Comprehensive Analysis of Ultrasonic Metal Wire Harness Welding

Ultrasonic metal wire harness welding is a highly efficient solid - state joining technology widely used in the automotive, electronics, and home appliance industries. It is used to permanently weld multiple metal wires (wire harnesses) or metal sheets together with conductors.

What is Ultrasonic Metal Wire Harness Welding?

It is a welding method that utilizes high - frequency ultrasonic vibration energy (typically 20kHz, 35kHz, or 40kHz) under pressure to achieve atomic bonding between two or more layers of metal materials in a solid state.

1.Core Principle:

①Solid - state welding: The metal does not melt throughout the entire process. This is the fundamental difference between it and fusion welding methods such as soldering and arc welding.

②Energy Form: It utilizes mechanical vibration energy, not thermal energy.

③Mechanism of Action: Ultrasonic vibration generates shear force and friction at the welding interface, breaking down the oxide layer and contaminants on the metal surface, allowing pure metal atoms to come into close contact, forming a strong metallurgical bond under pressure and interatomic forces.

Working Principle and Process

The welding process is typically completed within one - tenth to a few seconds and can be divided into three stages:

1.Initial Pressurization Stage:

①The wire harness to be welded is fixed between a dedicated welding mold (upper mold/welding head and lower mold/anvil).

②The welding machine applies a constant static pressure (clamping force) to compress the wire harness.

2.Ultrasonic Vibration Stage:

①An ultrasonic generator converts 50/60Hz power frequency electricity into a high - frequency electrical signal.

②A transducer (piezoelectric ceramic or magnetostrictive) converts the high - frequency electrical signal into mechanical vibration of the same frequency.

③An amplitude modulator amplifies the amplitude of the mechanical vibration to the required level (typically 5 - 50µm).

④The welding head transmits the amplified high - frequency vibration to the interface of the metal wire harness to be welded.

⑤Under the combined action of pressure and vibration, the interface undergoes:

a)Oxide Layer Removal: Vibration and friction scrape away the oxide film and organic matter on the metal surface.

b)Plastic Flow: The metal undergoes microscopic plastic deformation at the interface.

c)Atc)mic diffusion: Pure metal surfaces diffuse into each other under the influence of interatomic forces, forming a bond.

3.Pressure holding and curing stage:

Ultrasonic vibration stops, but pressure continues for a period of time.

This stage allows the weld interface to cool and solidify under pressure, ensuring a stable weld joint structure and forming a dense, strong weld.

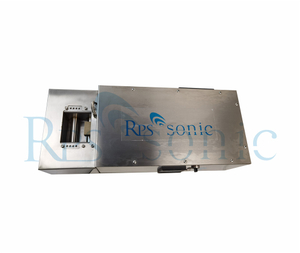

Main System Components

A typical ultrasonic metal welding machine includes:

1.Ultrasonic generator: The "brain" of the system, providing and controlling high - frequency electrical energy.

2.Acoustic components (energy conversion system):

a)Transducer: Electrical energy → mechanical vibration energy.

b)Amplifier: Amplifies the vibration amplitude.

c)Welding head: Directly transmits ultrasonic energy to the workpiece. Its shape is specifically designed according to the product.

3.Pneumatic pressurization system: Provides and controls the pressure required for welding.

4.Frame and housing: Supports the entire system and provides safety protection.

5.Dedicated welding molds (upper and lower molds): Used to fix and position the wire harness, ensuring efficient energy transfer.

Key Process Parameters

Welding quality is determined by the following key parameters:

1.Welding Power/Energy: The total energy output during the welding process. Modern welding machines often use an "energy mode" for control to ensure consistency.

2.Welding Pressure: The clamping force applied to the wire harness.

3.Welding Time: The duration of ultrasonic vibration.

4.Amplitude: The vibration amplitude of the welding head end face. Different materials and wire diameters require different amplitudes.

5.Trigger Position/Depth: The point at which the ultrasonic waves are triggered when the welding head descends to a preset position.

Key Advantages

Compared to traditional welding (such as tin soldering), ultrasonic metal welding has significant advantages:

1.No solder or flux required:

a)Saving ca)sts and avoiding heavy metal contamination from solder (such as tin).

b)Nb) risk b)f corrosion at the solder joint, and better conductivity (pure metal connection).

2.Low - temperature connection: The overall workpiece temperature is far below the melting point, preventing annealing and not affecting the properties of the base material.

a)Very safe for welding around heat - sensitive components.

3.Energy - saving and environmentally friendly:

a)Energy is applied only to a tiny welding area, resulting in extremely low energy consumption.

b)Nb) smb)ke or exhaust emissions, making it environmentally friendly.

4.High welding speed: Typically, a weld joint is completed within 0.1 - 0.5 seconds, resulting in extremely high efficiency and suitability for automated mass production.

5.High weld strength and low resistance: Forms a metallurgical bond, with mechanical strength and conductivity superior to molten solder connections.

6.High consistency: Precise parameter control ensures stable and reliable weld quality.

7.Weldable dissimilar metals: Capable of welding dissimilar material combinations that are difficult to join using fusion welding, such as copper - aluminum and copper - nickel.

Application Areas

1.Automotive Industry (Largest Application Area):

①Power Battery Modules: Busbar connections between cells, connections between tabs and wiring harnesses.

②Wire Harnesses: Crimping and welding of internal wires in fuse boxes, relays, connectors, etc.

2.Electronics and Appliances:

①Lithium Batteries: Welding of tabs and wires for cylindrical batteries such as 18650.

②Motors: Welding of lead wires from winding coils.

③Relays and transformers: Internal coil connections.

④Solar Photovoltaics: Busbar connections for solar panels.

⑤Home Appliances and Consumer Electronics: Connections of various internal wire harnesses.

Limitations

1.Limited workpiece thickness:Currently mainly used for welding thin sheets, fine wires, and foils. Single wire diameter is typically no more than 25mm², and the total thickness of multiple layers is limited.

2.High mold cost: Welding heads and base molds require precision design and manufacturing for specific products, resulting in high costs and a lack of versatility.

3.High requirements for workpiece preparation: The area to be welded needs to be kept clean; severe oil contamination or oxidation can affect weld quality.

4.Sometimes weld marks may be left: Slight indentations may appear on the surface contacted by the welding head.

In summary, ultrasonic metal wire harness welding is a fast, clean, reliable, and efficient "green" connection technology. With the rapid development of new energy vehicles, energy storage, and the electronics industry, it is becoming increasingly important, becoming an indispensable part of modern precision manufacturing.