The Application of Ultrasonic Technology in Solar Cells

Ultrasonic technology plays an increasingly important role in the fabrication, processing, and performance enhancement of solar cells. It primarily utilizes the localized extreme temperatures, pressures, shock waves, and microjets generated by ultrasonic cavitation (the rapid formation and violent collapse of tiny bubbles in a liquid) to improve material properties and processing.

The following are the main applications of ultrasonic technology in the field of solar cells:

1. Material Preparation and Processing

* Nanomaterial Dispersion: In the fabrication of perovskite solar cells, quantum dot solar cells, or slurries using nanoparticles, ultrasound is a key tool for dispersing nanoparticles (such as carbon nanotubes, graphene, and metal nanoparticles). It effectively breaks up agglomerates, forming a uniform and stable slurry, thereby improving the conductivity and uniformity of the electrodes.

* Perovskite Precursor Solution Treatment: Ultrasonic treatment of perovskite precursor solutions can promote the complete dissolution of materials such as lead iodide, reduce crystal nuclei in the solution, and thus obtain more uniform perovskite films with higher crystallinity during subsequent film formation.

2. Thin Film Deposition and Film Formation Process

* Ultrasonic Spray Pyrolysis: This is a thin film deposition technique. Ultrasonic waves atomize the precursor solution into extremely small and uniform droplets, which are then sprayed onto a heated substrate to instantly form a thin film. This method can be used to deposit transparent conductive oxide films (such as zinc oxide and tin oxide) or perovskite films, offering advantages such as high material utilization, good film uniformity, and suitability for large-area fabrication.

Assisted Crystallization: Applying ultrasound during the crystallization process of perovskite films can regulate crystallization kinetics. The cavitation effect and vibration energy of ultrasound promote crystal nucleation and inhibit dendrite growth, resulting in larger grains, fewer defects, and denser perovskite polycrystalline films, significantly improving device efficiency and stability.

3. Battery Film Spraying

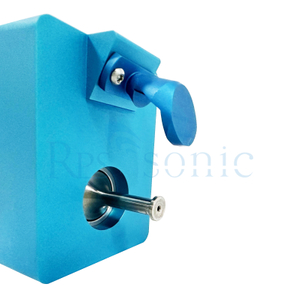

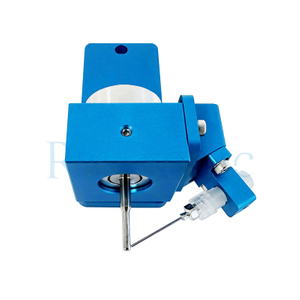

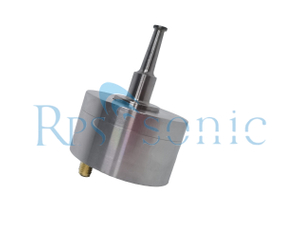

Working Principle: The core lies in the ultrasonic atomizing nozzle. It contains a piezoelectric transducer that generates high-frequency mechanical vibration when a high-frequency electrical signal (typically >20 kHz) is applied.

Atomization: When the precursor solution (such as perovskite precursor solution, transparent conductive oxide sol, etc.) flows through the vibrating nozzle tip, it is torn into extremely small (micrometer-scale) and highly uniform droplets, forming a "mist". Deposition: This "mist," carried by a carrier gas (such as nitrogen), is directed to the heated substrate surface.

Film Formation: Upon impact with the hot substrate, the droplets evaporate instantly, and the solute deposits, gradually forming a uniform and dense thin film.

Ultrasonic spraying is particularly suitable for novel solar cell technologies with high requirements for film uniformity, material utilization, and low-temperature processing

3.1. Perovskite Solar Cells

This is the most disruptive application area of ultrasonic spraying.

Uniform Large-Area Film Formation: The quality (uniformity, crystallinity) of the perovskite film directly determines the cell efficiency. Ultrasonic spraying can directly form a high-quality precursor wet film on the substrate in one step, greatly simplifying the process of traditional spin coating (unsuitable for large-area production).

High-Throughput and Roll-to-Roll Production: The nozzles can be linearly arranged for continuous spraying on moving flexible substrates (such as stainless steel foil, PET/PEN), perfectly compatible with roll-to-roll large-scale production, and is one of the key technological paths for the commercial mass production of perovskite.

High material utilization: Traditional spin coating wastes over 95% of the material, while ultrasonic spraying, being a directional deposition process, achieves a material utilization rate of over 90%, significantly reducing the cost of expensive chemicals (such as FAI and PbI₂).

Multilayer structure fabrication: It can be used not only to spray perovskite light-absorbing layers but also electron transport layers (such as SnO₂) and hole transport layers, enabling a complete spraying process.

3.2. Transparent conductive electrodes: Used for spraying transparent conductive oxide thin films, such as AZO (aluminum-doped zinc oxide) and ITO. Compared to expensive vacuum sputtering, ultrasonic spraying is a low-cost, atmospheric pressure alternative.

3.3. Other thin-film batteries: CIGS/CZTS thin-film solar cells: Can be used for spraying precursor solutions or nanoparticle inks.

Dye-sensitized solar cells: Used for spraying TiO₂ porous framework layers or counter electrode catalyst layers.

4. Welding and interconnection: Ultrasonic welding:

Used in module encapsulation for connecting metal busbars between solar cells. This is a low-temperature, solid-state welding technology that uses high-frequency vibration friction to generate heat for connection, avoiding potential thermal damage to the solar cells from high temperatures. It is particularly suitable for temperature-sensitive thin silicon wafers or novel solar cells.

Advantages Summary:

**Non-thermal effect-dominated:** Many processes can be performed at room temperature or low temperatures, reducing thermal stress.

**High efficiency and uniformity:** Cavitation effects enable intense mixing, dispersion, and accelerated reactions at the microscale.

**Green and environmentally friendly:** Typically reduces the use of hazardous chemicals or shortens processing time.

**Wide applicability:** Potential applications range from silicon-based to emerging perovskite and organic photovoltaics.

As solar cell technology develops towards higher efficiency, lower cost, and greater flexibility, ultrasonic technology, as a highly efficient and green process enhancement tool, will see its applications deepen. Especially in the large-scale printing fabrication of perovskite solar cells, the low-temperature process of silicon heterojunction cells, and the manufacturing of flexible devices, ultrasonic technology is expected to become one of the key technologies for improving performance and reducing manufacturing costs.

item | Traditional methods | ultrasonic spraying technology |

Coating uniformity | Average, prone to orange peel and dripping | Excellent, nanometer-level precision control. |

Material utilization rate | Low (30%-60%) | High (>90%) |

Impact on workpiece | May cause damage due to high pressure or liquid impact. | Non-contact, gentle, and non-damaging. |

Complex shape coverage | Poor, many blind spots | Excellent, good shape retention |

Process controllability | Low | Extremely high, digital programming control |

Coating thickness | Thicker, harder to control | Ultra-thin, with precision down to the submicron level |

V. Applications and Future Prospects

Current Applications: Primarily used in the manufacture of high-end endoscopes such as disposable duodenoscopes, bronchoscopes, and colonoscopes, as well as the remanufacturing and repair of reusable endoscopes.

Future Trends:

Multifunctional Composite Coatings: Multiple layers of coatings with different functions are sequentially sprayed onto the same surface (e.g., antireflective coating followed by hydrophobic coating).

Intelligentization and AI Integration: Utilizing machine vision to automatically identify the spraying area and optimizing the spraying path and parameters through AI algorithms.

New Material Development: Such as "self-healing" coatings that automatically repair minor scratches; or drug-loaded coatings that release therapeutic drugs during examination.

In conclusion, ultrasonic spraying technology for semiconductor endoscopes is one of the key manufacturing processes ensuring the high performance, high reliability, and safety of modern precision medical endoscopes, and is a jewel in the crown of high-end medical device manufacturing.

English

English