What is Ultrasonic Adhesive Spraying?

Traditional adhesive spraying typically uses pneumatic nozzles, breaking the adhesive solution into droplets with high-pressure gas. Ultrasonic adhesive spraying, however, utilizes ultrasonic energy to "tear" the adhesive solution or melt into uniform droplets of micron or even nanometer size through a high-frequency vibrating atomizing head (usually made of titanium alloy or stainless steel). These droplets are then precisely delivered to the substrate surface through a low-pressure (usually laminar airflow) system.

Core Working Principle:

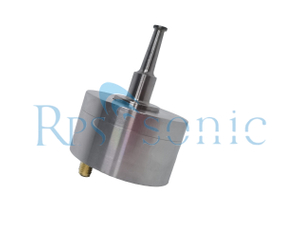

Ultrasonic Atomization: The core component is a piezoelectric ceramic transducer, which converts high-frequency electrical signals (typically 20kHz - 180kHz) into mechanical vibrations of the same frequency.

Capillary Wave Formation: The vibration is transmitted to the tip of the atomizing head, causing the thin layer of adhesive flowing over its surface to generate "capillary waves."

Droplet Separation: When the vibration energy exceeds the surface tension of the liquid, the liquid at the wave crest is ejected, forming highly uniform tiny droplets (with excellent monodispersity).

Gentle Delivery: The generated droplets are enveloped and guided to the workpiece by a ring of gentle laminar air (“sheath gas”), avoiding the splashing and “spraying” problems caused by high pressure in traditional spray guns.

Key Technical Advantages: Compared with traditional pressure spraying and two-phase flow spraying, ultrasonic spraying has significant advantages: Extremely high uniformity and consistency: The droplet size distribution is extremely narrow, forming a very uniform, thin, and continuous coating without “orange peel” effect.

Extremely low flow control capability: Precise spraying from microliters per minute (µl/min) to milliliters per minute (ml/min) can be achieved, greatly saving material (savings can reach over 50%), especially suitable for expensive functional materials.

Nearly no overspray and bounce: The low droplet velocity and low kinetic energy allow for precise adhesion to the target area, reducing contamination and waste.

Suitable for complex and sensitive formulations: The gentle atomization process does not rely on high pressure, therefore it does not shear polymer chains, making it ideal for sensitive materials such as polymer solutions, nanoparticle suspensions, and biological agents.

Handles high-viscosity liquids: By reducing viscosity through heating, it can handle adhesives with higher viscosities than traditional spraying methods.

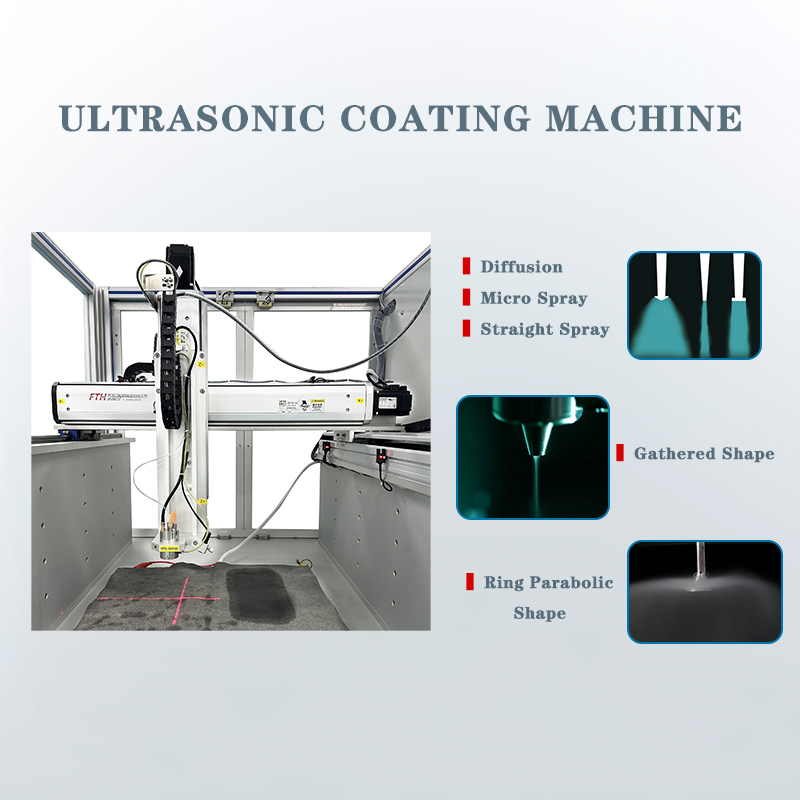

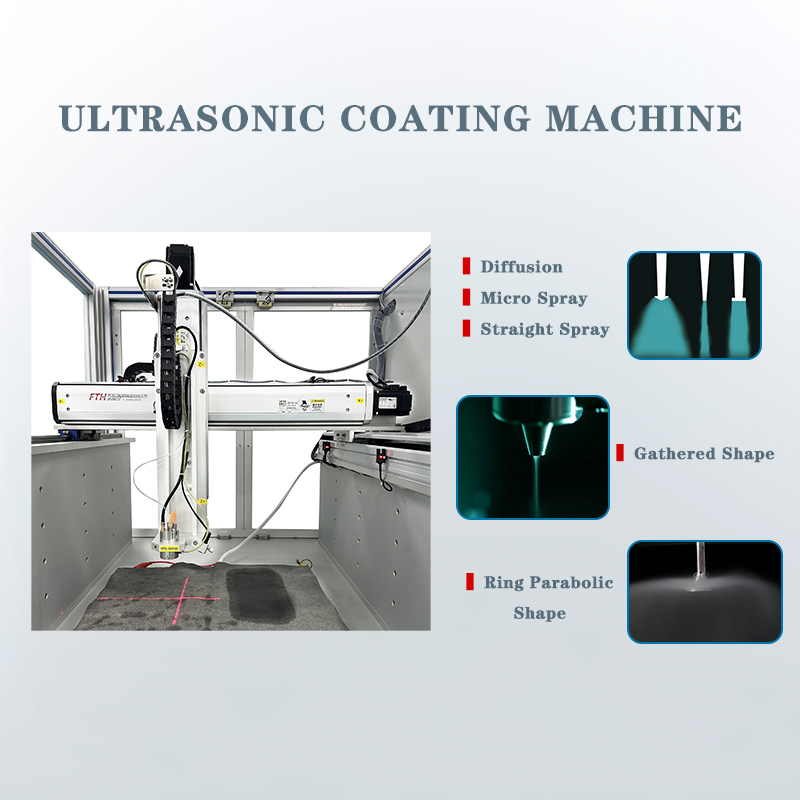

Flexible pattern control: Through nozzle shape design and motion control, various spraying patterns such as slits, rectangles, and circles can be achieved with clear boundaries.

Typical application areas: Due to its precision and efficiency, this technology is widely used in high-end manufacturing:

Medical devices

Cassium hydrophilic coating

Wearable sensor electrode coating

Drug-eluting stent coating

Functional coating for medical textiles

Electronics and semiconductors

Flexible printed electronics: Spraying conductive silver paste and carbon nanotube ink to form circuits.

Photovoltaic cells: Fabrication of perovskite layers and electron transport layers.

Chip packaging: Spraying underfill adhesive and thermally conductive adhesive.

Lithium battery manufacturing: Electrode coating (slurry), replacing or supplementing traditional slit coating.

Textiles and composite materials

Hot melt adhesive spot spraying for clothing (non-woven fabrics, breathable membrane composites).

Resin or adhesive spraying for composite preforms (prepregs).

Automotive Industry

Intelligent, low-VOC bonding of automotive interior components.

Local adhesive applications in lightweight structures.

System Composition

A typical ultrasonic adhesive spraying system includes:

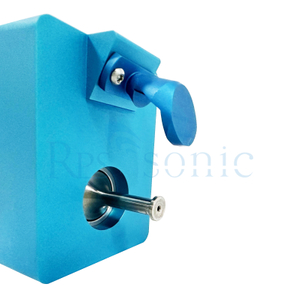

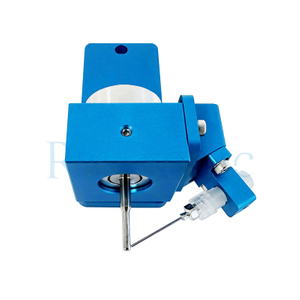

Ultrasonic nozzle: The core atomizing component.

High-frequency generator: Drives nozzle vibration.

Precision fluid delivery system: Includes injection pumps, screw pumps, etc., for precise liquid supply control.

Air path control system: Provides clean, stable laminar sheath gas.

Motion control platform: XYZ three-axis or robotic arm for automated spraying along complex paths.

Heating system (optional): Used for handling high-viscosity hot melt adhesives or adhesives requiring heat preservation.

Technical Challenges and Considerations

Initial investment cost: Equipment cost is higher than traditional spraying systems.

Liquid compatibility: Liquid properties (viscosity, surface tension, solids content) must be matched with the atomization frequency, potentially requiring initial process adjustments.

Nozzle maintenance: Although the risk of clogging is lower than with pneumatic nozzles, regular cleaning is still necessary to prevent dry adhesive buildup.

Production Capacity Limitations: For large-area coatings requiring extremely high deposition rates, it may not be as efficient as traditional high-speed spraying.

Summary: Ultrasonic adhesive spraying is a disruptive precision coating technology. With its superior uniformity, extremely high material utilization, and friendliness to sensitive materials, it is becoming an indispensable process in high-end manufacturing and R&D fields.

It is particularly suitable for:

Applications involving expensive materials (e.g., biopharmaceuticals, nanomaterials).

Applications requiring extremely high coating quality (e.g., optical films, functional coatings).

Applications requiring complex patterns or micro-area coatings (e.g., flexible electronics).

Handling adhesive formulations sensitive to shear forces.