20Khz Ultrasonic homogenizer equipment for Graphene Preparation

The degassing process of ultrasonic probe sonicator

In general conditions, there is a certain number of dissolved gas in the liquid and form a state of equilibrium level, the concentration of gas may be affected by many factors including atmospheric pressure, agitating strength and temperature. Ultrasonic degassing can break the equilibrium state and reduce the gas concentration in the solution.

ultrasonic Sonochemistry homogenizer,Ultrasonic technology as a means of physical and tools to chemical reactions in the media produced a series of close to the extreme conditions. This energy not only to promote or stimulate a number of chemical reactions, speed up the chemical reaction speed, even some of the chemical reaction can change the direction of some unexpected results and a miracle. This is the Sonochemistry. Sonochemistry can be applied to almost all chemical reactions, such as separation and extraction, synthesis and degradation, bio-diesel production, Governance of micro-organisms, the degradation of toxic organic pollutants, deal with biodegradable, biological cells crushed, and Dispersed and cohesion, and so on.

Parameter

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Advantages:

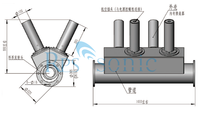

1. Our ultrasonic reactor equipped with customized stainless steel 316 (teflon)lid, sandblasted surface of lid, five ports on the kettle lids (liquid feeding mouth, solid feeding mouth, ultrasonic mouth, mechanical stirring mouth, temperature measurement mouth)

2. Customized stirring paddle (full stainless steel material, double layer push type paddle)

3. Ultrasonic vibration system(can provide 110V/220V power supply )

4. Used for continuous flow production

5. The ultrasonic power, ultrasonic time, amplitude and frequency can be adjusted to meet the requirements of different working conditions.

6. The mixing speed is stable and adjustable.

7. 99 hour process control timer, control the total working time: from 1 second to 99 hours, pause the current running task in real time.

8. The working time is displayed in cumulative state.

9. On / off pulse timer: ensure that the high-intensity processing of temperature sensitive samples, on and off cycle can be set from 1 second to 99 minutes.

10. Automatic amplitude compensation to ensure that the probe amplitude does not change due to load changes during the ultrasonic process.

11. Sample overload / over temperature protection device.

12. Automatic frequency tracking, automatic fault alarm.