Introduction

Rubber is a material widely used in various industries, such as machinery, automobiles, engineering, etc. Traditional rubber cutting methods require a lot of energy and a relatively long time to process, and also introduce some unnecessary dangers. In addition, due to the heat and friction during the cutting process, the rubber material will be damaged. In order to solve the shortcomings of traditional cutting methods, people have developed ultrasonic rubber cutting knives, which have brought revolutionary changes to rubber cutting.

Common rubber cutting methods

1. Mechanical cutting method

Mechanical cutting is a common and effective method for cutting rubber. This method is suitable for synthetic rubbers such as silicone rubber, fluororubber, polyurethane rubber, chloroprene rubber and polytetrafluoroethylene. Common mechanical cutting equipment includes sawing machines, grinding wheel cutters, shearing machines, etc. When using the mechanical cutting method, it is necessary to keep the knife sharp and control the quality and efficiency of the cutting by adjusting the cutting speed and knife pressure.

2. Thermal cutting method

Thermal cutting is a method of cutting solid rubber by heating. Common thermal cutting methods include flame cutting, hot knife cutting and laser cutting. These methods are suitable for various rubber materials, especially synthetic rubber. In flame cutting, oxygen and fuel are used to create flames, and the heat of the flame is used to cut rubber. Hot knife cutting uses a heated blade to cut rubber. Laser cutting uses a laser beam to cut rubber. When using the thermal cutting method, it is necessary to control the heating temperature, cutting speed and contact time of the tool to avoid burning, melting or cutting marks of the plastic.

3. Water cutting method

Water cutting is a non-contact cutting method that cuts rubber with a high-pressure water flow and abrasive mixture. This method is suitable for various rubber materials, especially for high-precision and complex-shaped cutting requirements. Water cutting does not cause problems such as thermal deformation and gas pollution, and can achieve high-speed cutting, saving energy and materials. When using the water cutting method, it is necessary to adjust the water pressure, nozzle shape and cutting speed to control the cutting effect.

4. Ultrasonic cutting method

Ultrasonic cutting is a method of cutting rubber using ultrasonic vibration. Ultrasonic cutting can not only be used to cut rubber, but also some thin-walled plastic materials, such as various membrane materials, composite materials, etc. This method can achieve high-speed and high-efficiency cutting without the problem of melting area and thermal deformation. When using the ultrasonic cutting method, it is necessary to select the appropriate amplitude and frequency, as well as adjust the cutting speed to achieve the best cutting effect.

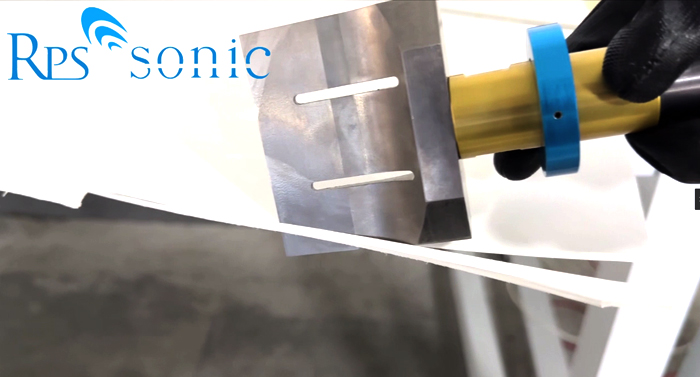

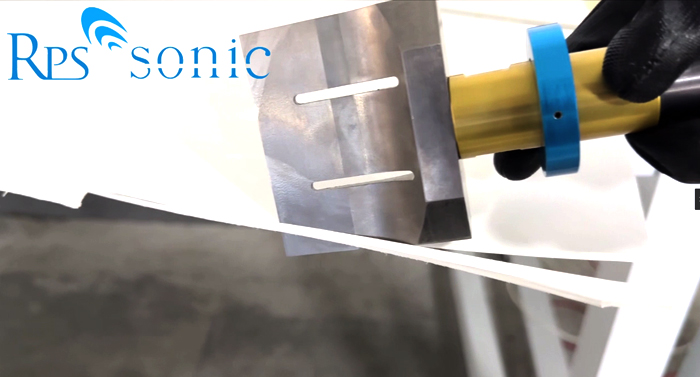

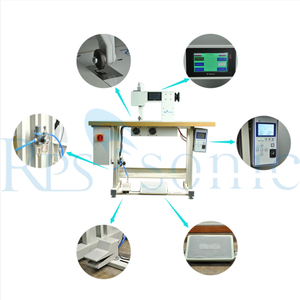

Due to customer demand, our company has also successfully developed a rubber cutting knife. Let's take a look at our rubber cutting knife!

1. What is an ultrasonic rubber cutting knife?

Ultrasonic rubber cutting knife is a new technology that uses ultrasonic energy to cut rubber. Rubber materials generally have high toughness. Ultrasonic rubber cutting knives generate high-frequency mechanical vibrations to rapidly heat up the internal friction of rubber materials to achieve the purpose of precise cutting.

2. Advantages of ultrasonic rubber cutting knives:

Efficiency:

Using ultrasonic rubber cutting knives can quickly and accurately cut rubber. Compared with the traditional mechanical trenching method, the efficiency of ultrasonic rubber cutting knives has been greatly improved.

High precision:

Ultrasonic rubber cutting knives have high-precision cutting capabilities and can cut complex shapes, sizes and edges without damaging materials.

Ecological environmental protection:

Ultrasonic rubber cutting does not require lubricants or chemicals, and the noise and pollutants generated are very small, which greatly reduces the impact on the environment.

Safety:

Traditional mechanical cutting is prone to tool slippage or interference, which is dangerous. Ultrasonic rubber cutting knife re-cutting.

Reduce heat and friction during cutting, and reduce danger during cutting.

3. Application of ultrasonic rubber cutting:

Automotive industry: Ultrasonic rubber cutting knife can be used for cutting rubber in automobile tires, processing of car window sealants, etc.

Medical equipment: Ultrasonic rubber cutting knife can be used for cutting rubber materials in surgical operations, such as surgical gloves, dental impressions, etc.

Electronic product manufacturing: Ultrasonic rubber cutting knife can be used for cutting mobile phone films and various electronic parts.

Other applications:

Ultrasonic rubber cutting knife is also used for cutting and processing in the fields of fabrics, resins, plastics, food, etc.