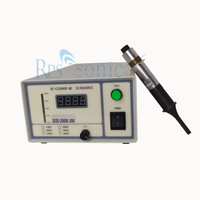

Ultrasonic Wire Embedding Equipment 70Khz Ultrasonic Probe

Ordinary ultrasonic embedding device, with the wear of the embedding horn (welding horn), the frequency is inevitably constantly changing (the product size determines the product frequency), when the frequency changes to a certain extent, it is difficult for the driving power source to find the frequency of the embedding horn. The digital ultrasonic embedding device introduced by our company has been upgraded in the tuning problem. Even if the embedding horn has a certain degree of wear, the driving power generator can quickly search and accurately find the frequency of the embedding horn, thus ensuring the stability of the entire ultrasonic system. jobs. The service life of the welding horn will be extended by 2-3 times, saving the loss for the majority of users. Compared with the similar products on the market, the power is increased by 30%. When working for a long time, the problem of matching the driving power and the embedding horn is improved. Our main ultrasonic embedding devices are available in 60K and 70K. The electric box can also be equipped with analog electric box and electric box only according to customer requirements.

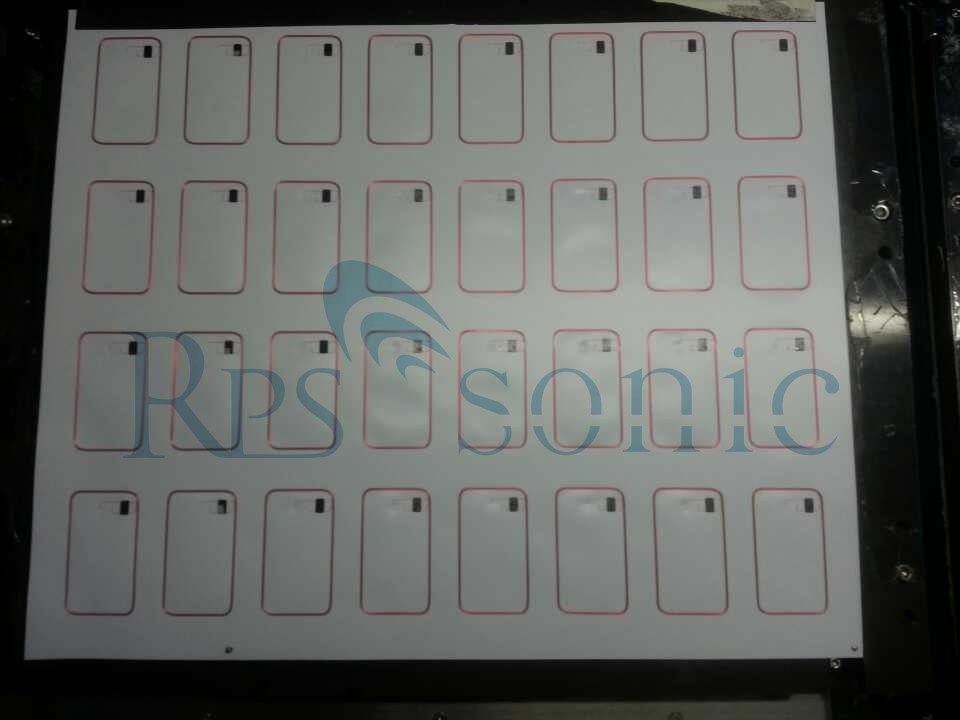

The features of smart card high-speed embedding equipment

◆Intelligent search frequency: automatic frequency function to extend the life of the plug.

◆Control mode: Touch screen control or external PLC control makes operation easier.

◆ Energy adjustment: 20%-100% energy can be continuously adjusted online, suitable for all types ofsmart card embedding applications ◆ Appearance: The body design is light, beautiful and durable, and the heat dissipation performance is good.

◆ Stability: 24 hours of work, uniform energy output.

◆Usage: Suitable for high-speed embedding applications. The embedding speed is twice the operation and description of the 60K equipment. Please refer to the attachment.

Advantage:

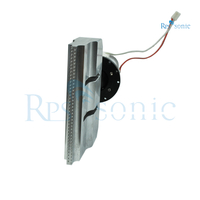

Intelligent search frequency, extend the life of buried wire head 2-3 times.

Do not dip tin before welding, reduce process and cost.

The matching power is strong, and the embedding horn and ultrasonic generator can be interchanged at will.

Multi - point power control, ultra-high-speed embedded line, good consistency.

It can work for a long time because it can solve the heating problem of the equipment when the wire is embedded.

Standardized design can directly replace imported products, environmental protection and safety.