The Advantages And Features of Ultrasonic Atomization Machines

Ultrasonic atomizing machines (with the ultrasonic atomizing nozzle/system as their core component) offer a series of significant advantages and unique characteristics compared to traditional atomization technologies (such as pressure spraying and two-fluid pneumatic spraying) in precision coating and thin film deposition. These advantages make them an ideal choice for high-precision fields such as solar cells, semiconductors, and medical coatings.

The following is a detailed analysis of their core advantages and characteristics:

I. Core Advantages

* **Superior Thin Film Uniformity and Consistency**

* **Principle:** Ultrasonic vibration generates highly monodisperse droplets (extremely narrow size distribution range).

The resulting film on the substrate has uniform thickness, no "orange peel" effect, and allows for nanometer-level thickness control. This is crucial for the functional layers of solar cells, which require precise optical and electrical properties.

* **Extremely High Material Utilization**

* **Principle:** Concentrated atomization direction, low atomization speed ("soft mist"), and precisely controllable spray pattern (fan-shaped or cone-shaped).

Material utilization can reach over 90%, far exceeding the 30%-50% of traditional spraying. This significantly reduces waste and production costs associated with expensive materials such as perovskite precursors and precious metal nano-inks.

**Zero Damage to Substrate and Coating**

Principle: The atomization process does not rely on high-pressure gas; droplet velocity is low, resulting in minimal impact.

It is particularly suitable for spraying onto fragile, finely structured substrates, such as pre-prepared nanowire arrays, microelectronic circuits, and flexible polymer films (PET, etc.), without damaging the underlying structure.

**Excellent Process Controllability and Repeatability**

Principle: The atomization volume is directly and linearly controlled by the ultrasonic frequency/power and liquid delivery rate, with highly stable parameters unaffected by pressure fluctuations.

A wide process window and excellent batch-to-batch repeatability facilitate stable quality in large-scale production.

**Wide Applicability, Capable of Handling Complex Fluids**

Principle: Physical vibration atomization allows for adaptability to a certain range of liquid viscosities (typically up to several hundred cP).

It effectively atomizes suspensions or slurries containing nanoparticles, fibers, or shear-sensitive substances, minimizing agglomeration or material degradation, making it suitable for preparing composite functional coatings.

Low Operating Costs and Environmentally Friendly

Principle: No compressed air or high-pressure gas source is required (except for a small amount of sheath gas used for molding), resulting in low energy consumption.

Low operating noise and low energy consumption, coupled with minimal overspray and bounce, reduce solvent evaporation and air pollutant emissions, leading to a cleaner working environment.

II. Key Features

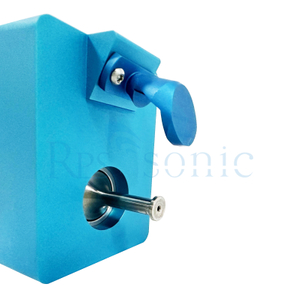

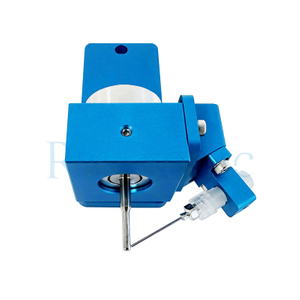

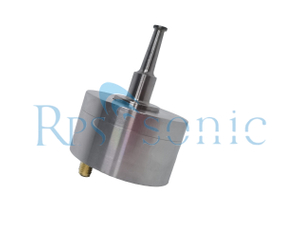

Unique Atomization Mechanism: Relies on the high-frequency mechanical vibration of the piezoelectric transducer (typically from 20kHz to several hundred kHz) to generate micron-sized droplets at the tip of the liquid capillary wave, a gentle physical process.

Spray Characteristics:

Low-velocity "soft mist": The average droplet velocity is typically 0.1-2 m/s.

Low initial momentum: Deposition relies primarily on the guidance of the carrier gas and substrate attraction, rather than inertial impact.

Adjustable droplet size: Adjustable by changing the ultrasonic frequency. Higher frequencies produce smaller droplet sizes (e.g., a 120kHz nozzle produces much smaller droplets than a 20kHz nozzle).

Precise system configuration: The core components are an ultrasonic generator, a piezoelectric transducer, and a spray head. Integration with high-precision liquid delivery systems (such as screw pumps and syringe pumps) and motion platforms is required.

Sensitive to liquid properties:

Advantages: Insensitive to flow rate changes, maintaining stable droplet size over a wide flow range.

Challenges: The viscosity, surface tension, density, and solids content of the liquid itself affect the optimal atomization frequency and effect, often requiring parameter optimization for specific solutions.

Applications:

Fuel cells: Spraying catalyst layers (Pt/C slurry).

Medical devices: Spraying drug coatings and antibacterial coatings onto stents or implants.

Semiconductors: Spraying photoresists, PI imine, and electronic packaging materials.

Glass coating: Spraying anti-reflective layers and self-cleaning coatings.

In summary, the core value of ultrasonic atomizing machines lies in their ability to transform functional liquids into high-quality thin films in a highly controllable, gentle, and efficient manner. It is not only a tool for improving product performance but also a key technology for achieving precision manufacturing, cost reduction, efficiency improvement, and green production. Although the initial investment may be high, its comprehensive advantages are very prominent in the processing of high-value materials and the production of high-quality products.

item | Traditional methods | ultrasonic spraying technology |

Coating uniformity | Average, prone to orange peel and dripping | Excellent, nanometer-level precision control. |

Material utilization rate | Low (30%-60%) | High (>90%) |

Impact on workpiece | May cause damage due to high pressure or liquid impact. | Non-contact, gentle, and non-damaging. |

Complex shape coverage | Poor, many blind spots | Excellent, good shape retention |

Process controllability | Low | Extremely high, digital programming control |

Coating thickness | Thicker, harder to control | Ultra-thin, with precision down to the submicron level |

V. Applications and Future Prospects

Current Applications: Primarily used in the manufacture of high-end endoscopes such as disposable duodenoscopes, bronchoscopes, and colonoscopes, as well as the remanufacturing and repair of reusable endoscopes.

Future Trends:

Multifunctional Composite Coatings: Multiple layers of coatings with different functions are sequentially sprayed onto the same surface (e.g., antireflective coating followed by hydrophobic coating).

Intelligentization and AI Integration: Utilizing machine vision to automatically identify the spraying area and optimizing the spraying path and parameters through AI algorithms.

New Material Development: Such as "self-healing" coatings that automatically repair minor scratches; or drug-loaded coatings that release therapeutic drugs during examination.

In conclusion, ultrasonic spraying technology for semiconductor endoscopes is one of the key manufacturing processes ensuring the high performance, high reliability, and safety of modern precision medical endoscopes, and is a jewel in the crown of high-end medical device manufacturing.

English

English