20Khz Ultrasonic Welding Machine with Touch Screen for Automobile Welding

Description

Ultrasonic plastic welding machine with modes of time model and energy model; it can automatically track and display real-time frequency, with amplitude stepping function, welding amplitude range up to 10-100 (1% accuracy). There is also amplitude compensation; welding quality management (time, energy mutual detection), including clear traceable welding records (operation statistics) to control your welding quality in real time. It also features transducer overload protection, mold impedance analysis and protection to protect your equipment. Powerful, high quality and high welding stability. It is your best choice for plastic welding.

B.Function

◆ Real-time frequency automatic tracking display;

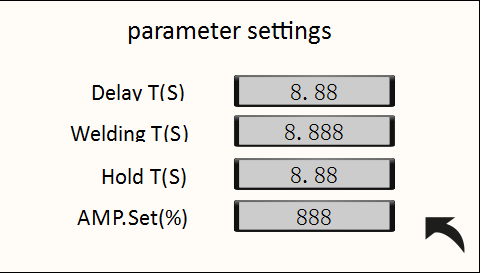

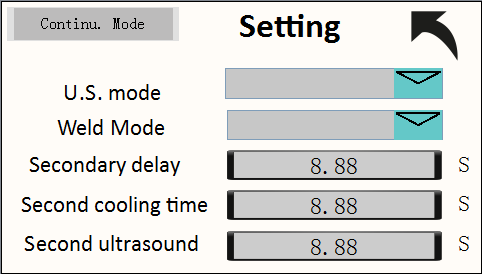

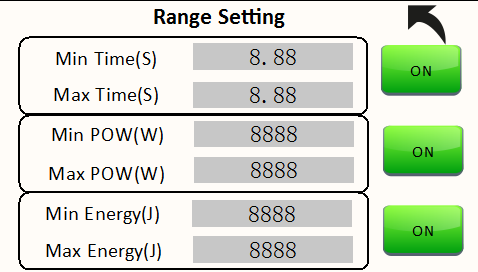

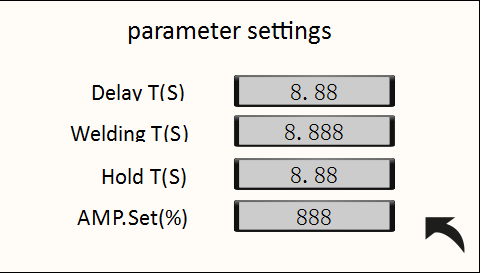

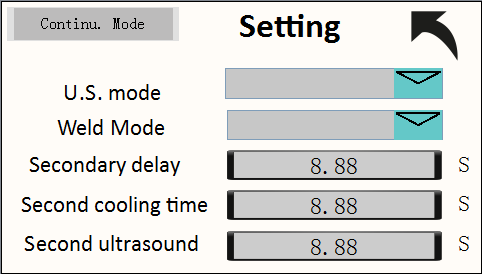

◆ Welding mode: time, energy

◆Amplitude stepping function;

◆Welding amplitude 10-100 adjustable (1% accuracy)

◆Amplitude compensation

◆Mold impedance analysis + protection

◆Overload protection;

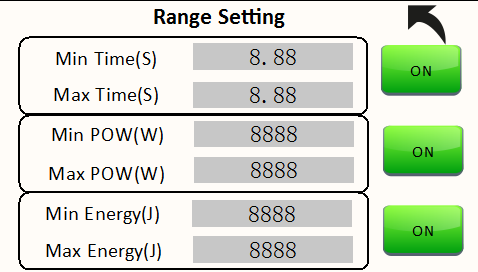

◆Quality management (time, energy mutual detection)

◆ welding record (operation statistics);

◆ powerful, high quality, high welding stability

C.Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |