Ultrasonic spray coating technology plays a vital role in a wide range of industries by providing innovative solutions to complex problems. This section delves into specific areas of ultrasonic spray coating applications, highlighting its capabilities and benefits. From enhancing product functionality to improving manufacturing processes, understanding these applications helps to realize the relevance of this technology. The following are the major areas where ultrasonic spray coatings have shown a significant impact.

Biomedical Applications

In the biomedical field, ultrasonic spraying is a revolutionary technology. It is used to create thin films for drug delivery systems, allowing for uniform coating of drug compounds. By adopting this approach, precise dosing can be achieved on medical devices such as stents and implants. The ability to control droplet size enhances drug absorption and biocompatibility, making treatments more effective. In addition, coatings applied through ultrasonic spraying can prevent biofilm formation on the surface, significantly improving the lifespan and performance of the device.

The advantages of using ultrasonic spray coatings in biomedical applications include:

Uniformity: ensures consistent surface thickness.

Versatility: compatible with a wide range of materials and drug compounds.

Efficiency: reduces waste and optimizes production time.

Overall, this technology holds promise for advancing biomedical engineering and improving patient outcomes.

Electronics and Semiconductor Industry

In the electronics industry, ultrasonic spraying is essential for manufacturing high-performance components. Its precision in applying coating materials makes it suitable for creating conformal coatings on printed circuit boards and semiconductor devices. These coatings protect against moisture, corrosion and other environmental factors, ensuring the reliability and longevity of electronic products.

In addition, ultrasonic spraying allows the integration of functional materials, such as conductive inks and dielectric layers. The ability to customize thickness and material properties has enabled advances in the miniaturization and efficiency of electronic components. Notable benefits include:

Enhanced protection: Protect sensitive components from external threats.

Cost-effectiveness: Minimize material waste while maximizing coverage.

Improved performance: Facilitates the production of high-quality electronic devices.

As a result, ultrasonic spraying has changed the way electronic products are developed and manufactured, driving innovation in the industry.

Automotive and Aerospace Applications

The automotive and aerospace industries have also clearly benefited from ultrasonic spray coatings. In the automotive manufacturing industry, this technology is used to apply protective coatings on components such as engines, landing gear and body panels. The uniform application of the coating helps prevent rust and corrosion, improving the durability and aesthetics of the vehicle.

In the aerospace sector, weight reduction is critical and ultrasonic spray coating contributes by allowing the use of lightweight materials without compromising protection. It is used to apply thermal barrier coatings on engine components and for surface modification to enhance aerodynamic performance.

New Energy Industry:

(1) Solar Cells: Active layers and transparent conductive oxide (TCO) coatings for perovskite cells, with thickness controlled at submicron level, improve photoelectric conversion efficiency while reducing material loss by more than 80%.

(2) Fuel Cells: Precision spraying of platinum catalysts on proton exchange membranes, with a utilization rate of 90% (conventional methods are only 30%), forming a porous catalytic layer to improve reaction efficiency.

(3) Lithium-ion/solid-state batteries: Ultra-thin coatings of electrode materials increase energy density by 15%, optimize electrolyte wettability, and extend cycle life.

Key points of these applications include:

Durability: Coatings improve the service life and performance of vehicle components.

Weight Efficiency: Ensures efficient use of lightweight materials.

Precision: Applications customized according to performance requirements and specifications.

Overall, ultrasonic spray coating stands out as a solution that can meet the demanding requirements of automotive and aerospace manufacturing, making vehicles and aircraft safer and more efficient.

Advantages of Ultrasonic Spraying

The application of ultrasonic spray coatings has significant advantages that have had a significant impact on various industries. Understanding these benefits is essential to effectively utilize this technology. The main advantages include efficiency and precision, reduced material waste, and improved coating uniformity. Each of these factors plays a vital role in motivating companies to adopt ultrasonic spray methods instead of traditional technologies.

Efficiency and Precision

Ultrasonic spraying is known for its high efficiency and high precision. The ultrasonic atomization process allows for finer droplet sizes, thereby ensuring better coverage of the target surface. This technology allows the coating to be applied evenly, reducing the possibility of imperfections. In addition, the precision of the spray pattern can be adjusted, which means that specific areas can be treated without unnecessary overspray.

This level of control is particularly valuable in industries such as electronics and biotechnology, where coating accuracy is critical. In these scenarios, even small differences in coverage can lead to significant performance differences.

Reduced Material Waste

One of the most significant advantages of ultrasonic spray coating is the reduction of material waste. In traditional spraying methods, a significant amount of material is lost due to overspray or poor orientation. However, with the development of ultrasonic technology, the efficiency of material use has been greatly improved. Because the formation of droplets is finely tuned, less material is needed to obtain the same amount of coverage.

Potential Developments in Materials

The development of materials is equally critical to the future of ultrasonic spray coatings. The creation of new coating materials that exhibit excellent properties can drive this technology forward. For example, bio-based materials are gaining interest. They can open up new avenues in industries such as the biomedical field, where sustainability is becoming a priority.

In addition, adjusting the properties of existing materials can bring significant improvements. This includes changing viscosity and surface tension properties. By focusing on the compatibility of materials with the process, manufacturers can better control the end result. Therefore, it is imperative that research into materials innovation continues vigorously.

Innovative Applications on the horizon

The potential for innovative applications of ultrasonic spray coatings is huge. One notable area is the electronics industry, especially with the rise of flexible and wearable technology. Ultrasonic spraying can provide effective and uniform coatings on thin substrates, which is essential for these applications.

In addition, there is also promise in protective coatings for the automotive and aerospace sectors. Providing coatings that are lighter yet still protective and durable is an ongoing challenge. Ultrasonic spray coatings can provide a solution, allowing for the precise application of these desirable materials.

“The future of ultrasonic spray coatings is promising as innovative technologies and materials drive new applications across industries.”

These future directions require focused research. As awareness and understanding grow, the industry will benefit greatly from the development of this technology.

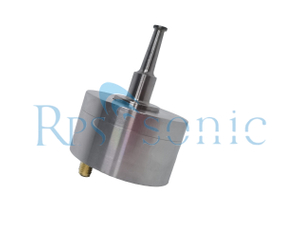

RPS-SONIC Ultrasonic spraying equipment videos: