Materials Used in Ultrasonic Spray Coating

The choice of materials in ultrasonic spray coating is crucial for achieving the desired coating properties and performance. It encompasses both the liquid materials used for atomization and the solid powders or suspensions that might be incorporated into the process. This section discusses the different types of materials employed in ultrasonic spray coating, their significance, and the implications of their use in varying applications.

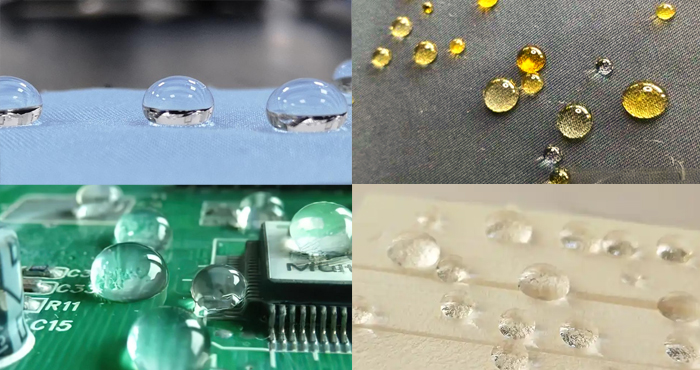

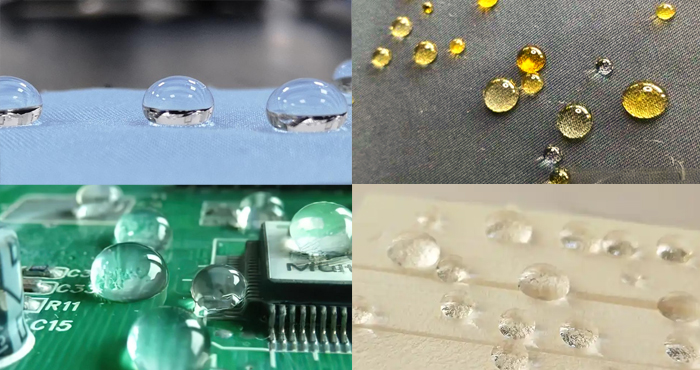

Liquid Materials: Liquid materials are the basis of the ultrasonic spray process. They are the primary substance that is atomized and applied to a surface. These can include solutions, suspensions, and emulsions formulated with various polymers, solvents, and additives. Each of these properties affects how the droplets behave when sprayed.

Polymers: Common liquid materials include thermoplastics and thermosetting polymers. Choices here can enhance the adhesion, flexibility, and tensile strength of the coating.

Solvents: The choice of solvent is essential as it affects the viscosity and volatility of the liquid. A well-chosen solvent aids the atomization process and ensures proper drying time.

Additives: Additives can modify properties such as flow, adhesion, and surface tension. Combining these ensures that the coating meets specific performance criteria.

In essence, the right combination of liquid materials can improve the efficiency of the coating process, allowing for uniform application and optimized properties of the coated surface.

Solid Powders and Suspensions

Solid powders and suspensions can also play a key role in ultrasonic spray coatings. Their combination with liquid materials creates unique properties and enhances the functionality of the coating. These solid additives can be metals, ceramics, or specialized composites.

Metals: Using metal powders in coatings can improve conductivity and create functional surfaces. Applications may be found in the electronics or automotive industries.

Ceramics: Ceramic powders are used when high wear and corrosion resistance is required. For example, they are widely used in aerospace and biomedical applications.

Composites: Adding composites can provide a balance of properties, combining the strengths of various materials to meet specific mission criteria.

These inclusions can enhance performance, but also require precise control during the coating process to ensure the correct distribution of the solid components.

Material Compatibility

Material compatibility is important when discussing ultrasonic spray coatings. It examines how different materials interact with each other during the coating process. Poor compatibility can lead to a variety of problems such as delamination, ineffective bonding, or inconsistent coating quality.

Chemistry: Understanding the chemistry of each material is fundamental. The interaction between the liquid and solid materials must be optimized to ensure the expected performance results.

Temperature Stability: Some materials may have limits on the temperatures they can withstand. If the coating process exceeds these limits, degradation or changes in performance can result.

Application Method: Compatibility also involves the application method. Certain materials may require precise nozzle configurations or specific ultrasonic frequencies to work effectively.

Successful ultrasonic spray coating depends on a sophisticated understanding of how these different materials interact during and after application. By considering these elements, manufacturers can achieve advanced functional coatings suitable for a wide range of applications.

Ultrasonic Spray Equipment and Devices

The efficiency and effectiveness of ultrasonic spraying depends largely on the equipment and devices used in the spraying process. The precise configuration and integration of the various components are critical to achieving the desired results of the coating application. Each part of the setup must work together seamlessly to ensure optimal performance, consistency and repeatability in the coating application.

Nozzle Configuration

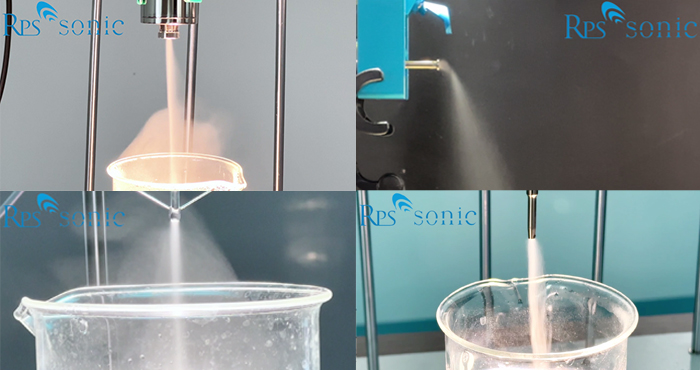

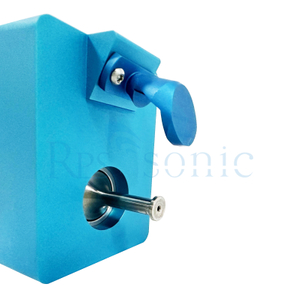

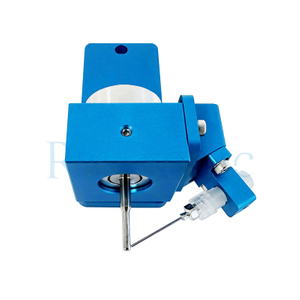

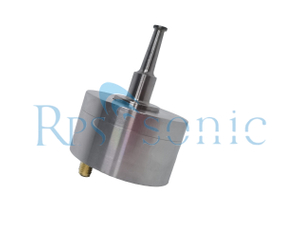

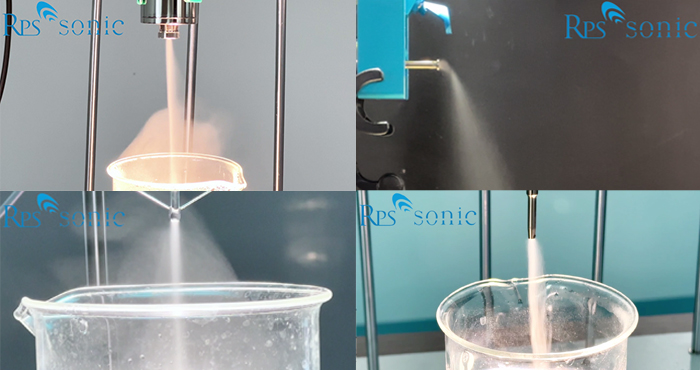

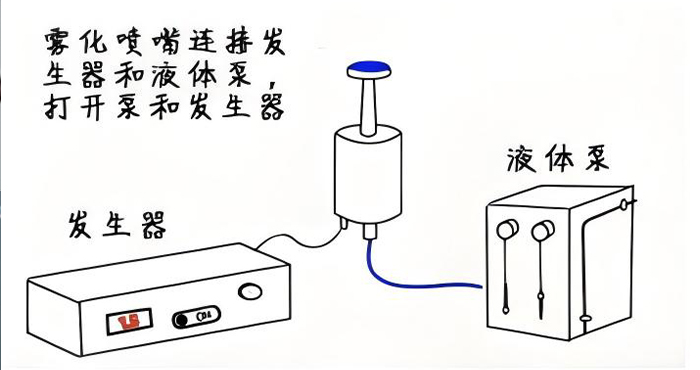

Nozzles are an important part of the ultrasonic spray system. They play a key role in the atomization process. The configuration of the nozzle determines how the coating material is delivered to the substrate surface.

Different types of nozzles affect the droplet size and spray pattern, which directly affects the uniformity of the coating. Choices include direct and indirect nozzles, which provide different degrees of control over spray characteristics. For example, dual fan nozzles can promote a wider spray, allowing a larger area to be covered with minimal overlap, thereby improving the efficiency of material use.

It is also important to consider factors such as nozzle diameter, length and position to optimize the atomization energy and ensure proper interaction with the ultrasound. Keep these configuration aspects in mind when designing your ultrasonic spray application.

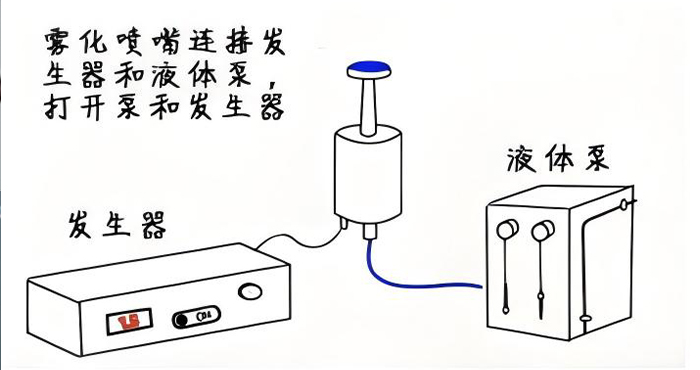

Fluid Delivery System

The fluid delivery system is another critical element of an ultrasonic spray unit. The system must accurately deliver liquid materials from the tank to the nozzle without introducing air bubbles or contaminants.

Typically, these systems employ peristaltic or syringe pumps to maintain consistent flow rates and pressures. Proper fluid delivery ensures that the right amount of material reaches the nozzle at the correct viscosity, helping to optimize the performance of the spray. Viscosity has a significant impact on droplet formation and spray consistency; therefore, the delivery system must accommodate changes in fluid properties.

Additionally, the materials used in the delivery system should be considered to avoid chemical reactions with the coating material. Compatibility between the fluid delivery components and the material being sprayed must be ensured to prevent clogging and other flow disruptions.

Control and Monitoring Systems

Control and monitoring systems are the backbone of an effective ultrasonic spray operation. These systems enable real-time adjustments and ensure that process parameters remain within the desired range.

Advanced ultrasonic spray units typically use computer-aided control systems that allow precise modulation of parameters such as spray time, amplitude, and frequency. By continuously monitoring variables, these systems help maintain optimal processing conditions and take corrective action when deviations occur.

English

English