and cutting action is extremely fast (<0.5 seconds), suitable for high-speed circular looms of 200-300 rpm, enabling continuous production. |

Environmental pollution | It is smokeless, odorless, and free of toxic gases, providing a clean working environment that meets environmental protection requirements. |

Energy consumption and thermal damage | The energy is highly concentrated, resulting in only localized instantaneous high temperatures at the point of application. The heat-affected zone is extremely small, and the fabric structure is not damaged, resulting in lower overall energy consumption. |

Cutting consistency | Digital control and constant parameters ensure that the length and cut quality are completely consistent across thousands of cuts. |

Application Scenarios:

This technology is particularly suitable for producing tubular braided products with extremely high requirements for cut integrity and strength:

High-end Flexible Intermediate Bulk Containers (FIBCs): Directly produces fixed-length tubular base fabric with strong cuts, allowing for direct sewing of the bag body, greatly improving the overall tear resistance and durability of the FIBC.

Fire Hose (Core Application):

This is the best example demonstrating its value. Fire hoses need to operate under high pressure; if the braided layer cuts come undone, the pressure-bearing capacity will drop drastically. Ultrasonic sealing provides a seamless fused cut, which is one of the key technologies to ensure its burst pressure.

High-Performance Industrial Hose Reinforcement Layers:

Such as hydraulic hoses, automotive fuel lines, air conditioning pipes, etc. Their internal braided reinforcement layers require smooth and strong cuts to prevent puncture of the inner rubber layer or the creation of stress concentration points.

Specialty Lifting Slings and Safety Webbing: The end treatment of webbing used for lifting and binding is crucial. Ultrasonic sealing provides high-strength, burr-free ends.

Geotechnical and Agricultural Pipes: Such as drainage pipes and seepage pipes, requiring clean cuts to prevent further tearing during use.

System Configuration and Selection Key Factors: Successful integration depends on the following factors:

Power and Frequency:

Power (1500W-4000W): Depends on fabric weight, width, and production speed. Thicker and faster production requires more power.

Frequency (15kHz or 20kHz): 20kHz is more common and quieter; 15kHz has a larger amplitude and is suitable for thicker materials.

Welding Head (Mold) Design: A core consumable, requiring customization. Materials are typically titanium alloy (lightweight and efficient) or mold steel (wear-resistant).

The cutting edge geometry (angle, curvature) directly determines cutting resistance, cut appearance, and lifespan.

Synchronization Control System: This is the "brain." The timing of the loom spindle, traction roller, gripper, and ultrasonic trigger must be precisely synchronized to ensure accurate cutting position (usually at points with the same weft density).

Clamping and Pressure System: Provides stable and uniform pressure. Insufficient pressure leads to weak fusion; excessive pressure accelerates welding head wear or damages the fabric.

Limitations and Challenges:

Material Limitations: Must contain a sufficient proportion of thermoplastic fibers (such as PP, PE, PET, PA). Ineffective or poorly effective on pure cotton, linen, fiberglass, aramid, etc.

High Initial Investment Cost: An imported or high-end ultrasonic system is expensive.

Professional Process Debugging: Requires adjusting the combination of parameters such as amplitude, pressure, trigger time, and cutting speed for different materials and specifications, relying on experience.

Welding Head Maintenance: Welding heads wear down after long-term use, requiring professional repair or replacement to maintain optimal cutting results.

Future Development Trends:

Intelligent and Adaptive Control: Integrates energy monitoring, frequency tracking, and other sensors to provide real-time feedback on sealing and cutting quality, automatically compensating for welding head wear or material changes, achieving "zero-defect" production.

Higher Power and Speed: Adapts to the needs of ultra-high-speed circular looms and ultra-thick, multi-layer composite materials.

Modular and standardized design: Makes ultrasonic sealing modules easier to install and upgrade onto circular looms of different brands and models.

Sustainability: Further reduces energy consumption and better handles recyclable bio-based polymer braided materials.

Conclusion: Ultrasonic sealing technology is to modern circular looms what an automatic transmission is to a car—it's not just a component, but a core system that liberates productivity, improves product quality, and defines high-end manufacturing. It successfully integrates a discrete "braiding-cutting-post-processing" workflow into a continuous, efficient, and clean automated process, making it an indispensable process choice for producing high-performance, high-reliability tubular braided products. For manufacturers aspiring to upgrade their production lines and enter the high-end market, investing in this technology has become an inevitable strategic choice.