What Is Radial Ultrasonic Wave Emission?

"Radial ultrasonic wave emission" refers to a special ultrasonic vibration mode in which vibrational energy expands and propagates outward along the radius or circumference of the tool.

To understand it, we need to compare it with the most common traditional ultrasonic vibration modes.

1. Traditional Mode: Longitudinal Vibration (Axial Vibration)

Imaginary Analogy: Like quickly and slightly "pressing" and "releasing" a spring.

Vibration Direction: The vibration direction is perpendicular to the working surface of the tool (welding head). The tool's front end undergoes a high-frequency "stretching-contraction" motion.

Application: This is the most common ultrasonic welding method, used for spot welding, riveting, cutting, etc. The welding head vibrates vertically up and down at high speed like a hammer.

2. Radial Wave Emission Mode: Radial Vibration

Imaginary Analogy: Imagine a rubber ring; you pinch its sides and quickly stretch it outwards and then release it. The diameter of the rubber ring will continuously increase and decrease. Or imagine a balloon; you continuously inflate and deflate it, and the balloon's surface expands and contracts radially.

Vibration Direction: Vibration occurs within the plane of the tool (usually a disc, cylinder, or roller), undergoing an "expansion-contraction" motion along its radius. Every point on the tool's working surface is making a radial back-and-forth motion parallel to the surface.

Core Characteristics: The energy wave of the vibration propagates radially outward from the center, or synchronously across the entire circumference.

Why is "radial wave generation" technology important?

This unique vibration mode gives it an irreplaceable advantage in continuous stitching/welding applications:

Suitable for continuous rolling welding: The welding head can be designed as a roller. As it rolls over the material, radial vibration acts continuously and evenly on the contact line, achieving seamless continuous welding. Longitudinal vibration welding heads struggle to achieve smooth rolling welding.

Uniform Energy Distribution: For weld lines of a certain width (e.g., patterns 1-5mm wide), radial vibration ensures that the material across the entire pattern width receives relatively uniform vibration energy, thus achieving uniform fusion.

Forming Special Welds: Using patterned welding wheels, aesthetically pleasing and functional sealing lines (such as simulated stitches, dot matrix, and grid patterns) can be press-welded onto materials, which is crucial for creating sealed joints.

Reducing Surface Damage: Compared to excessive surface friction that can be caused by some vertical vibrations, a well-designed radial vibration system can better control the heat-affected zone.

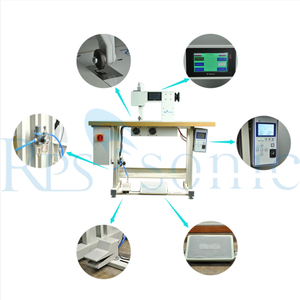

Typical Application Equipment: Ultrasonic Radial Wave Sewing/Sealing Machine

In this equipment, the core component is a welding wheel (roller) with a precise pattern.

The transducer system inside or connected to this welding wheel excites the wheel to generate radial vibration.

When the material to be welded (such as non-woven fabric) passes between the welding wheel and the die, the high-frequency radial vibration friction causes the material to melt instantaneously and locally, and then re-solidifies under the pressure of the welding wheel's pattern, forming a completely sealed "weld" corresponding to the pattern.

Core Applications: Industrial textiles and protective equipment (this is the most important and mature market)

Medical protective clothing (especially high-level protective clothing)

Application Description: Used for sewing seams in protective clothing.

Why it's revolutionary:

Traditional needle and thread stitching leaves tens of thousands of tiny pinholes, potential channels for viruses, bacteria, blood, or chemical liquids to penetrate. Ultrasonic radial wave stitching fuses the fabric together, forming a completely seamless, non-porous seal—the key to truly "liquid-proof" protective clothing.

Results: High seam strength, smooth and comfortable, absolutely airtight. Widely used in the production of medical protective clothing during SARS, Ebola, and COVID-19 outbreaks.

Chemical protective clothing and industrial dustproof clothing: Using the same principle, it prevents hazardous chemicals, toxic dust, or particulate matter from entering through the seams, protecting workers in industrial, chemical, and fire-fighting fields.

Outdoor and high-performance clothing and equipment: For waterproof jackets, ski suits, and raincoats: Achieves perfect adhesion and sealing of waterproof seam tape, or directly welds multiple layers of fabric to ensure no leaks at the seams.

Tents, sleeping bags, and tarps: Used to create completely waterproof seams, preventing water seepage in rainy or humid environments.

Inflatable Products: Sealing and air chamber partition welding for products such as paddleboards, inflatable boats, and water toys. Radial wave welding creates continuous, uniform, and high-strength airway seals.

Home Textiles and Bedding: High-end down comforters, down jackets, and pillows: Used for creating "stand-up" or "box-like" structures and sewing down lining layers. It welds the fabric without piercing the lining, perfectly preventing down leakage, and resulting in thin, soft seams.

Car Seat Covers, Interior Trim, and Sun Visors: Provides both decorative stitching and functional fastening, eliminating the need for thread trimming, resulting in a beautiful and durable product.

Packaging Industry: Tea bags, coffee bags, and traditional Chinese medicine bags: Radial wave technology completes sealing and cutting in one step. The seal is tight, effectively preserving the flavor of the contents, and production is extremely fast.

Filters: Used for welding the edges of filter media or forming specific filter structures, providing excellent sealing and preventing fiber contamination.

Medical Sterile Packaging Bags (Tyvek bags, etc.) These bags offer tight seals, are easy to tear, and ensure the sterility of the internal medical devices.

III. Other Specialized Industrial Applications

Automotive Airbags: Used for welding seams in airbags, requiring extremely high consistency and strength, and free of burrs or sharp threads to prevent injury during airbag deployment. Ultrasonic welding perfectly meets these requirements.

Electronics Industry: Used for welding certain non-metallic casings, battery insulation films, etc., where continuous sealing is required.

Composite Material Joining: Used for joining certain thermoplastic composite sheet or roll materials to form continuous, aesthetically pleasing seams.

Summary

Ultrasonic radial wave emission is essentially an innovation in the direction of ultrasonic energy transmission. It transforms the traditional "hammering" vibration into a "concentric circle expansion and contraction" vibration. This transformation allows ultrasonic technology to be perfectly applied to continuous, sealed, and high-speed "sewing" scenarios, thus giving rise to ultrasonic suturing technology, which is crucial in fields such as medical protection and outdoor equipment.

The application of ultrasonic radial wave generation technology is the "ultimate solution" for high-requirement, high-performance sealing joint scenarios. Originating in the field of medical protection, which is related to life safety, it is constantly expanding to more manufacturing fields that pursue reliability, sealing performance, and high quality.

English

English