Ultrasonic sealing and cutting equipment is widely used in the cutting of textiles, woven bags/plastics, etc. and their downstream processing. Many of these uses are based on the ability to use ultrasonic energy to generate heat and pressure through vibration action. The use of ultrasonic sealers and cutters makes the production of nonwovens and non-woven fabrics economical and process safe, which is of great value to our customers from the medical, packaging, textile and engineering industries.

With our ultrasonic sealers and cutters, we are able to separate accurately and quickly and weld the edges in a delicate and reliable manner. The main advantages of the ultrasonic sealing and cutting method are that the edges of the textile material, when cut at the same time, are sealed by the dissipation of ultrasonic energy, thus preventing the occurrence of frayed edges or unraveling of the threads, the fabric will not discolor, the edges are very strong, uniform, smooth, clean and durable, there is no over-thickness, and the energy consumption is low.

Hangzhou Gonglu Ultrasonic Equipment Co., Ltd. produces a range of ultrasonic sealers and ultrasonic cutting systems that provide effective sealing and optimal functionality. These products are recognized for their efficient operation and reliability.

Ultrasonic sealer and cutter systems are mainly used for the sealing of materials such as fabrics, plastic films, composite papers, non-woven fabrics, filters, etc. This is a versatile machine that is being offered in a range of frequencies and powers. Typical applications of this system include protective clothing, disposable hospital gowns, shoe covers, masks, baby care clothing, filters, bags, curtains, sails and mesh stitching. Sealed edges and seams, without sewing holes, prevent the penetration of chemicals, liquids, blood, pathogens or particles, thus providing the benefits of a traditional sewing method.

1. Basic Principle

Ultrasonic energy: Generates heat through high-frequency vibration (usually 20kHz-40kHz) to melt the fabric locally.

Pressure cutting: The ultrasonic generator converts electrical energy into mechanical vibration, which is transmitted to the fabric through the welding head, and the cutting and edge sealing are completed synchronously at the moment of pressure.

2.Features:

1. The cutting incision is smooth, reliable, and the edge cutting is accurate; efficient and accurate: the cutting speed can reach 20-30 meters/minute, and the accuracy can reach ±0.5mm, which is suitable for complex shapes.

2. The edge can be sealed during cutting without deformation or warping;

3. No linting, no silk loss, no wrinkling, and no edge after cutting;

4. Stable operation, fast cutting speed, no sticking knife, etc.;

5. Easy to operate, no need for professionals, saving time and effort;

6. Workers will not get tired after long-term operation;

7. Strong power and good stability;

8. High-quality round knife rolling cutting, wear-resistant and durable.

Wide material adaptability: Especially suitable for chemical fibers (polyester, nylon, etc.), parameters need to be adjusted for natural fibers (cotton, linen).

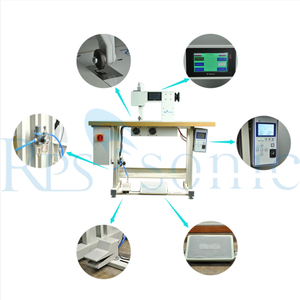

3.Equipment composition

Ultrasonic generator: provides 15kHz-40kHz adjustable frequency, power 300W-3000W.

Transducer: piezoelectric ceramic conversion efficiency> 90%.

Welding head (tool head): titanium alloy material, amplitude 50-100μm, life of about 2000 hours.

Workbench: CNC system supports CAD drawing import, repeat positioning accuracy 0.1mm.

4.Process parameters

Pressure: 0.2-0.6MPa (depending on material thickness)

Action time: 0.1-0.5 seconds

Amplitude: 30-70μm (thick materials require larger amplitude)