The Application of Ultrasonic Technology in The Spraying of Drug-eluting Stents

Drug-eluting stents (DES) involve coating a traditional metallic stent with a layer containing an anti-proliferative drug (such as paclitaxel or sirolimus) and a polymer. After implantation into a narrowed blood vessel, the drug is slowly released into the surrounding tissue, inhibiting excessive proliferation of vascular endothelial cells, preventing in-stent restenosis, and maintaining long-term vascular patency. It is an important minimally invasive method for treating coronary artery disease.

Core Principles and Functions

Drug Loading: The polymer (biocompatible material) matrix covering the stent surface is loaded with drugs that inhibit cell proliferation and have anti-inflammatory effects.

Sustained Release Mechanism: Under the influence of blood flow and the vascular microenvironment, the drug is released at a predetermined rate, continuously acting on the stent area.

Inhibition of Excessive Proliferation: The released drug effectively prevents excessive growth of scar tissue (intima) after stent implantation, which is the main cause of stent restenosis.

Maintaining Patency: By controlling cell proliferation, the lumen of the blood vessel is kept permanently open, restoring myocardial blood supply.

Key Technical Aspects

Stent Material: Typically a metallic alloy (such as stainless steel or cobalt-chromium alloy) providing mechanical support. Drug Selection: Commonly used anticancer drugs (such as paclitaxel) and immunosuppressants (such as sirolimus).

Polymer Coating: Determines the rate and time of drug release, requiring excellent biocompatibility and mechanical properties.

Manufacturing Process: Precise spraying technology ensures uniform coating and controllable drug content.

Advantages: Reduced Restenosis Rate: Compared to bare-metal stents, DES significantly reduces the risk of in-stent restenosis and reoperation.

Minimally Invasive Treatment: Implanted via percutaneous coronary intervention (PCI), eliminating the need for open-chest surgery.

Ultrasonic technology is a key and advanced technology in the spraying process of drug-eluting stents, primarily used for precise, uniform, and controllable drug coating.

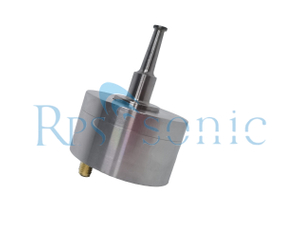

1. Core Principle: Ultrasonic Atomization Spraying

Traditional spraying techniques (such as pneumatic spraying) may result in inconsistent droplet sizes, uneven coatings, or low drug utilization. Ultrasonic spraying utilizes high-frequency ultrasonic vibrations (typically above 20 kHz) to break the surface tension of liquids, atomizing drug-containing solutions or suspensions into uniform micro- or even nano-sized droplets.

2. Key Advantages in DES Spraying

* Extremely High Uniformity and Consistency: It produces highly uniform droplets, enabling the formation of extremely thin, uniform coatings on complex stent surfaces (including grooves and connecting rods). This is crucial for ensuring precise and consistent drug loading on each stent.

* Controllable Coating Thickness and Structure: Precise control of coating thickness, from single-layer to multi-layer and from micro- to nano-scale, is possible through precise adjustment of parameters (such as frequency, flow rate, and scan speed). This is particularly useful for developing advanced structures such as multi-drug layered coatings or gradient release coatings.

* High Drug Utilization and Cost Savings: Strong atomization directionality and high target deposition rate reduce drug splashing and waste during spraying, which is significant for expensive therapeutic drugs such as rapamycin and paclitaxel derivatives.

Suitable for sensitive drugs: The process is gentle, generally not generating high heat or strong shear forces, which is beneficial for maintaining the stability of bioactive drugs such as proteins and nucleic acids.

Clog-free design: Unlike pressure nozzles, ultrasonic nozzles have larger or no orifice diameters, making them less prone to clogging and suitable for continuous spraying of viscous solutions containing polymers (such as PLGA).

3. Typical application process flow

Solution preparation: The active drug and biodegradable polymers (such as PLGA, PVP-HA) are dissolved together in a solvent to form a uniform spray solution.

Scaffold pretreatment: Metal or biodegradable material scaffolds are cleaned and subjected to plasma treatment to improve coating adhesion.

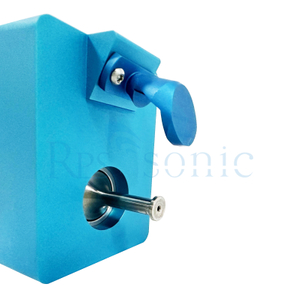

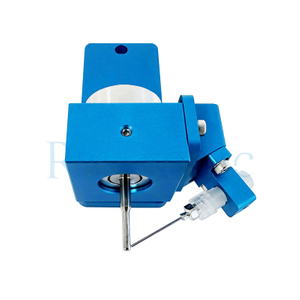

Ultrasonic spraying: The scaffold is fixed on a precision rotating/moving device.

The ultrasonic nozzle atomizes the drug solution and, through a programmable motion system, evenly deposits droplets onto the scaffold surface.

The solvent evaporates rapidly, forming a solid drug-polymer coating.

Drying and curing: Residual solvent is thoroughly removed in a controlled environment.

Quality Control: Coating uniformity, drug loading, and drug activity are assessed using methods such as gravimetric analysis, scanning electron microscopy (SEM), and high-performance liquid chromatography (HPLC).

4. Advanced Applications and Innovation Directions

Multilayer Coating Systems: A primer layer is applied first to increase adhesion, followed by a drug-containing layer, and finally a controlled-release layer to control the drug release rate.

Composite Drug/Functionalized Coatings: Different drugs are sequentially applied to achieve sequential release; or combined with nanoparticles to achieve targeted or responsive release.

Biodegradable Scaffold Coatings: Uniform coating of absorbable scaffolds such as PLLA presents greater challenges; ultrasonic technology offers advantages due to its gentleness.

5. Challenges and Considerations

Complex Parameter Optimization: Extensive process development and quality design are required for ultrasonic frequency, power, liquid flow rate, scaffold movement speed, and temperature.

Coating Stability: It is essential to ensure that the coating does not peel or crack during scaffold curling and expansion (fatigue testing).

Solvent Selection: Solvents with suitable volatility and biocompatibility must be used, ensuring extremely low residue levels in the final product.

Aseptic and Scalable: Scale-up processes from laboratory to GMP production require rigorous process validation and control.

Summary: Ultrasonic spraying technology has become one of the standard processes in the production of modern high-end drug-eluting stents (DES). It directly improves the safety and efficacy of DES by providing a precise, uniform, and repeatable coating solution—uniform coatings reduce the risk of thrombosis or restenosis caused by uneven local drug distribution, while precise load control ensures stable therapeutic effects. As DES evolves towards "personalized" and "multifunctional" designs, ultrasonic technology will continue to play a central role in the manufacturing of next-generation stents.

item | Traditional methods | ultrasonic spraying technology |

Coating uniformity | Average, prone to orange peel and dripping | Excellent, nanometer-level precision control. |

Material utilization rate | Low (30%-60%) | High (>90%) |

Impact on workpiece | May cause damage due to high pressure or liquid impact. | Non-contact, gentle, and non-damaging. |

Complex shape coverage | Poor, many blind spots | Excellent, good shape retention |

Process controllability | Low | Extremely high, digital programming control |

Coating thickness | Thicker, harder to control | Ultra-thin, with precision down to the submicron level |

V. Applications and Future Prospects

Current Applications: Primarily used in the manufacture of high-end endoscopes such as disposable duodenoscopes, bronchoscopes, and colonoscopes, as well as the remanufacturing and repair of reusable endoscopes.

Future Trends:

Multifunctional Composite Coatings: Multiple layers of coatings with different functions are sequentially sprayed onto the same surface (e.g., antireflective coating followed by hydrophobic coating).

Intelligentization and AI Integration: Utilizing machine vision to automatically identify the spraying area and optimizing the spraying path and parameters through AI algorithms.

New Material Development: Such as "self-healing" coatings that automatically repair minor scratches; or drug-loaded coatings that release therapeutic drugs during examination.

In conclusion, ultrasonic spraying technology for semiconductor endoscopes is one of the key manufacturing processes ensuring the high performance, high reliability, and safety of modern precision medical endoscopes, and is a jewel in the crown of high-end medical device manufacturing.

English

English