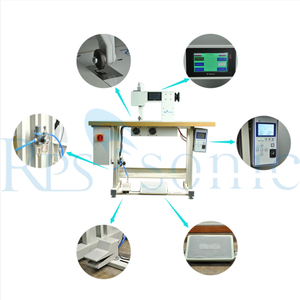

What's The Ultrasonic Radial Wave Sewing Machine?

When welding thin materials such as TPU, silk, and pleated filter elements, the core reason for choosing an ultrasonic radial wave sewing machine is its technological advantages: low damage, uniform energy transfer, and adaptability to the characteristics of thin materials. This perfectly solves the core pain points of thin material welding (easily broken, uneven welds, thermal deformation, and sealing/connection failure). The following analysis covers three aspects: technical principles, pain points in thin material welding, and the targeted advantages of radial wave generation, combined with specific material characteristics to illustrate its suitability:

I. Clarifying the Core Concept: The Technical Essence of Ultrasonic Radial Wave Sewing Machines

The core of ultrasonic welding is to use high-frequency vibration (20-40kHz) to generate heat through friction between the molecules at the material interface, achieving fusion and bonding without the need for additional glue or thread. "Radial wave generation" refers to the uniform radiation of ultrasonic energy from the circumference of the welding head to the center (or from the center to the circumference), rather than traditional linear wave generation (energy propagation in a single direction). The difference from traditional methods: the vibration direction of common ultrasonic welding heads (molds) is longitudinal vibration perpendicular to the contact surface. Radial wave emission refers to the vibration direction of the welding head (usually a disc or a specially textured roller) within its plane, expanding and contracting radially. This energy transfer method, combined with the continuous feeding structure of a sewing machine, enables continuous operation of "feeding, vibrating, and welding simultaneously," making it particularly suitable for the continuous processing needs of thin materials.

II. Targeted Advantages of Ultrasonic Radial Wave Emission (Why it's Suitable for Thin Materials)

1. Uniform Energy Transfer, Avoiding Localized Overmelting/Damage

Radial wave emission characteristics: Energy radiates uniformly from the welding head contact surface, acting on the "planar area" of the thin material rather than "linear/point-like" areas. The energy density per unit area is low and evenly distributed, avoiding the "energy concentration points" of traditional linear wave emission that cause perforation and scorching of thin materials. Example: When welding 0.2mm TPU, radial wave welding heads can control the molten layer thickness to 5-10μm, achieving adhesion without damaging the substrate; while linear wave welding is prone to excessively thick molten layers (>20μm) due to energy concentration, leading to tensile fracture.

Suitable for pleated filter cartridges: The height difference in the pleated structure can cause uneven contact in traditional processes. Radial wave welding's planar energy transfer can cover the uneven surfaces of the pleats, ensuring that each contact point receives uniform energy and avoiding over-melting at the top of the pleats and poor welding at the bottom.

2. Low-temperature rapid welding, reducing thermal deformation: The "frictional heat generation" in ultrasonic welding only occurs at the material interface (molecular-level vibration), resulting in a low overall temperature (typically 30-50℃ lower than thermal welding) and extremely short welding time (single weld < 0.1 seconds). The heat diffusion range of thin materials is < 0.5mm, with almost no thermal deformation. Example: Silk fibers have a low melting point (polyester silk approximately 255℃). The low-temperature characteristics of radial wave welding prevent fiber melting and breakage, maintaining the soft feel of silk; while hot welding easily leads to localized charring and hardening of silk.

Compatible with TPU: TPU is a thermoplastic elastomer, prone to aging and hardening at high temperatures. Rapid radial wave welding reduces the thermo-oxidative aging of TPU, maintaining its elasticity and waterproof performance.

3. Non-destructive connection, maintaining material integrity. No needle or thread piercing or glue penetration is required. The welding process only involves molecular melting and bonding, completely preserving the original structure and properties of the thin material:

Silk: Prevents fiber breakage, maintaining the fabric's breathability and softness;

Pleated filter element: Does not clog micropores (filtration accuracy ≥99.9%), does not damage the pleated structure (no loss of filtration area);

TPU: No pinholes, ensuring waterproof and leak-proof performance (weld seam waterproof rating up to IPX7).

High weld strength: The molecular-level bonding of the weld seam approaches the strength of the substrate itself, with tensile strength reaching 80-90% of the strength of the thin material itself, far exceeding needle and thread stitching (approximately 50-60%) and glue bonding (approximately 40-50%).

4. Adaptable to continuous operation, improving production efficiency: The ultrasonic radial wave sewing machine integrates a "feed-weld-cut" structure, achieving welding speeds of 10-30 m/min, far exceeding glue bonding (<1 m/min) and hand stitching (<5 m/min), making it suitable for mass production of thin materials (such as filter production lines, continuous welding of TPU waterproof fabric, and seams in silk garments).

Smooth and aesthetically pleasing weld seams: The radial wave surface pressing results in uniform weld width (typically 1-3 mm), with no needle and thread marks or glue residue, making it particularly suitable for thin material products with high appearance requirements (such as high-end silk garments and medical TPU film products).

5. Adaptable to various thin material properties, highly versatile

For thermoplastic materials (TPU, polyester film, nylon thin film): Direct molecular melting bonding, no additives required;

For natural/synthetic fiber fabrics (silk, polyester thin fabric): Can be used with specialized welding heads (such as patterned radial wave welding heads) to achieve "point bonding + surface bonding," ensuring strength without affecting breathability;

For composite substrates of pleated filter cartridges (such as polyester film + non-woven fabric): Can weld two different thin materials simultaneously without compromising their respective functions (filtration of the film, support of the non-woven fabric).

III. Main Application Areas

This technology is widely used in industrial textiles requiring sealing, reinforcement, and aesthetics:

Protective Clothing: Medical protective clothing, chemical protective clothing. This is one of the most important applications, ensuring complete seals at seams to prevent the penetration of viruses, bacteria, or chemical liquids.

Outdoor Products: Sealing seams in tents, sleeping bags, waterproof jackets, and inflatable products (such as paddleboards).

Home textiles: Down lining stitching for high-end down comforters, pillows, and mattress covers.

Packaging industry: Sealing of tea bags, filters, and medical packaging bags.

Automotive interiors: Stitching and decoration of seat covers, headrests, sun visors, etc.

IV. Summary: The "Adaptation Logic" of Radial Wave Sewing Machines for Thin Material Welding The core requirements for thin materials are **"low damage, high strength, high efficiency, and preservation of properties"**, and ultrasonic radial wave technology perfectly matches the welding needs of thin materials such as TPU, silk, and pleated filter elements by: → Uniform energy transfer to solve "local overmelting/incomplete welding"; → Low-temperature rapid solution to "heat deformation/aging"; → No puncture/no penetration to solve "structural damage"; → Continuous operation to solve "mass production".

This makes it the optimal solution to replace traditional processes. In addition, the device can be further adapted to the thickness and characteristics of different thin materials by adjusting the ultrasonic frequency (28kHz for thinner materials, 40kHz for precision welding), welding head pressure (0.1-0.5MPa), and vibration amplitude (10-30μm), making it extremely flexible.

English

English