20Khz Ultrasonic Welding Machine with Touch Screen for Automobile Welding

The principle of ultrasonic welding

The ultrasonic generator generates the signal frequency required by the ultrasonic transducer, and then uses the thermoplasticity of the plastic to generate heat at a very high speed between the molecules by using high-frequency friction between the working surfaces. When the heat is sufficient to melt, the ultrasonic wave is stopped. Vibration, at this time the workpiece joint is solidified by melting, complete the processing procedure! The traditional ultrasonic generator is manually frequency-modulated, and HZ-2000 digital ultrasonic generator realizes automatic frequency tracking, real-time power display, and friendly communication of human-machine interface!

The frequencies commonly used for plastic processing are 15 kHz and 20 kHz, of which 20 kHz is outside the human hearing range, so it is called ultrasonic, but 15 kHz is still in the human hearing range.

B.Function

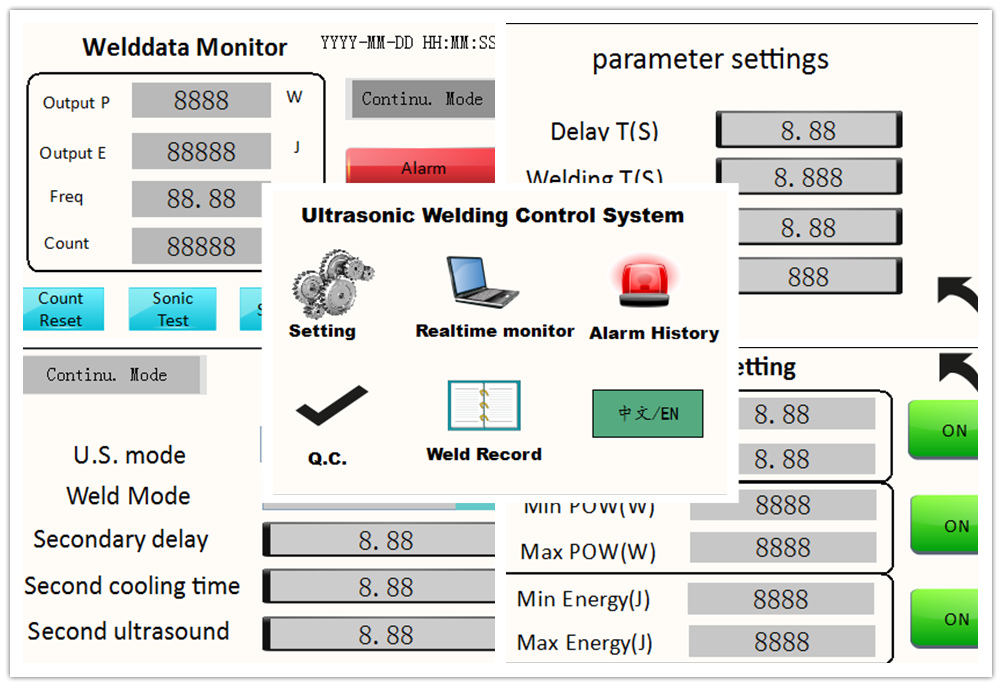

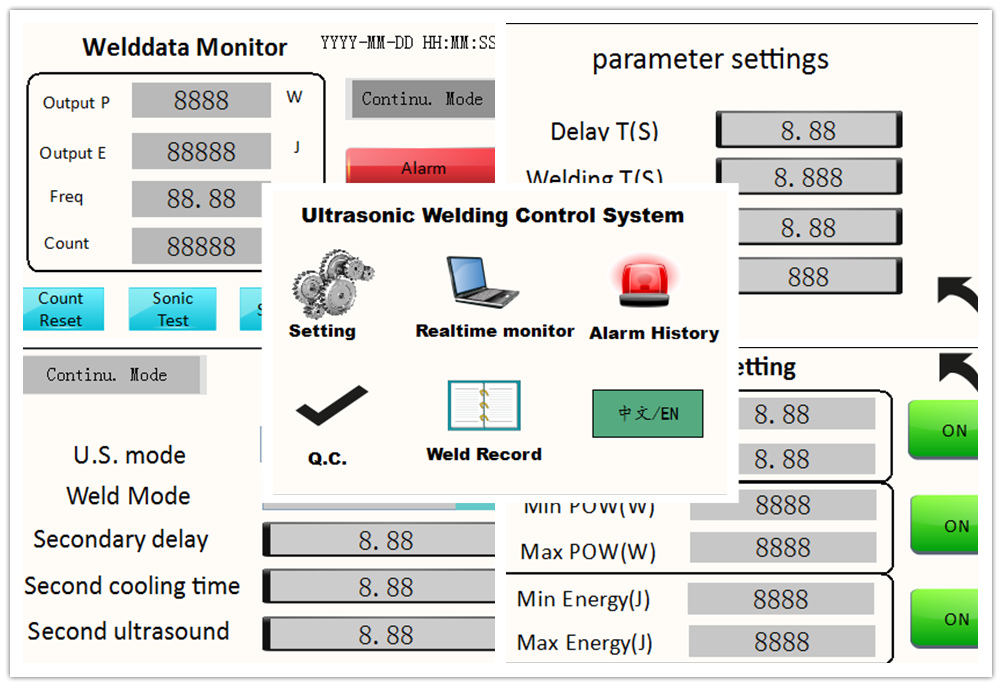

◆ Real-time frequency automatic tracking display;

◆ Welding mode: time, energy

◆Amplitude stepping function;

◆Welding amplitude 10-100 adjustable (1% accuracy)

◆Amplitude compensation

◆Mold impedance analysis + protection

◆Overload protection;

◆Quality management (time, energy mutual detection)

◆ welding record (operation statistics);

◆ powerful, high quality, high welding stability

C.Parameter

Power input specification: AC220V 50/60Hz or 110customized

Output power: 800W, 1000W, 1500W, 2500W, 3500W, 4500W

5000W big power need customize

Frequency of use: 15KHz, 20KHz, 28KHz, 30KHz, 35KHz 40KHz(optional)

Generator Dimensions: 430*200*130 (length * width * height)

Gross weight of generator : 6Kg.

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W /5000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |